Zein and glycopolypeptide grafted copolymer and preparation method and application thereof

A zein and graft technology, which is applied in the field of chemical modification of natural protein and its medical application, can solve problems such as no research work, and achieves favorable cell growth, good biocompatibility and degradability. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

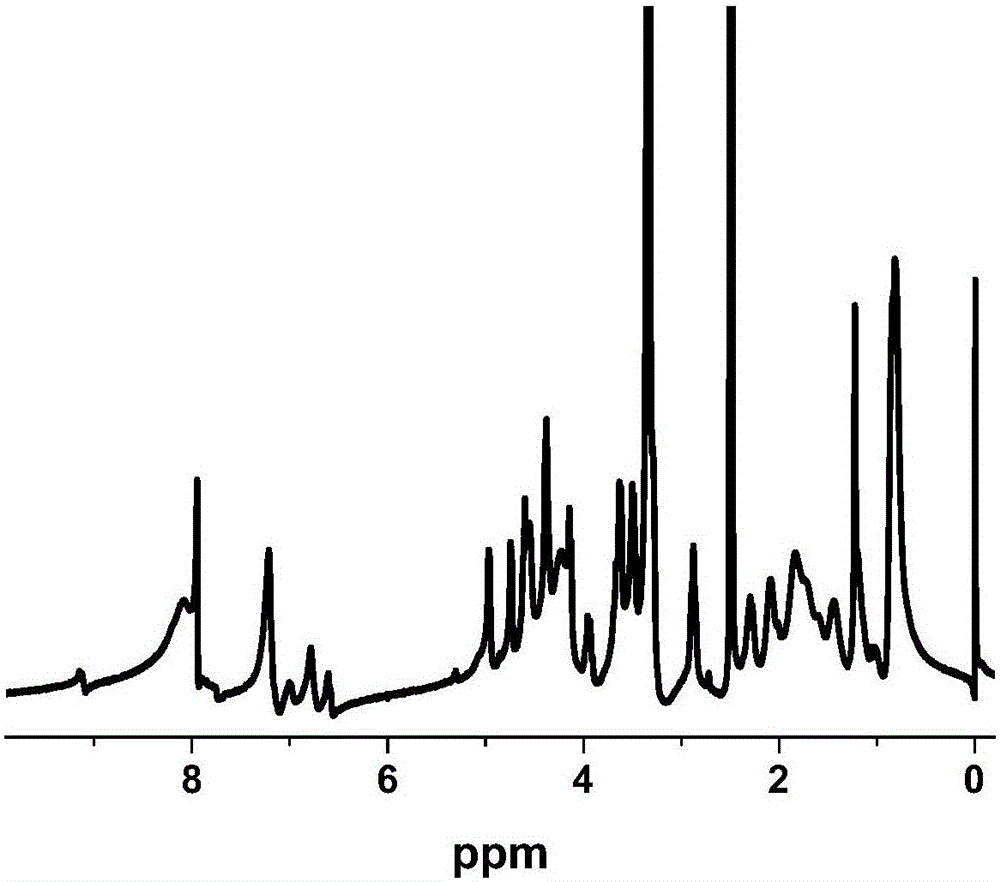

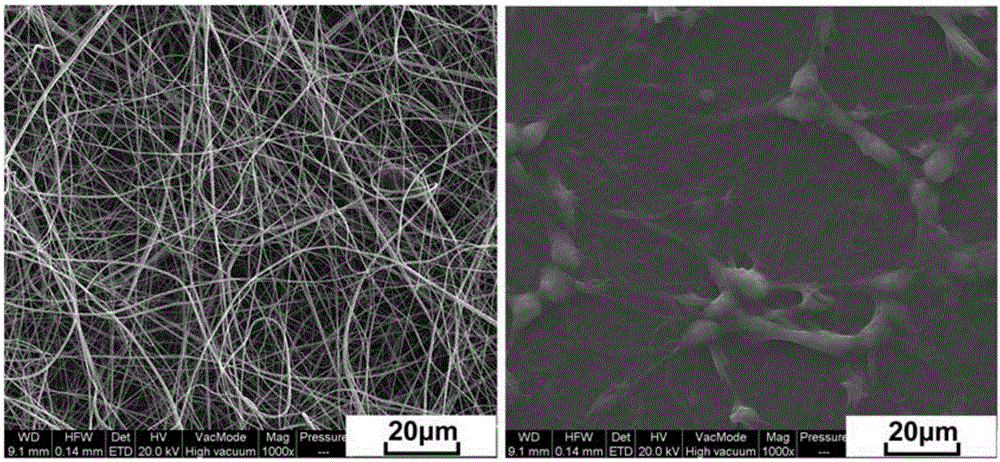

[0044] Example 1 Preparation of Zein and Glycopolypeptide Graft (ZG-1) and Electrospun Membrane

[0045] (1) Preparation of galactose pentaacetate

[0046] D-galactose (5.00 g) was dissolved in 15 mL of pyridine, and acetic anhydride (27 mL) was added at 0°C under nitrogen protection. After reacting for 24 hours, it was slowly poured into ice water (100 mL), and extracted three times with ethyl acetate. Use saturated NaHCO for the organic phase 3 The solution is cleaned until no gas is generated, and then washed with water and brine for 3 times. The organic phase was dried with anhydrous magnesium sulfate and then rotary evaporated to obtain an oily product with a yield of 97%.

[0047] (2) Preparation of 3-ynbutyl 2,3,4,6-tetra-O-acetyl-β-D-galactopyranoside

[0048] Dissolve galactose pentaacetate (10.00 g) and 3-butyn-1-ol (2.3 mL) in 50 mL of dry dichloromethane, add Et dropwise at 0°C under nitrogen protection 2 O·BF 3 (4.8mL), react at room temperature for 2h. Dilute with dic...

Embodiment 2

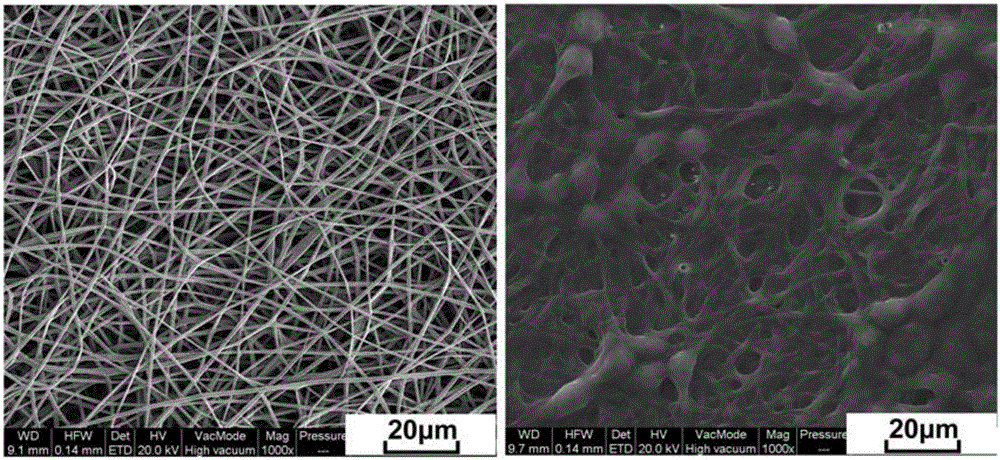

[0066] Example 2 Preparation of Zein and Glycopolypeptide Graft (ZG-2) and its Electrospun Membrane

[0067] (1) Preparation of galactose pentaacetate

[0068] D-galactose (5.00 g) was dissolved in 15 mL of pyridine, and acetic anhydride (27 mL) was added at 0°C under nitrogen protection. After reacting for 24 hours, it was slowly poured into ice water (100 mL), and extracted three times with ethyl acetate. Use saturated NaHCO for the organic phase 3 The solution is cleaned until no gas is generated, and then washed with water and brine for 3 times. The organic phase was dried with anhydrous magnesium sulfate and then rotary evaporated to obtain an oily product with a yield of 97%.

[0069] (2) Preparation of 3-ynbutyl 2,3,4,6-tetra-O-acetyl-β-D-galactopyranoside

[0070] Dissolve galactose pentaacetate (10.00 g) and 3-butyn-1-ol (2.3 mL) in 50 mL of dry dichloromethane, add Et dropwise at 0°C under nitrogen protection 2 O·BF 3 (4.8mL), react at room temperature for 2h. Dilute with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com