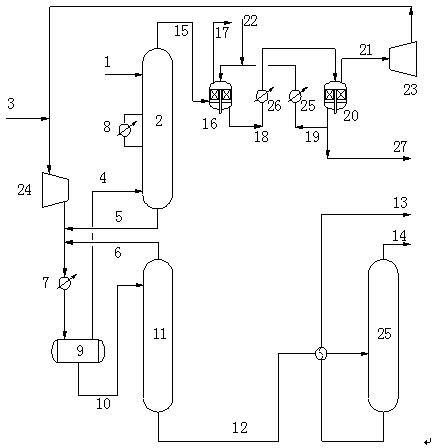

An energy-saving absorption stabilization process and system

A stable absorption and energy-saving technology, applied in gasoline stabilization, petroleum industry, processing of gas mixtures, etc., can solve problems such as economic losses, and achieve the effect of improving quality, improving absorption effect, and improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Taking the absorption stabilization system of a 500,000-ton / year catalytic cracking unit in China as an example, the ASPEN PLUS process simulation software is used to simulate the process of the present invention and the traditional process respectively:

[0033] The key process parameters of the process of the present invention are as follows: the outlet pressure of the compressor is 1.4 MPa, the operating temperature of the vapor-liquid separation tank is 35 °C, the liquid phase feed temperature of the desorption tower is 35 °C, the absorption tower is provided with an intermediate reboiler and the return tower temperature is 35 °C, the desorption The deoiled ethane content at the bottom of the tower is 0.1%w, the stable tower has a fixed reflux ratio of 2.2, the internal circulation of diesel oil is 20 t / h, the initial boiling point of regenerated diesel oil is 205°C, the feed rate of catalytic diesel oil is 13.2 t / h, and the vacuum degree of the desorption bed is 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com