A kind of technology that utilizes fixed-bed reactor to produce propylene

A fixed bed reactor and reactor technology, applied in the field of propylene production, to achieve the effects of reducing the difficulty of heat exchange, increasing the yield of propylene, and high product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The ZSM-5 that chooses phosphorus-iron modification is catalyst A, and the ZSM-5 that lanthanum modifies is catalyst B, and preparation method is as follows:

[0037] The required raw materials are HZSM-5 molecular sieve (Si:Al=50), binder, phosphoric acid, ferric nitrate, lanthanum nitrate aqueous solution, mix HZSM-5 molecular sieve and binder at a ratio of 3:1, and form it by extrusion Strip-shaped HZSM-5 molecular sieves were obtained by the impregnation method, and ZSM-5 molecular sieve catalysts containing 1.5% phosphorus and 1% iron were obtained by impregnation, and ZSM-5 catalysts containing 1.5% lanthanum were obtained. Additives can be added as appropriate during the preparation process.

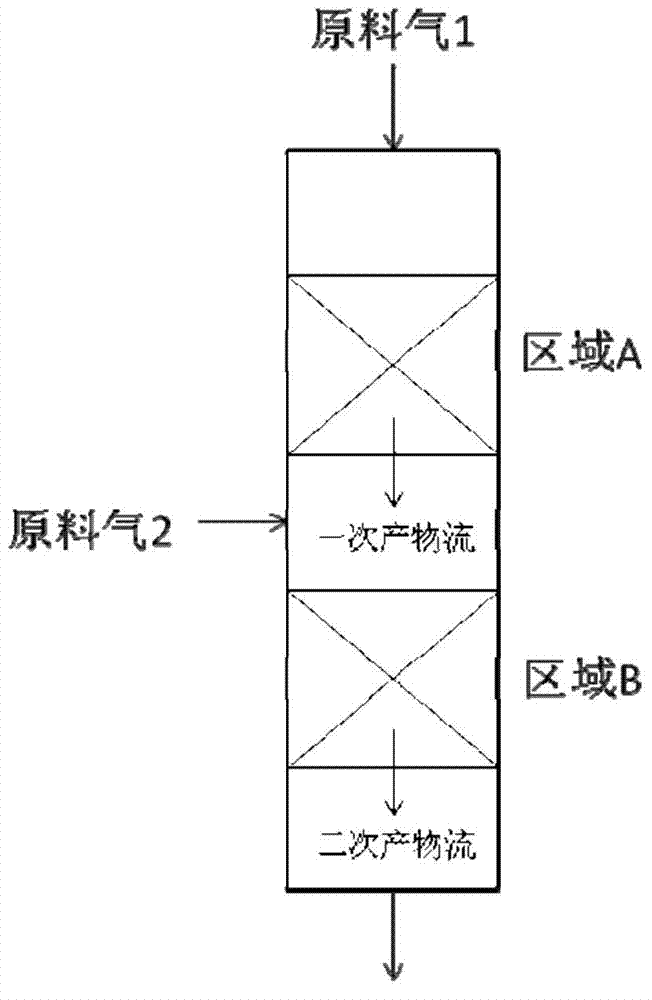

[0038] The bed temperature in area A of the fixed bed reactor is 430°C, the bed temperature in area B is 450°C, the pressure is 0.13Mpa, and the mass space velocity is 1.2h -1 . C 4 / C 5 The distillate is mixed with methanol and water vapor at a mass ratio of 2:3:12 for ...

Embodiment 2

[0041] Choose phosphorus-nickel modified ZSM-5 as catalyst A, phosphorus-lanthanum modified ZSM-5 as catalyst B, and the preparation method is as follows:

[0042] The required raw materials are HZSM-5 molecular sieve (Si:Al=50), binder, phosphoric acid, nickel nitrate, lanthanum nitrate aqueous solution, mix HZSM-5 molecular sieve and binder at a ratio of 3:1, and form by extrusion strip-shaped HZSM-5 molecular sieve obtained by the impregnation method, and the ZSM-5 molecular sieve catalyst containing 1.5% phosphorus and 1% nickel was obtained by the impregnation method, and the ZSM-5 catalyst containing 1.5% phosphorus and 1% lanthanum was obtained during the preparation process. Add additives.

[0043] The bed temperature in reactor area A is 440°C, the bed temperature in reactor area B is 460°C, the pressure is 0.16Mpa, and the mass space velocity is 1h -1 . C 4 / C 5 The distillate is mixed with methanol and water vapor in a mass ratio of 1:1:4 and then injected from ...

Embodiment 3

[0046] Choose phosphorus-nickel modified ZSM-5 as catalyst A, phosphorus-magnesium modified ZSM-5 as catalyst B, and the preparation method is as follows:

[0047] The required raw materials are HZSM-5 molecular sieve (Si:Al=50), binder, phosphoric acid, nickel nitrate, and magnesium nitrate aqueous solution. Mix HZSM-5 molecular sieve and binder in a ratio of 3:1, and form it by extrusion Strip-shaped HZSM-5 molecular sieves were obtained by the impregnation method, and ZSM-5 molecular sieve catalysts containing 1.5% phosphorus and 1% nickel were obtained by the impregnation method, and ZSM-5 catalysts containing 1.5% phosphorus and 2% magnesium were obtained during the preparation process. Add additives.

[0048] The bed temperature in reactor area A is 450°C, the bed temperature in reactor area B is 470°C, the pressure is 0.18Mpa, and the mass space velocity is 1.5h -1 . C 4 / C 5 The distillate is mixed with methanol and water vapor in a mass ratio of 1:2:8 and then inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com