Preparation method of high-adhesive-force functionalized water-soluble acrylic resin protective adhesive

A water-soluble acrylic, strong adhesion technology, applied in the field of preparation of strong adhesion functionalized water-soluble acrylic resin protective adhesive, to achieve the effect of good brightness and folding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

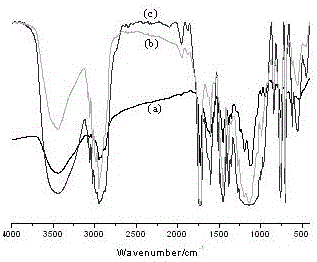

Image

Examples

Embodiment 1

[0029] Add 10 parts of n-pentanol directly to a 500ml four-necked flask equipped with an electric stirrer, a condenser and a thermometer, and heat up to 110°C with an electric heating mantle; 2 Under the conditions of protection, stirring, solvent condensation and reflux, the oil phase (the oil phase is 10 parts of styrene St, 5 parts of methyl methacrylate MMA, 5 parts of butyl acrylate BA, 3 parts of acrylic acid AA, methoxymethacrylate 0.1 part of methyl ethyl ester, 0.01 part of 1,4-butylene glycol dimethacrylate, 0.4 part of benzoyl peroxide) were added dropwise into the four-necked flask within 80 minutes; 0.15 parts of formyl, heat preservation reaction for 1 hour, then cool down to 60°C, add 2 parts of methylamine and 50 parts of ethanol. A functionalized acrylate emulsion with a solid content of 43% and an adhesion level of 3 can be obtained.

Embodiment 2

[0031] Add 20 parts of n-pentanol directly to a 500ml four-necked flask equipped with an electric stirrer, a condenser tube and a thermometer, and heat up to 110°C with an electric heating mantle; 2 Under the conditions of protection, stirring, solvent condensation and reflux, the oil phase (the oil phase is 20 parts of styrene St, 15 parts of methyl methacrylate MMA, 10 parts of butyl acrylate BA, 4 parts of acrylic acid AA, methoxymethacrylate 0.2 parts of methyl ethyl ester, 0.02 parts of 1,4-butanediol dimethacrylate, and 0.5 parts of benzoyl peroxide) were added dropwise into the four-necked flask within 100 minutes; 0.18 parts of formyl, heat preservation reaction for 1.2 hours, then cool down to 55°C, add 3 parts of methylamine and 40 parts of ethanol. A functionalized acrylate emulsion with a solid content of 43% and an adhesion level of 5 can be obtained.

Embodiment 3

[0033] Add 30 parts of n-pentanol directly to a 500ml four-necked flask equipped with an electric stirrer, a condenser and a thermometer, and heat up to 110°C with an electric heating mantle; 2Under the conditions of protection, stirring, solvent condensation and reflux, the oil phase (the oil phase is 25 parts of styrene St, 20 parts of methyl methacrylate MMA, 15 parts of butyl acrylate BA, 5 parts of acrylic acid AA, methoxymethacrylate 0.5 parts of methyl ethyl ester, 0.03 parts of 1,4-butylene glycol dimethacrylate, 0.6 parts of benzoyl peroxide) were added dropwise into the four-necked flask within 2 hours; 0.25 parts of formyl, heat preservation reaction for 1.5 hours, then cool down to 50°C, add 3.5 parts of methylamine and 30 parts of ethanol. A functionalized acrylate emulsion with a solid content of 43% and an adhesion level of 4 can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com