Nonmetal co-doped ZnO transparent conducting thin film with high migration rate and preparation method thereof

A technology of transparent conductive film and high mobility, which is applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve the problem that the conductivity of pure ZnO cannot meet the needs of use, and achieve the advantages of electron mobility, Fast conductivity, smooth growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

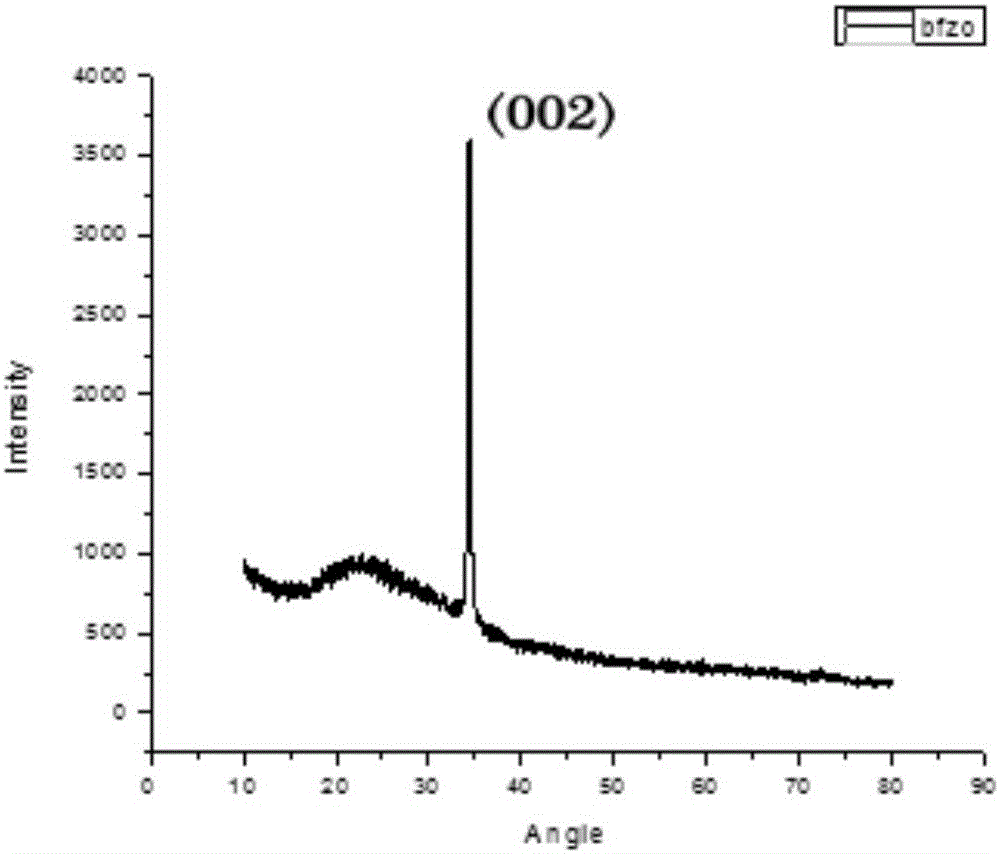

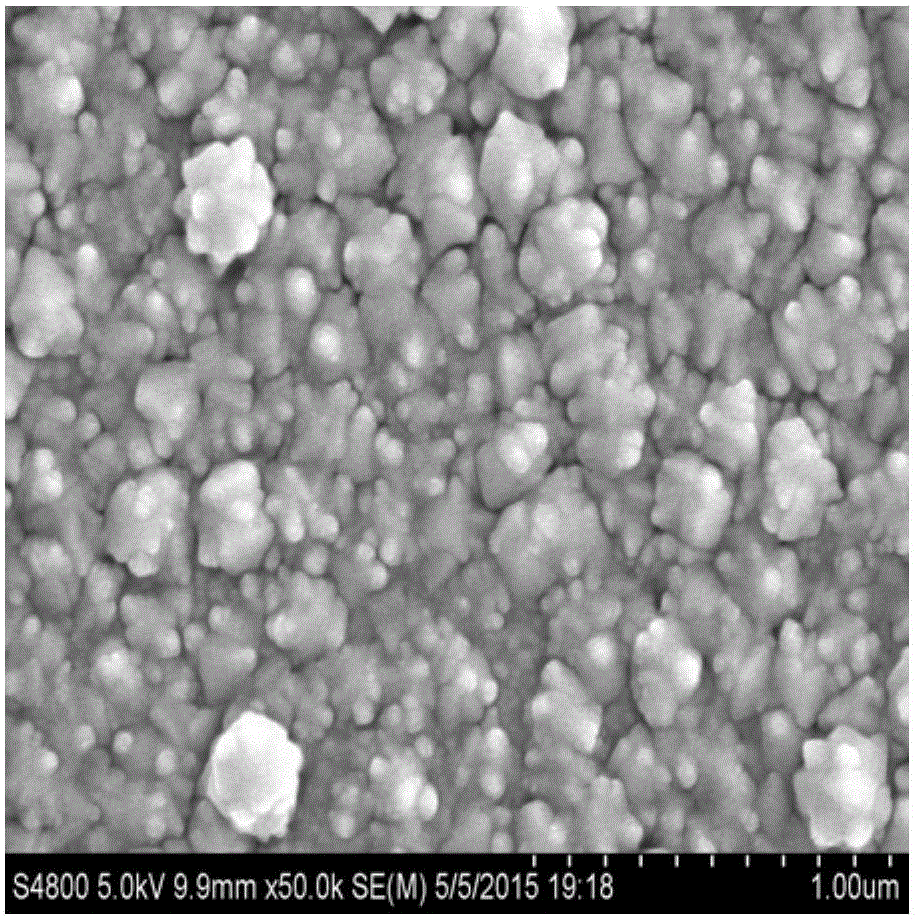

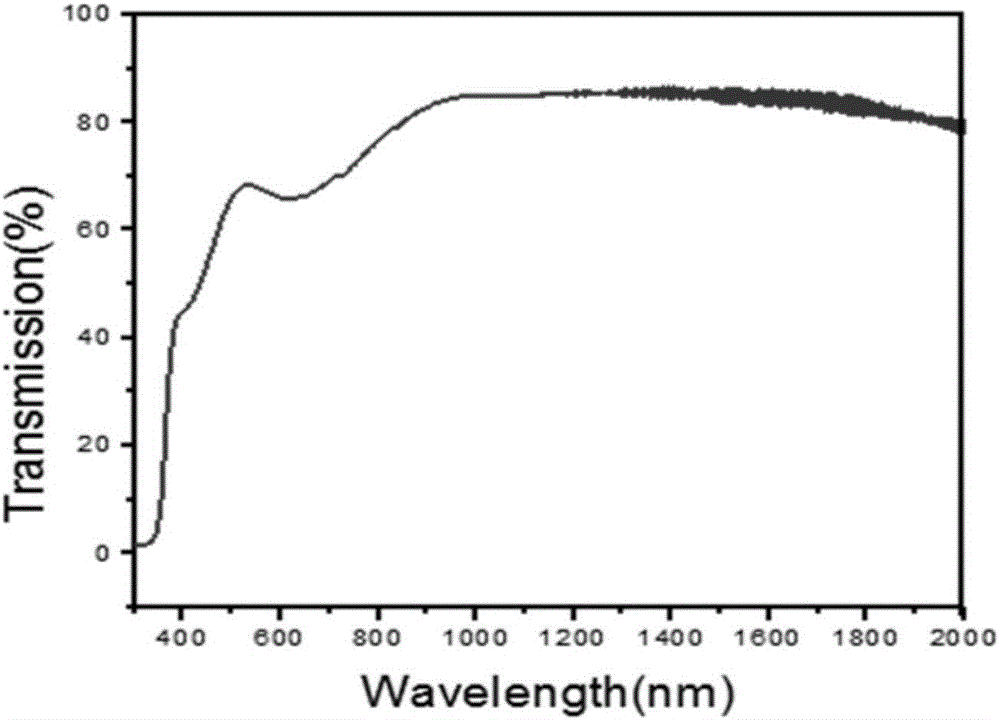

Embodiment 1

[0031] 1) Target preparation: according to Zn 0.92 B 0.02 f 0.06 The ratio of O to prepare BFZO ceramic targets, where the atomic ratio of B and F is 2:6;

[0032] 2) Clean the polycarbonate (PC) substrate with acetone and ethanol with an ultrasonic cleaner for 10 minutes, repeat twice, take it out, dry it with Ar gas, and place it on the substrate tray of the magnetron sputtering equipment;

[0033] 3) After installing the BFZO ceramic target, close the chamber door, turn on the mechanical pump and the molecular pump and start vacuuming until the vacuum degree reaches 5×10 -6 Torr, start the substrate heating program, and heat the substrate to 60°C;

[0034] 4) Feed pure Ar into the growth chamber, adjust the air pressure to 12mTorr and start glowing, and pre-sputter for 5 minutes to remove impurities on the target surface;

[0035] 5) Open the sputtering baffle, adjust the growth pressure to 8mTorr, turn on the RF power supply, set the power to 100W, and sputter for 1h t...

Embodiment 2

[0040] 1) Target preparation: according to Zn 0.95 B 0.02 S 0.03 The ratio of O to prepare BSZO targets, where the atomic ratio of B and S is 2:3;

[0041] 2) Clean the polycarbonate (PC) substrate with acetone and ethanol with an ultrasonic cleaner for 10 minutes, repeat twice, take it out, dry it with Ar gas, and place it on the substrate tray of the magnetron sputtering equipment;

[0042] 3) After installing the BSZO ceramic target, close the chamber door, turn on the mechanical pump and the molecular pump to start vacuuming until the vacuum degree reaches 5×10 -6 Torr, start the substrate heating program, and heat the substrate to 60°C;

[0043] 4) Feed pure Ar into the growth chamber, adjust the air pressure to 12mTorr and start glowing, and pre-sputter for 5 minutes to remove impurities on the target surface;

[0044] 5) Open the sputtering baffle, adjust the growth pressure to 8mTorr, turn on the RF power supply, set the power to 100W, and sputter for 1h to obtain ...

Embodiment 3

[0048] 1) Target preparation: according to Zn 0.92 B 0.02 Cl 0.06 Prepare B and Cl co-doped ZnO targets with the ratio of O, where the atomic ratio of B and Cl is 2:6;

[0049] 2) Clean the polycarbonate (PC) substrate with acetone and ethanol with an ultrasonic cleaner for 10 minutes, repeat twice, take it out, dry it with Ar gas, and place it on the substrate tray of the magnetron sputtering equipment;

[0050] 3) After installing the BClZO ceramic target, close the chamber door, turn on the mechanical pump and the molecular pump to start vacuuming until the vacuum degree reaches 5×10 -6 Torr, start the substrate heating program, and heat the substrate to 60°C;

[0051] 4) Feed pure Ar into the growth chamber, adjust the air pressure to 12mTorr and start glowing, and pre-sputter for 5 minutes to remove impurities on the target surface;

[0052] 5) Open the sputtering baffle, adjust the growth pressure to 8mTorr, turn on the RF power supply, set the power to 100W, and spu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com