Preparation method of boriding crystalline calcium sulfonate clearing agent

A technology of calcium sulfonate and detergent, which is applied in the direction of additives, petroleum industry, lubricating compositions, etc., can solve the problems of poor product stability, and achieve the effects of not easy to settle, good oil solubility and stability, and strong anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a boronated crystalline calcium sulfonate detergent, comprising the following steps in turn: mixing 100 parts by mass of an amorphous calcium sulfonate detergent with 10-60 parts by mass of base oil or a non-polar solvent, Stir at -70°C for 5-30 minutes, then sequentially add 20-100 parts by mass of polar solvent and 1-10 parts by mass of boron reagent, stir at 40-60°C for 5-30 minutes, then heat up to 70-120°C for reaction 0.5-5 hours, after the end, continue to heat up to 120-200°C to distill off the solvent to obtain boride crystalline calcium sulfonate detergent.

[0031] Wherein, the amorphous calcium sulfonate detergent comprises amorphous calcium carbonate, surfactant and base oil, the calcium content is 2-20wt%, the base number is 50-500mgKOH / g, and the average particle diameter of calcium carbonate nano-core is 10-200nm.

[0032] Wherein, the amorphous calcium sulfonate detergent comprises amorphous calcium carbonate, surfactant and bas...

Embodiment 1

[0044] In a 1L three-necked flask equipped with a mechanical stirrer and a reflux condenser, add calcium sulfonate detergent (TBN400mgKOH / g, 400g) and 150N base oil (200g), heat up to 50-60°C and stir for 10 minutes, then add methanol -Water (150ml-150ml) and boric acid (10g), continue to stir for 15 minutes, raise the temperature to 70-75°C for 2 hours, and then heat up to 150°C to evaporate the solvent to obtain a brown viscous product.

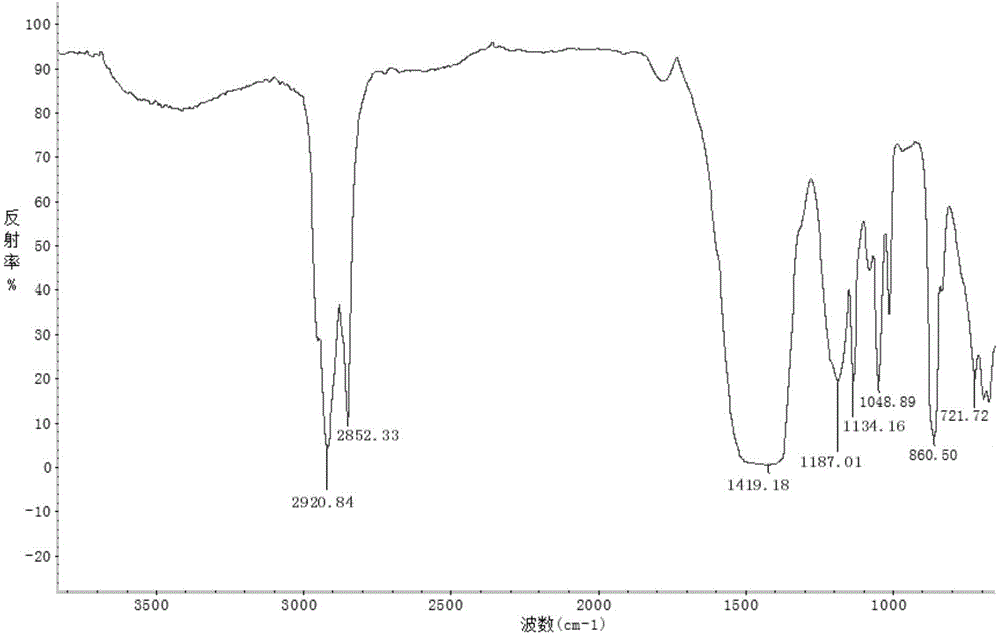

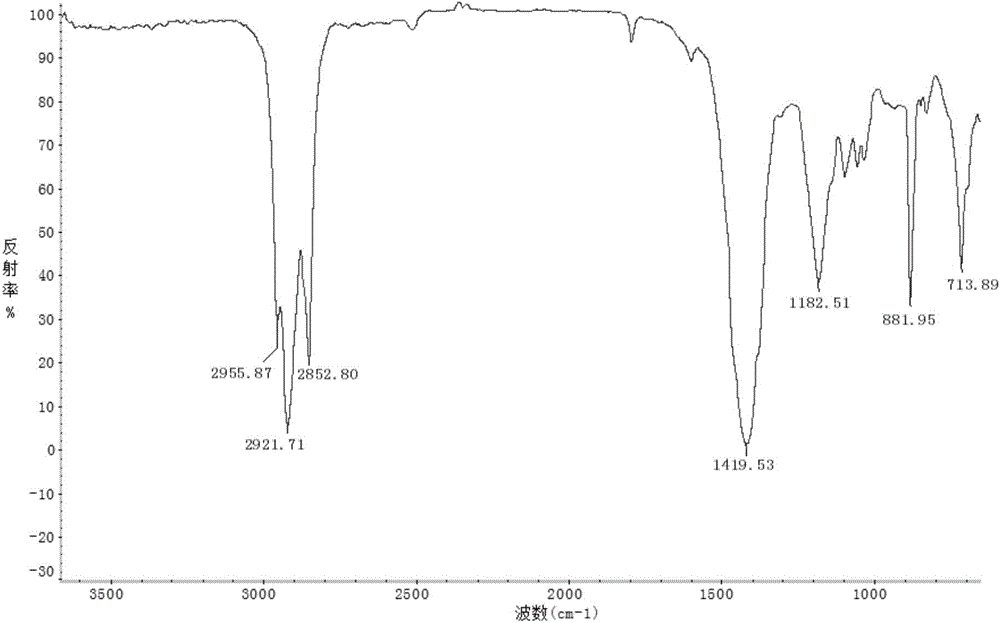

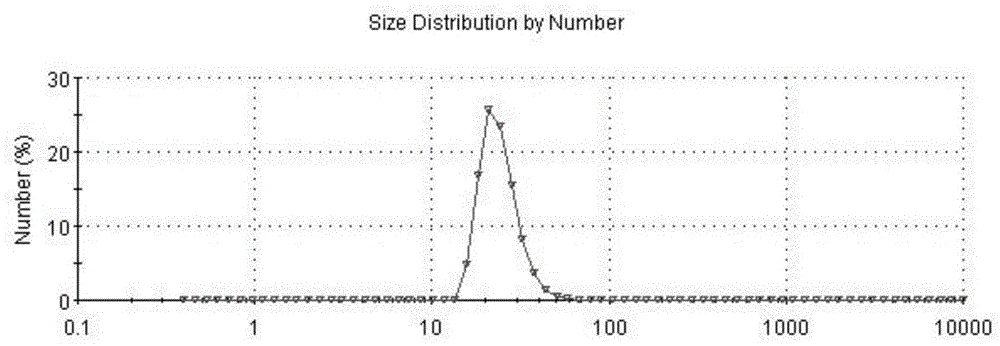

[0045] Infrared spectroscopy as a tool for qualitative and quantitative analysis of the crystal structure of calcium carbonate. Analyze raw material in embodiment 1 and IR spectrogram after conversion (see Figure 1a and Figure 1b ,in Figure 1a is the raw material IR diagram, Figure 1b It is the product IR picture) can be found: 722cm -1 and 860cm -1 The absorption peaks were shifted to 711cm -1 and 883cm -1 , 1400cm -1 The strong absorption peaks also become sharp, and these typical characteristic peak data indicate that the raw m...

Embodiment 2

[0048] In a 1L three-necked flask equipped with a mechanical stirrer and a reflux condenser, add calcium sulfonate detergent (TBN400mgKOH / g, 400g) and 100N base oil (150g), heat up to 50-60°C and stir for 10 minutes, then add methanol -Water (150ml-150ml) and boric acid (15g), continue to stir for 15 minutes, heat up to 70-75°C for 2 hours, after the end, heat up to 150°C to evaporate the solvent to obtain a brown viscous product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com