Preparation method of high-purity tubular conjugated microporous polymer carbonized high-purity carbon nanotube

A technology of conjugated micropores and carbon nanotubes, which is applied in the directions of carbon nanotubes, chemical instruments and methods, nanocarbons, etc., can solve the problems of clogging, uneven distribution of thickness, defects on the surface of the tube wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] According to the preparation method described above, its preparation steps are:

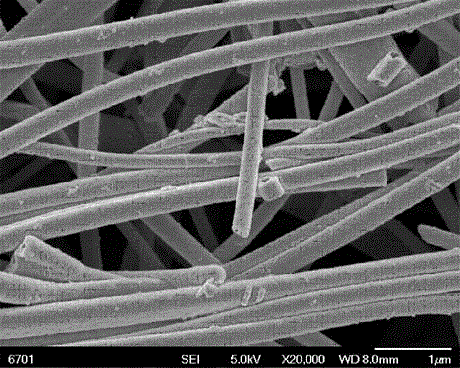

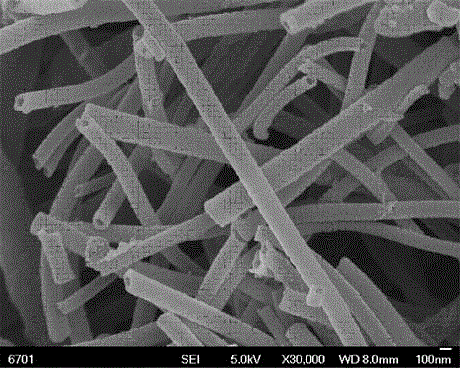

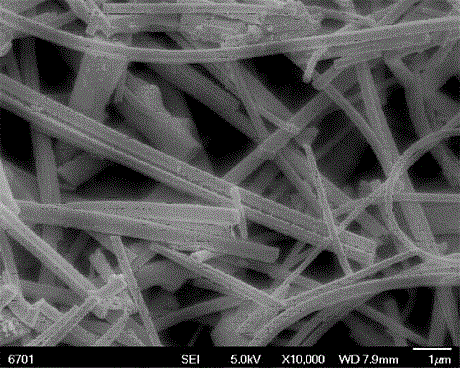

[0011] (1) Preparation of high-purity conjugated microporous polymer nanotubes: 1,3,5-triethynylbenzene and 2-amino-3,5 -Dibromopyridine is used as a monomer, with toluene and triethylamine as the solvent Pd(0) and CuI as the catalyst, the ratio of ethynyl and bromine in the monomer is adjusted to 5:1, and it is prepared by polymerizing at 80°C for 72h High-purity conjugated microporous polymer nanotubes;

[0012] (2) Preparation of high-purity carbon nanotubes by carbonizing high-purity conjugated microporous polymer nanotubes: heating the precursor of high-purity conjugated microporous polymer nanotubes to 600 °C at a heating rate of 5 °C / min in an argon atmosphere ℃, or 700°C, or 1000°C, let it carbonize, keep warm for 3h after the temperature rise, after the temperature drops to room temperature, wash the carbonized sample with ethanol and distilled water, and dry at 80°C for 24h to o...

Embodiment 1

[0014] Example 1: Weigh 750.9mg 1,3,5-triethynylbenzene, 377.87mg 2-amino-3,5-dibromopyridine, 150mg tetrakis(triphenylphosphine) palladium and 50mg cuprous iodide, add to containing In a flask containing 7.5ml of toluene and 7.5ml of triethylamine, degas with nitrogen for 30min, then raise the temperature to 80°C and stir for 72h to obtain a yellow polymer. The polymer was filtered and washed several times successively with chloroform, acetone, water and methanol to remove unreacted monomers and catalyst residues; then using methanol as a solvent, the obtained polymer was extracted by Soxhlet for 72 hours to obtain a high-purity conjugated microporous polymer nanotubes. The prepared high-purity conjugated microporous polymer nanotubes were raised to different temperatures (600°C, 700°C, 1000°C) at a heating rate of 5°C / min for 3 hours to carbonize the conjugated microporous polymer nanotubes. Then cool to room temperature, wash and dry several times with absolute ethanol and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com