A kind of preparation method of nitrocellulose molecularly imprinted electrochemical sensor

A nitrocellulose and molecular imprinting technology, which is applied in the fields of electrochemical variables of materials, scientific instruments, instruments, etc., can solve the problems of inability to detect nitrocellulose by X-rays, cumbersome follow-up processing, and large instrument volume, etc. The effect of simple preparation method and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

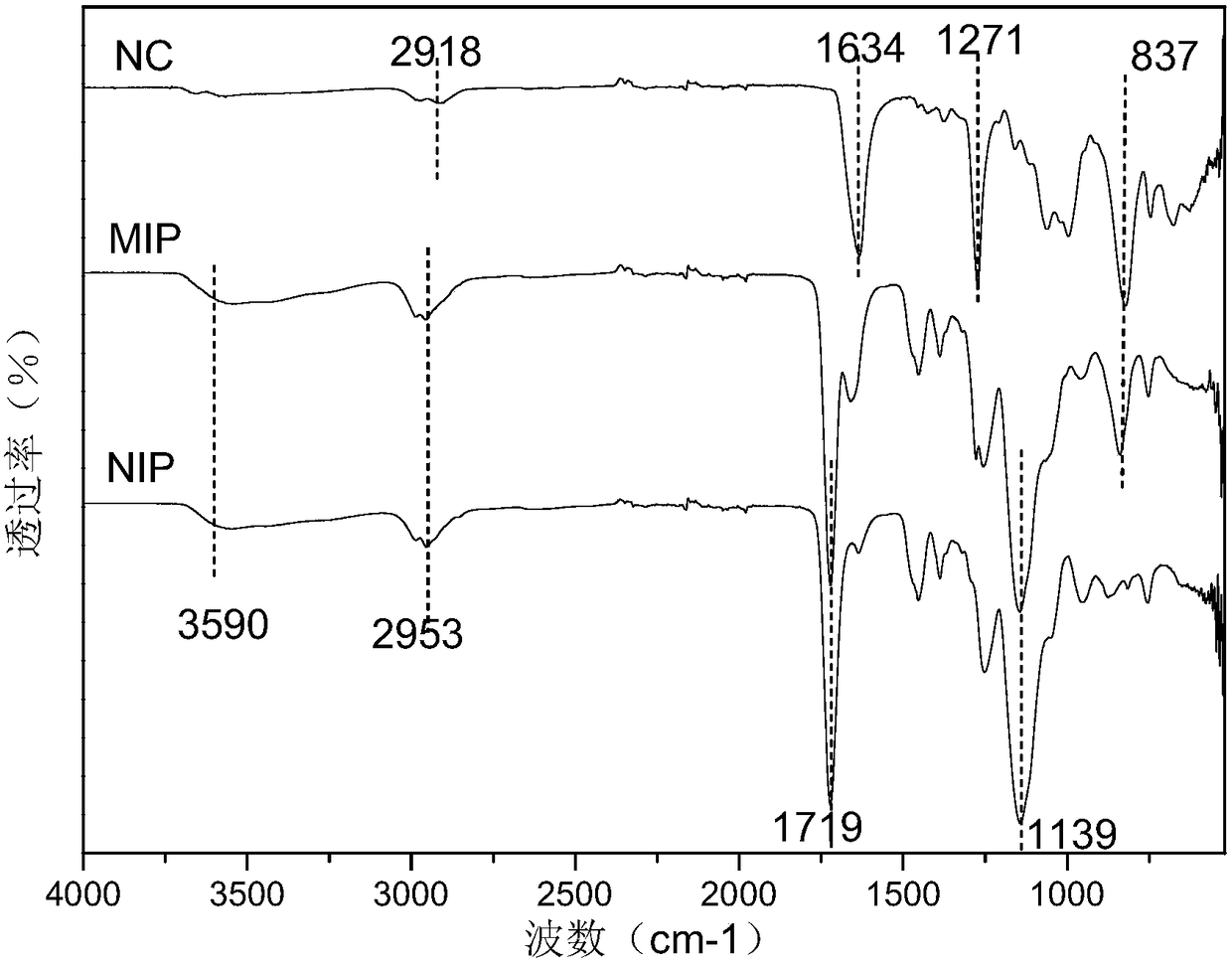

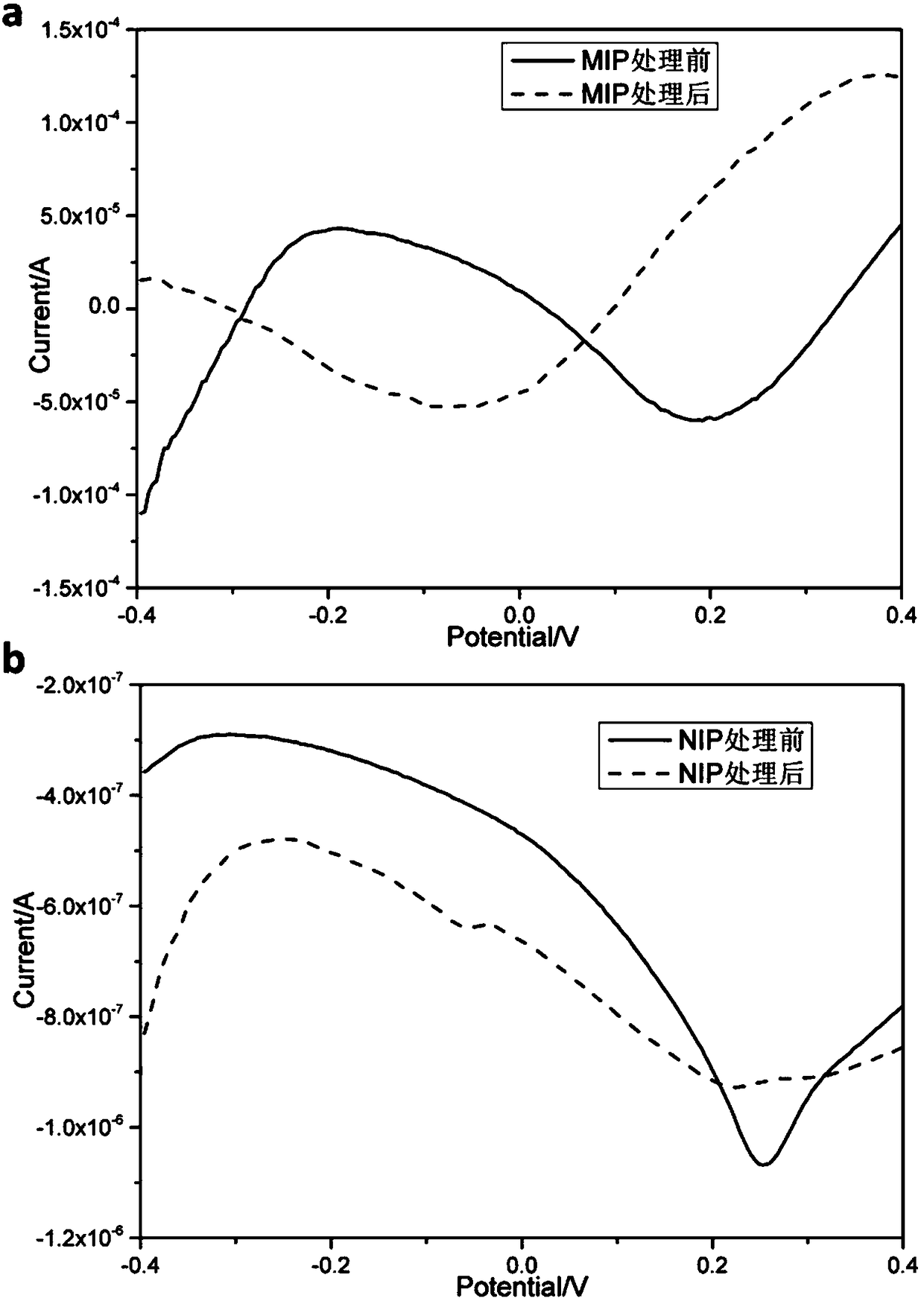

[0020] Preparation of nitrocellulose molecularly imprinted polymers:

[0021] Accurately weigh NC0.3107g, add 30mL acetone to dissolve. After the NC was completely dissolved, 0.28mL (3.33mmol) of MAA and 1mL (5.31mmol) of EGDMA were added, and the mixture was ultrasonically oscillated for 10min at room temperature to fully contact the template NC with the monomer MAA and the cross-linking agent EGDMA.

[0022] Pour the ultrasonically oscillated liquid into a 4-neck flask, add 0.2189 g (1.33 mmol) of initiator AIBN, and fix it on the iron stand supporting the constant temperature water tank. Install the condenser tube and the stirring paddle, turn on the power of the agitator, change the speed, and adjust the stirring paddle to make it in a suitable position. Vacuum the polymerization system, wait for the vacuum degree to exceed 0.1Mpa and last for one minute, indicating that the system has basically reached the vacuum condition, connect the nitrogen pipe, and fill the polymer...

Embodiment 2

[0028] Preparation of nitrocellulose molecularly imprinted polymers:

[0029] Accurately weigh NC0.3115g, add 30mL acetone to dissolve. After the NC was completely dissolved, 0.28mL (3.33mmol) of MAA and 2mL (10.61mmol) of EGDMA were added, and the mixture was ultrasonically oscillated for 10min at room temperature to fully contact the template NC with the monomer MAA and the cross-linking agent EGDMA.

[0030] Pour the ultrasonically oscillated liquid into a 4-necked flask, add 0.2187 g (1.33 mmol) of initiator AIBN, and fix it on the iron frame supporting the constant temperature water tank. Install the condenser tube and the stirring paddle, turn on the power of the agitator, change the speed, and adjust the stirring paddle to make it in a suitable position. Vacuum the polymerization system, wait for the vacuum degree to exceed 0.1Mpa and last for one minute, indicating that the system has basically reached the vacuum condition, connect the nitrogen pipe, and fill the poly...

Embodiment 3

[0034] Preparation of nitrocellulose molecularly imprinted polymers:

[0035] Accurately weigh NC0.3115g, add 30mL acetone to dissolve. After the NC was completely dissolved, 0.28mL (3.33mmol) of MAA and 4mL (21.24mmol) of EGDMA were added, and the mixture was ultrasonically oscillated for 10min at room temperature to fully contact the template NC with the monomer MAA and the cross-linking agent EGDMA.

[0036] Pour the ultrasonically oscillated liquid into a 4-necked flask, add 0.2187 g (1.33 mmol) of initiator AIBN, and fix it on the iron frame supporting the constant temperature water tank. Install the condenser tube and the stirring paddle, turn on the power of the agitator, change the speed, and adjust the stirring paddle to make it in a suitable position. Vacuum the polymerization system, wait for the vacuum degree to exceed 0.1Mpa and last for one minute, indicating that the system has basically reached the vacuum condition, connect the nitrogen pipe, and fill the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com