Comprehensive utilization method for waste residues and waste liquor generated in catalytic cracking catalyst production

A catalytic cracking and catalyst technology, which is applied in the direction of physical/chemical process catalysts, catalyst carriers, molecular sieve catalysts, etc., can solve the problem of less research on the overall reuse of waste residue and wastewater, cracking catalyst cracking activity, hydrothermal stability, dry gas and coke yield Low-level problems, to achieve the effect of reducing the difficulty of exchange, improving anti-wear performance, and controlling screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

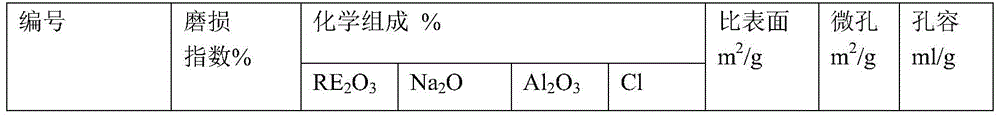

Examples

Embodiment 1

[0044] The waste residue produced by molecular sieve exchange, filtration and washing and the waste residue produced by gelation, washing and filtration of catalytic cracking catalyst were pressed with a plate and frame filter press for 30 minutes to form a filter cake, which was analyzed and burned for later use;

Embodiment 2

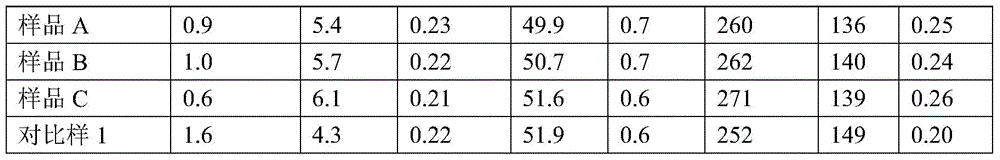

[0046] (1) Take 1200g of pressed filter cake and 4800g of molecular sieve secondary exchange zero-grade filtrate, mix and beat for preliminary exchange, add hydrochloric acid with a concentration of 6.4% to adjust the pH value to about 3.7, react for 20min, and take 4800g of catalyst washing waste liquid for rinsing , Wash with 3840g deionized water, filter the obtained material into a ball mill, add 1500g deionized water to grind for 2h, analyze the solid content and wait for gelation.

[0047] (2) Weigh 2250g of the slurry modified by the above method, mix it with 1286g REUSY and 279g deionized water for beating for 3h, add 580g of pseudoboehmite and stir vigorously for 30min, add 15wt% hydrochloric acid to the colloid for acidification and peptization for 15min, and continue stirring The catalyst is prepared by spray drying after uniformity.

[0048] (3) 600 g of the obtained catalyst was calcined in a muffle furnace at 430° C. for 1.5 h, and after the end, the sample was t...

Embodiment 3

[0051] (1) Take 1200g of pressed filter cake and 5760g of molecular sieve secondary exchange zero-grade filtrate, mix and beat for preliminary exchange, add hydrochloric acid with a concentration of 6.4% to adjust the pH value to about 3.7, react for 20min, and take 4800g of catalyst washing waste liquid for rinsing , Wash with 3840g deionized water, filter the obtained material into a ball mill, add 1500g deionized water to grind for 2h, analyze the solid content and wait for gelation.

[0052] (2) Weigh 2344g of the slurry modified by the above method, mix it with 1286g REUSY and 300g deionized water for beating for 3h, add 464g of pseudo-boehmite and stir vigorously for 30min, add 15wt% hydrochloric acid to the colloid for acidification and peptization for 15min, and continue stirring The catalyst is prepared by spray drying after uniformity.

[0053] (3) 600 g of the obtained catalyst was calcined in a muffle furnace at 430° C. for 1.5 h, and after the end, the sample was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com