A kind of preparation method of titanium dioxide photocatalytic adsorption material

An adsorption material, titanium dioxide technology, applied in the field of photocatalytic composite adsorption materials, can solve the problems of photocatalytic technology such as low photon efficiency, difficulty in immobilizing catalysts, and improvement in catalytic efficiency, so as to improve photocatalytic efficiency, suppress electrons and space hole recombination, and the effect of improving photocatalytic oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

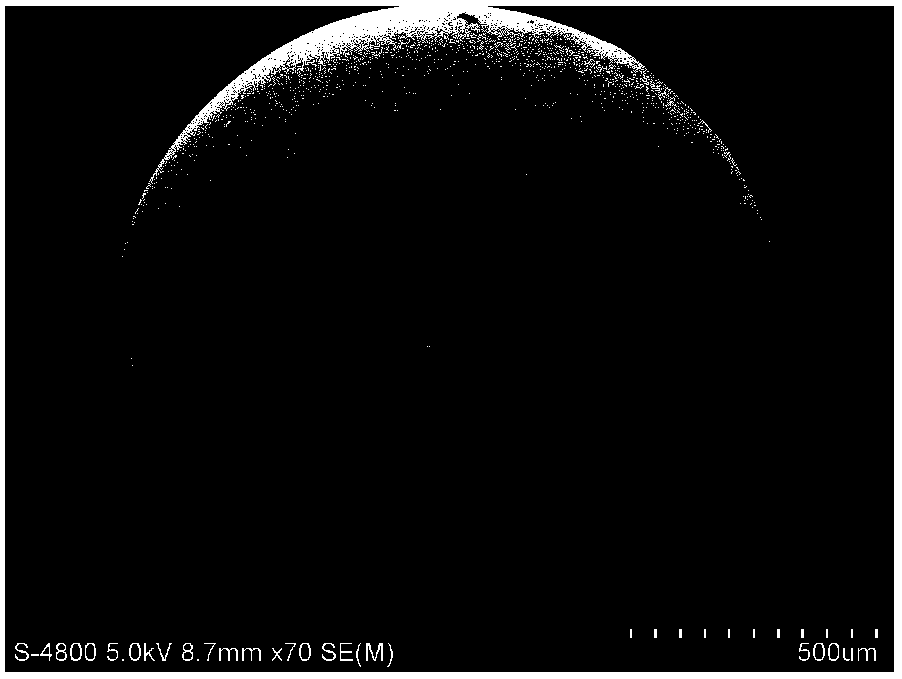

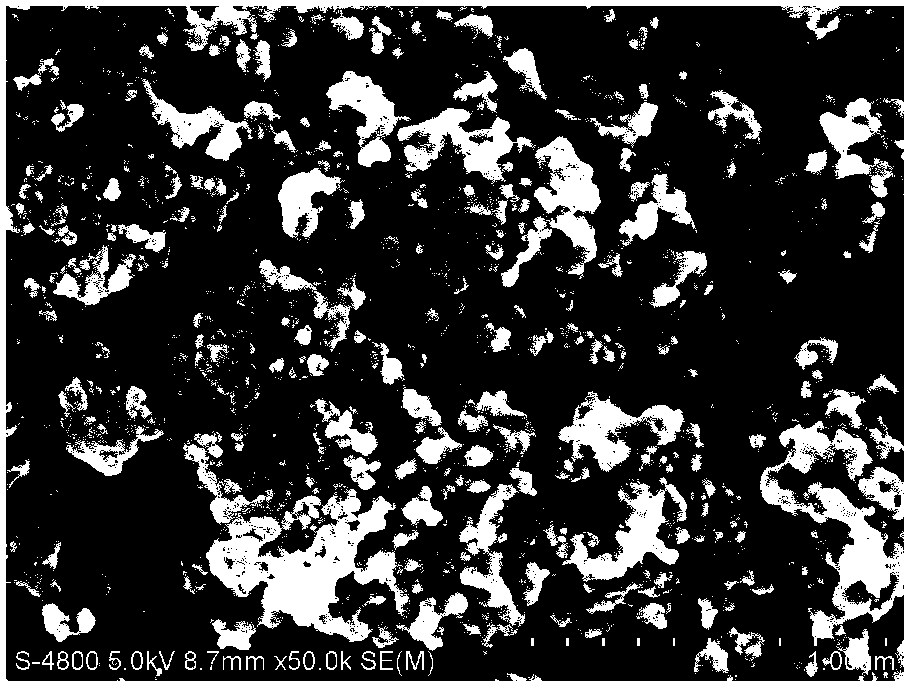

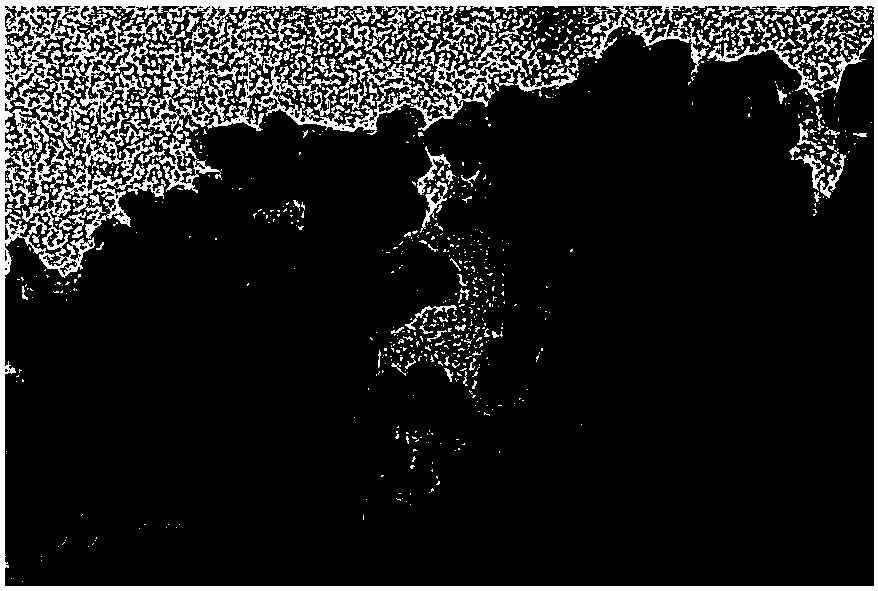

Image

Examples

Embodiment 1

[0031] The preparation method of titanium dioxide photocatalytic adsorption material of the present invention specifically comprises the following steps:

[0032] Step 1, add 8gTiO 2 Add 300mL distilled water and use 70W ultrasound for 60min to obtain suspension solution A;

[0033] Step 2, add TiO to suspension solution A 2 Mass 0.5% (0.04g) of silver nitrate and 0.005g of citric acid, after stirring for 60min, treated with ultraviolet light (12W, wavelength 254nm) for 120min to obtain mixed suspension solution B;

[0034] Step 3, add 3mL hydrochloric acid and 8g chitosan to the suspension solution B, stir to make it mix uniformly to obtain milky solution C;

[0035] Step 4, using an automatic injector (injection rate is 20ml / h, the needle is 4cm from the liquid level of the sodium hydroxide solution, and the inner diameter of the needle is 0.7mm) drips the milky solution C into sodium hydroxide (0.3mol / L, solution liquid surface height is 15cm) solution, after standing ov...

Embodiment 2

[0037] The preparation method of titanium dioxide photocatalytic adsorption material of the present invention specifically comprises the following steps:

[0038] Step 1, 4gTiO 2 Add 250mL of distilled water and use 70W ultrasound for 90min to obtain suspension solution A;

[0039] Step 2, add TiO to suspension solution A 2 Mass 0.3% (0.012g) of silver nitrate and 0.003g of citric acid, after stirring for 45min, treated with ultraviolet light (16W, wavelength 254nm) for 150min to obtain mixed suspension solution B;

[0040] Step 3, add 3mL hydrochloric acid and 8g chitosan to the suspension solution B, stir to make it mix uniformly to obtain milky solution C;

[0041]Step 4, using an automatic injector (injection rate is 40ml / h, the height of the needle from the liquid level of the sodium hydroxide solution is 3cm, and the inner diameter of the needle is 0.5mm) to drip the milky solution C into sodium hydroxide (0.3mol / L, solution liquid surface height is 15cm) solution, af...

Embodiment 3

[0043] The preparation method of titanium dioxide photocatalytic adsorption material of the present invention specifically comprises the following steps:

[0044] Step 1, 4.5g TiO 2 Add 250mL distilled water and use 70W ultrasound for 120min to obtain suspension solution A;

[0045] Step 2, add TiO to suspension solution A 2 Mass of 0.6% (0.027g) silver nitrate and 0.006g citric acid, after stirring for 30min, treated with ultraviolet light (18W, wavelength 254nm) for 120min to obtain mixed suspension solution B;

[0046] Step 3, add 3mL hydrochloric acid and 9g chitosan to the suspension solution B, stir to make it mix uniformly to obtain milky solution C;

[0047] Step 4, using an automatic injector (injection rate is 50ml / h, the needle is 3cm away from the liquid level of the sodium hydroxide solution, and the inner diameter of the needle is 0.7mm) drips the milky solution C into sodium hydroxide (0.3mol / L, solution liquid surface height is 10cm) solution, after standing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com