Optical filter based on graphene

An optical filter device and graphene technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of small quality factor, non-tunable, high loss, etc., and achieve the effect of large quality factor, reduced size, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

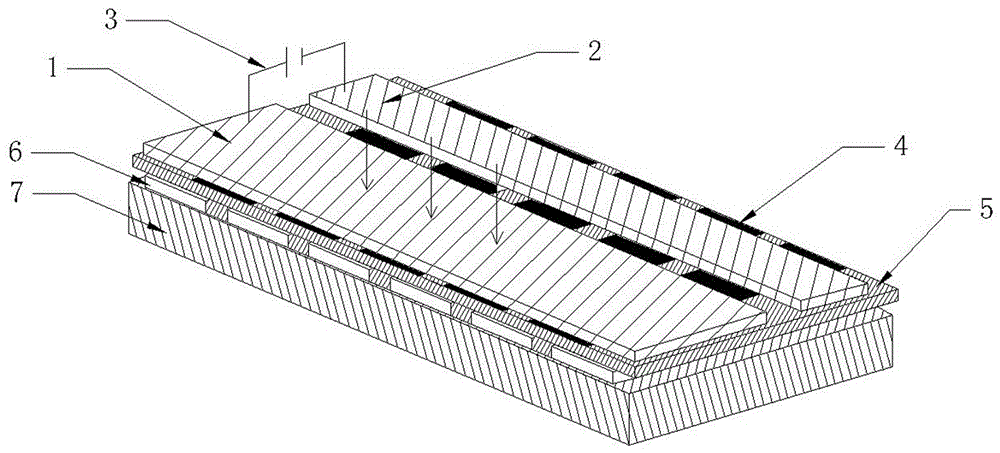

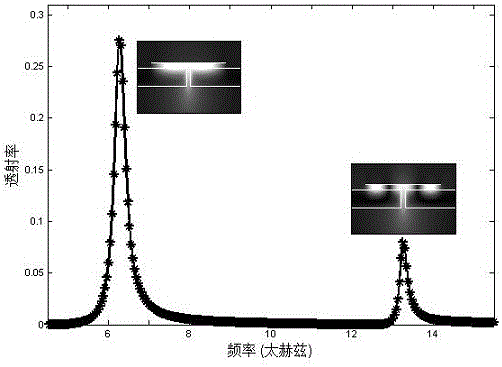

[0028] A beam of parallel light with a wavelength in the infrared band is vertically incident on the electrolyte layer, and the incident light is TM mode (the magnetic field component is perpendicular to the incident surface). The thickness of the electrolyte layer and the metal electrode is 300nm, the period of the graphene strip array and the metal grating is 8000nm or 8 microns, the bandwidth of the graphene strip in the graphene strip array is 720nm, and the gap width of two adjacent metal strips in the metal grating The thickness of silicon dioxide dielectric, metal grating and substrate silicon carbide are 20, 80 and 500nm respectively. The carrier mobility and Fermi velocity of graphene are 20000 cm 2 / (Vs) and 10 6 m / s, the metal grating in this embodiment is a gold grating, and a silver grating can be used in other embodiments. Adjust the top gate voltage V g Let the Fermi level of graphene be 0.6eV. Under the above parameters, it can be obtained as figure 2 The...

Embodiment 2

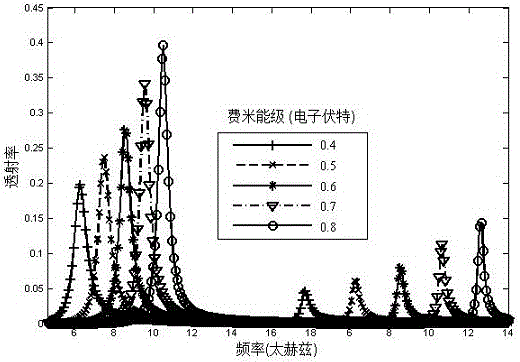

[0031] The Fermi level of graphene can pass the top gate voltage V g Make adjustments. The change of the Fermi level of graphene leads to the change of the coupled electromagnetic mode propagation constant (effective refractive index) of the Fabry-Perot microcavity, which changes the response frequency of the microcavity. image 3 is the transmission spectrum at different Fermi levels (other parameters are the same as in Example 1). When the Fermi level of graphene increases from 0.4eV to 0.8eV, the two transmission peaks on the left and right are blue-shifted, the magnitudes of the blue shifts are 2.1 and 4.5THz, and the speeds of the blue shifts are 0.53 and 1.12THz / eV, respectively. The two transmission peaks increase as the Fermi level increases, and the quality factor increases accordingly. When the Fermi level reaches 0.8 electron volts, the quality factors of the left and right transmission peaks reach 28 and 89, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com