M/MOx composite hydrogen resistance coating and preparation method thereof

A composite coating and hydrogen blocking technology, applied in coatings, chemical instruments and methods, metal material coating processes, etc., can solve the problems of high cost, complex preparation process, long time consumption, etc., to improve efficiency and simplify the preparation process. , The effect of improving the bonding force of the membrane substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

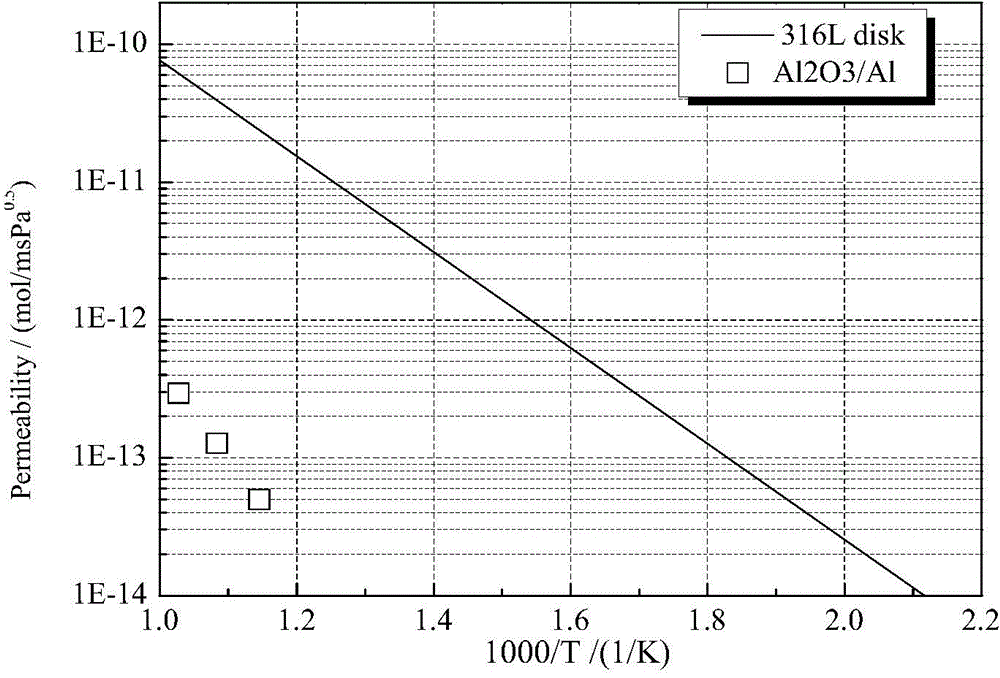

[0027] The transition layer and the hydrogen barrier coating were prepared using conventional sputtering equipment and reactive sputtering combined with negative bias technology.

[0028] 1) The 316L stainless steel substrate was ultrasonically cleaned with acetone and alcohol for 10 minutes respectively, and placed in a vacuum chamber.

[0029] 2) The back vacuum reaches 7×10 -3 After Pa, clean the substrate with a bias voltage, the negative bias voltage is -200V, the Ar pressure is 1Pa, and the cleaning time is 10min.

[0030] 3) The Al transition layer was prepared by DC reactive sputtering combined with negative bias technology, the sputtering current was 10A, the sputtering power was 3300W, the negative bias was -200V, the gas pressure was 1Pa, and the deposition was 15min.

[0031] 4) In situ preparation of Al on the Al transition layer by DC reactive sputtering combined with negative bias technology 2 o 3 Hydrogen barrier coating. Ar / O 2 The ratio is 10 / 1, the gas ...

Embodiment 2

[0034] The transition layer and the hydrogen barrier coating were prepared using conventional sputtering equipment and reactive sputtering combined with negative bias technology.

[0035] 1) The 304 stainless steel substrate was ultrasonically cleaned with acetone and alcohol for 10 minutes respectively, and placed in a vacuum chamber.

[0036] 2) The back vacuum reaches 5×10 -3 After Pa, clean the substrate with a bias voltage, the negative bias voltage is -50V, the Ar pressure is 2Pa, and the cleaning time is 20min.

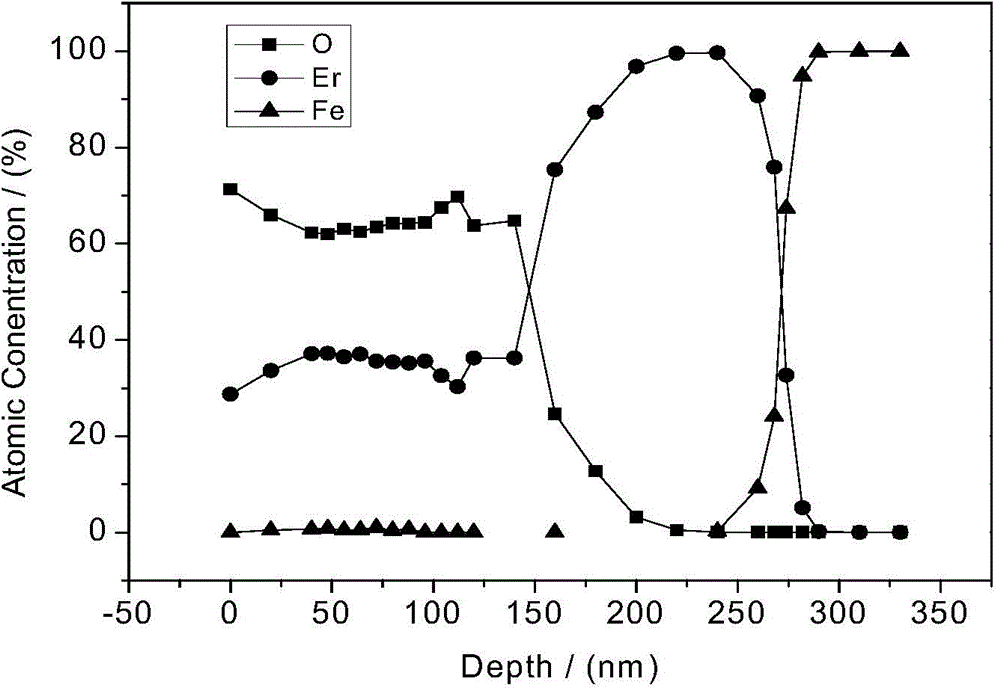

[0037] 3) The Er transition layer was prepared by radio frequency reactive sputtering combined with negative bias technology, the sputtering power was 1050W, the negative bias was -50V, the air pressure was 0.5Pa, and the deposition was 10min.

[0038] 4) In situ preparation of Er on the Er transition layer by radio frequency reactive sputtering combined with negative bias technology 2 o 3 Hydrogen barrier coating. Ar / O 2 The ratio is 10 / 3, the gas pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com