Catalyst for reforming CO2 and CH4 to synthesize gas and preparation method of catalyst

A catalyst and synthesis gas technology, applied in hydrogen/synthesis gas production, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of Ni loss of active components, reduction of active sites, loss of active components, etc. Achieve high conversion efficiency, high-efficiency catalytic reaction, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

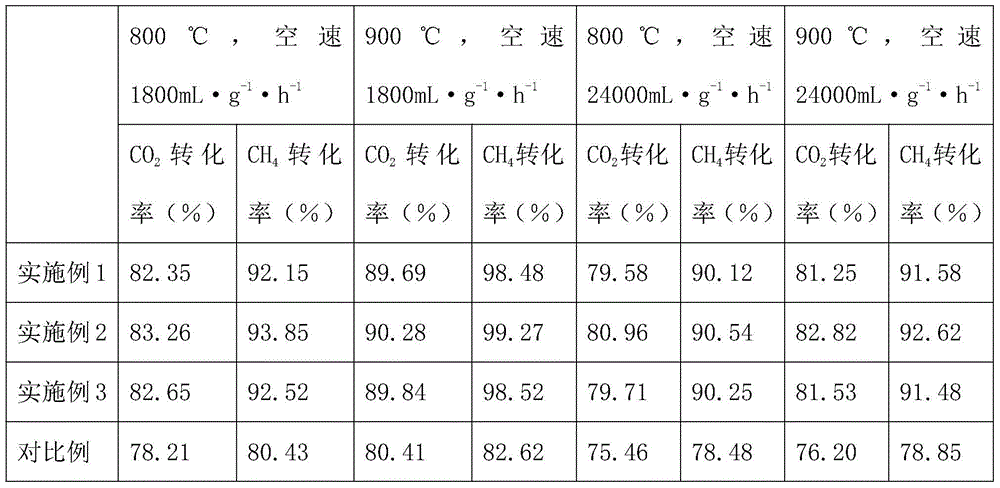

Examples

Embodiment 1

[0022] for CO 2 and CH 4 Catalyst for recombination into gas, consisting of the following mass fractions of raw materials: Ni / γ-Al 2 o 3 27%, Ni / MgO23%, Ce / ZrO 2 18%, carbon component 32%.

[0023] above for CO 2 and CH 4 The preparation steps of the catalyst for reforming into gas are as follows:

[0024] (1) Nickel nitrate is stirred and dispersed in methanol according to a solid-to-liquid ratio of 1:5, and is made into a nickel nitrate dispersion liquid with a concentration of 4mol / L; cerium sulfate is stirred and dispersed in methanol according to a solid-to-liquid ratio of 1:5, Be made into the cerium sulfate dispersion liquid that concentration is 4mol / L;

[0025] (2) γ-Al pre-calcined at 600°C 2 o 3 As a carrier, add it to the nickel nitrate dispersion at a solid-to-liquid ratio of 1:10, stir continuously, and ultrasonically treat it at 50°C for 30 minutes. Dry for 24 hours to obtain a nickel-based catalyst precursor; bake at 850°C for 5 hours, and reduce it a...

Embodiment 2

[0031] for CO 2 and CH 4 Catalyst for recombination into gas, consisting of the following mass fractions of raw materials: Ni / γ-Al 2 o 3 31%, Ni / MgO21%, Ce / ZrO 2 19%, carbon component 29%.

[0032] above for CO 2 and CH 4 The preparation steps of the catalyst for reforming into gas are as follows:

[0033] (1) Stir and disperse nickel chloride in n-propanol according to a solid-to-liquid ratio of 1:6 to form a nickel chloride dispersion with a concentration of 5mol / L; stir cerium chloride according to a solid-to-liquid ratio of 1:6 Disperse in n-propanol to prepare a cerium chloride dispersion with a concentration of 5mol / L;

[0034] (2) γ-Al pre-calcined at 600°C 2 o 3 As a carrier, it was added to the nickel chloride dispersion according to the ratio of solid to liquid ratio of 1:11, continuously stirred, ultrasonically treated at 55°C for 35min, left at room temperature for 21h, filtered, and transferred to a vacuum dryer at 125°C Dry at 880°C for 22h to prepare nic...

Embodiment 3

[0040] for CO 2 and CH 4 Catalyst for recombination into gas, consisting of the following mass fractions of raw materials: Ni / γ-Al 2 o 3 35%, Ni / MgO19%, Ce / ZrO 2 20%, carbon component 26%.

[0041] above for CO 2 and CH 4 The preparation steps of the catalyst for reforming into gas are as follows:

[0042] (1) Nickel acetate is stirred and dispersed in acetone according to a solid-to-liquid ratio of 1:7 to form a nickel salt dispersion with a concentration of 6mol / L; cerium nitrate is stirred and dispersed in acetone according to a solid-to-liquid ratio of 1:7, Prepare a cerium nitrate dispersion with a concentration of 6mol / L;

[0043] (2) γ-Al pre-calcined at 600°C 2 o 3 As a carrier, add it to the nickel acetate dispersion at a solid-to-liquid ratio of 1:12, stir continuously, and ultrasonically treat it at 60°C for 40 minutes, let it stand at room temperature for 24 hours, filter it, and transfer it to a vacuum desiccator at 128°C. Dry for 24 hours to prepare a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com