Multilayer film with strong vertical magnetic anisotropy

An anisotropic, multi-layer film technology, applied in the field of non-volatile magnetic memory and magnetic logic, can solve the problem of not meeting the requirements of magnetic random access memory, insufficient thermal stability of double-interface structure, increasing the number of film layers in double-interface structure, etc. problem, to achieve the effect of reducing critical switching current, strong perpendicular magnetic anisotropy and thermal stability, and small critical switching current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

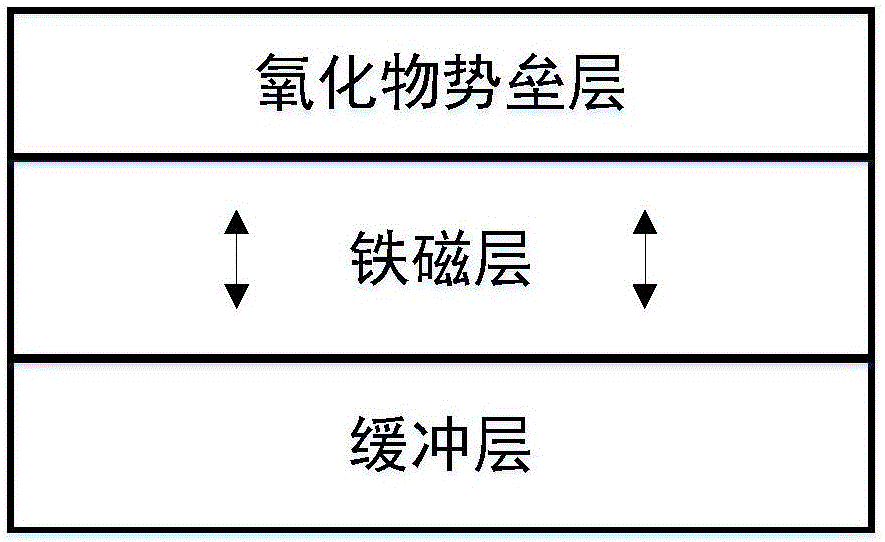

[0059] This embodiment is a specific example of solution one. In this embodiment, the buffer layer, the ferromagnetic layer and the oxide barrier layer are deposited on the thermally oxidized silicon substrate in order from bottom to top by magnetron sputtering, and the oxide barrier layer is deposited on the A protective layer such as Figure 4 shown. Finally, photolithography, etching and other processing are carried out, and the cross-sectional area is circular.

[0060] Among them, the buffer layer material is Bi with a thickness of 1nm; the ferromagnetic layer material is Co 20 Fe 60 B 20 , the thickness is 2.5nm; the oxide barrier layer material is MgO, the thickness is 1nm; the protective layer material is Ta, the thickness is 5nm. Because the Bi / CoFeB interface has a strong interfacial perpendicular magnetic anisotropy, when the CoFeB is 2.5nm, the interfacial perpendicular magnetic anisotropy is still sufficient to overcome the demagnetization field, so that the ...

Embodiment 2

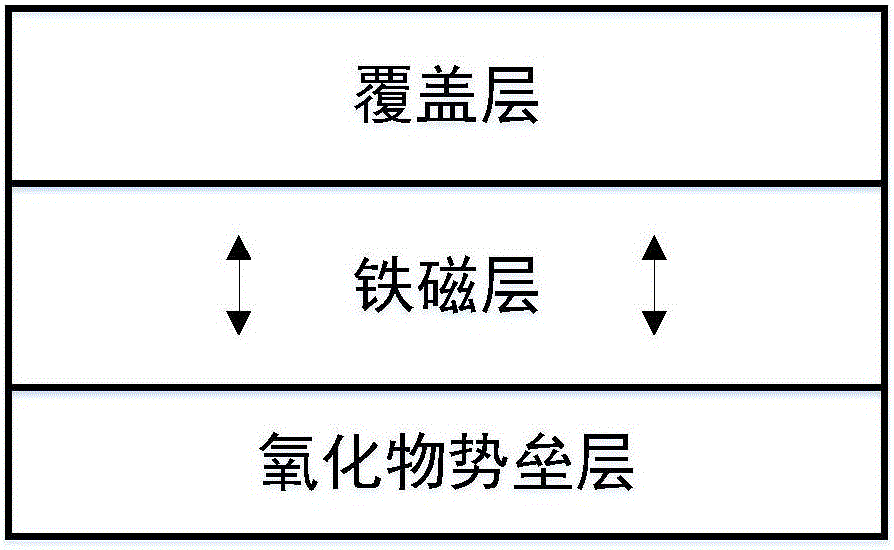

[0062] This embodiment is a specific example of the second solution. In this embodiment, the oxide barrier layer, the ferromagnetic layer and the cover layer are deposited on the thermally oxidized silicon substrate in order from bottom to top by magnetron sputtering, and a protective layer is deposited on the cover layer. layer, such as Figure 5 shown. Finally, photolithography, etching and other processing are carried out, and the cross-sectional area is circular.

[0063] Among them, the oxide barrier layer material is MgO, the thickness is 1nm; the ferromagnetic layer material is Co 20 Fe 60 B 20 , the thickness is 2.5nm; the cover layer material is Bi, the thickness is 1nm; the protection layer material is Ta, the thickness is 5nm. Because the CoFeB / Bi interface has a strong interfacial perpendicular magnetic anisotropy, when the CoFeB is 2.5nm, the interfacial perpendicular magnetic anisotropy is still sufficient to overcome the demagnetization field, so that the d...

Embodiment 3

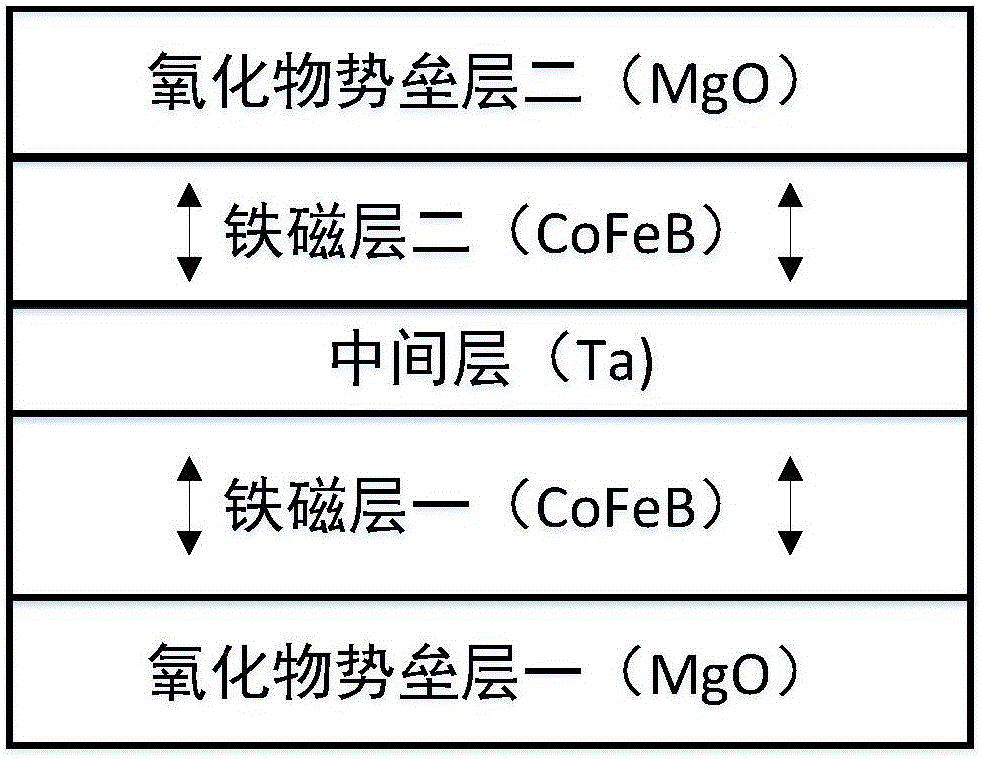

[0065] This embodiment is a specific example of the third solution. In this embodiment, oxide barrier layer 1, ferromagnetic layer 1, intermediate layer, ferromagnetic layer 2, and oxide barrier layer 2 are deposited on the thermal oxidation layer in order from bottom to top by magnetron sputtering. On the silicon substrate, and deposit a protective layer on the oxide barrier layer 2, such as Figure 6 shown. Finally, photolithography, etching and other processing are carried out, and the cross-sectional area is circular.

[0066] Among them, the material of the middle layer is Bi with a thickness of 0.4nm; the material of the ferromagnetic layer 1 is Co 20 Fe 60 B 20 , the thickness is 3nm; the material of ferromagnetic layer 2 is Co 20 Fe 60 B 20 , with a thickness of 1 nm; the oxide barrier layer 1 and the oxide barrier layer 2 are made of MgO with a thickness of 1 nm; the protective layer is made of Ta with a thickness of 5 nm. This is a double-interface structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com