Graphene oxide bonding capillary electrochromatography monolithic column and preparing method thereof

A technology of capillary electrochromatography and graphene, which is applied in the field of graphene oxide-bonded capillary electrochromatography monolithic columns and its preparation, can solve the problems of difficult control of conditions and many reaction steps, and achieve controllable reaction conditions, fewer steps, The effect of simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of Graphene Oxide Bonded Capillary Electrochromatographic Monolithic Column

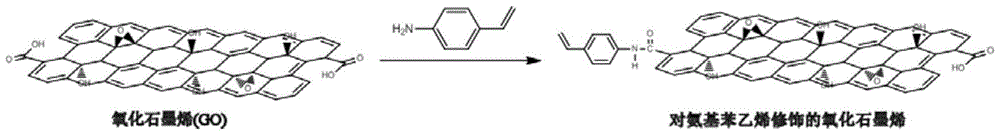

[0030] (1) Weigh 20 mg of graphene oxide (GO) into a test tube, add 50 mL of N,N-dimethylformamide (DMF), and treat with 25KHz ultrasonic for 2.5 hours to uniformly disperse the graphene oxide in DMF. Then add 200mg of p-aminostyrene (pAS) and 20mg of N,N'-dicyclohexylcarbodiimide (DCC) to the dispersion, put it in a 50℃ oil bath, protected from light, protected by argon, and stirred magnetically Reaction for 24h (reaction formula such as figure 1 ), and filtered to obtain 22 mg of solid product, which was recorded as pAS-GO.

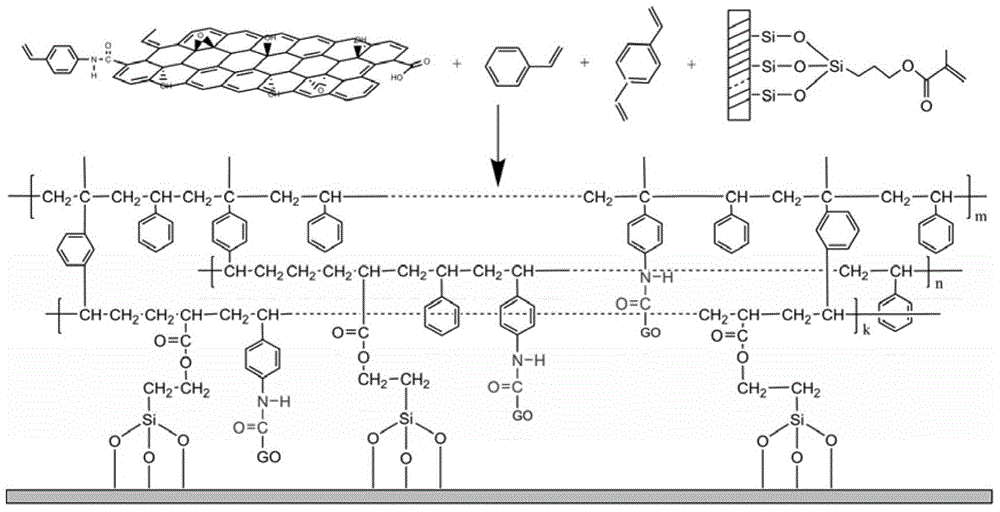

[0031] (2) Weigh 0.20 mg pAS-GO and add it to 450 μL cyclohexanol (432 mg), and sonicate at 25 KHz for 2.5 hours until the dispersion is uniform. Then add styrene (25μL, 22.73mg), DVB (50μL, 45.95mg), toluene (225μL, 194.85mg), AIBN (1.8mg) and AMPS (0.9mg), continue to disperse by 25KHz ultrasonic for 35min and then bubbling with nitrogen for 15min , Get the r...

Embodiment 2

[0033] Preparation of Graphene Oxide Bonded Capillary Electrochromatographic Monolithic Column

[0034] (1) Weigh 20 mg of graphene oxide (GO) into a test tube, add 50 mL of N,N-dimethylformamide (DMF), and treat with 25KHz ultrasonic for 2.5 hours to uniformly disperse the graphene oxide in DMF. Then add 200mg of p-aminostyrene (pAS) and 20mg of N,N'-dicyclohexylcarbodiimide (DCC) to the dispersion, put it in a 50℃ oil bath, protected from light, protected by argon, and stirred magnetically Reaction for 24h (reaction formula such as figure 1 ), and filtered to obtain 22 mg of solid product, which was recorded as pAS-GO.

[0035] (2) Weigh 0.2 mg of pAS-GO and add it to 400 μL of cyclohexanol (384 mg), and sonicate at 25KHz for 2.5 hours until the dispersion is uniform. Then add styrene (50μL, 45.45mg), DVB (100μL, 91.9mg), toluene (200μL, 173.2mg), AIBN (2mg) and AMPS (1mg), continue to disperse by 25KHz ultrasonic for 35min and then bubbling in nitrogen for 15min to obtain Reac...

Embodiment 3

[0037] Preparation of Graphene Oxide Bonded Capillary Electrochromatographic Monolithic Column

[0038] (1) Weigh 20 mg of graphene oxide (GO) into a test tube, add 50 mL of N,N-dimethylformamide (DMF), and treat with 25KHz ultrasonic for 2.5 hours to uniformly disperse the graphene oxide in DMF. Then add 200mg of p-aminostyrene (pAS) and 20mg of N,N'-dicyclohexylcarbodiimide (DCC) to the dispersion, put it in a 50℃ oil bath, protected from light, protected by argon, and stirred magnetically Reaction for 24h (reaction formula such as figure 1 ), and filtered to obtain 22 mg of solid product, which was recorded as pAS-GO.

[0039] (2) Weigh 0.20 mg pAS-GO and add it to 300 μL cyclohexanol (288 mg), sonicate at 25 KHz for 2.5 h until the dispersion is uniform. Then add styrene (100μL, 90.9mg), DVB (200μL, 183.8mg), toluene (150μL, 129.9mg), AIBN (2.2mg) and AMPS (1.1mg), continue to disperse by 25KHz ultrasonic for 35min and then bubbling with nitrogen for 15min , Get the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com