Preparation method of polydopamine/graphene oxide composite film with muramidase immobilized

A technology of graphene composite and polydopamine film, which is applied in the direction of fixation on or in the inorganic carrier, can solve the problems of short protein activity, affecting use, poor stability, etc., and achieve antibacterial time improvement, good immobilization, and antibacterial performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

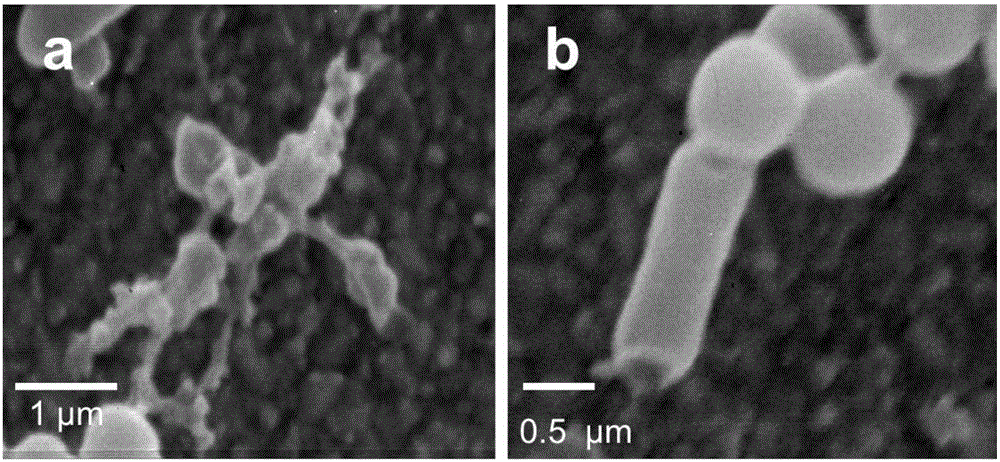

[0044] Example 1: The PDA / rGO-cLY film was modified with glass as the substrate.

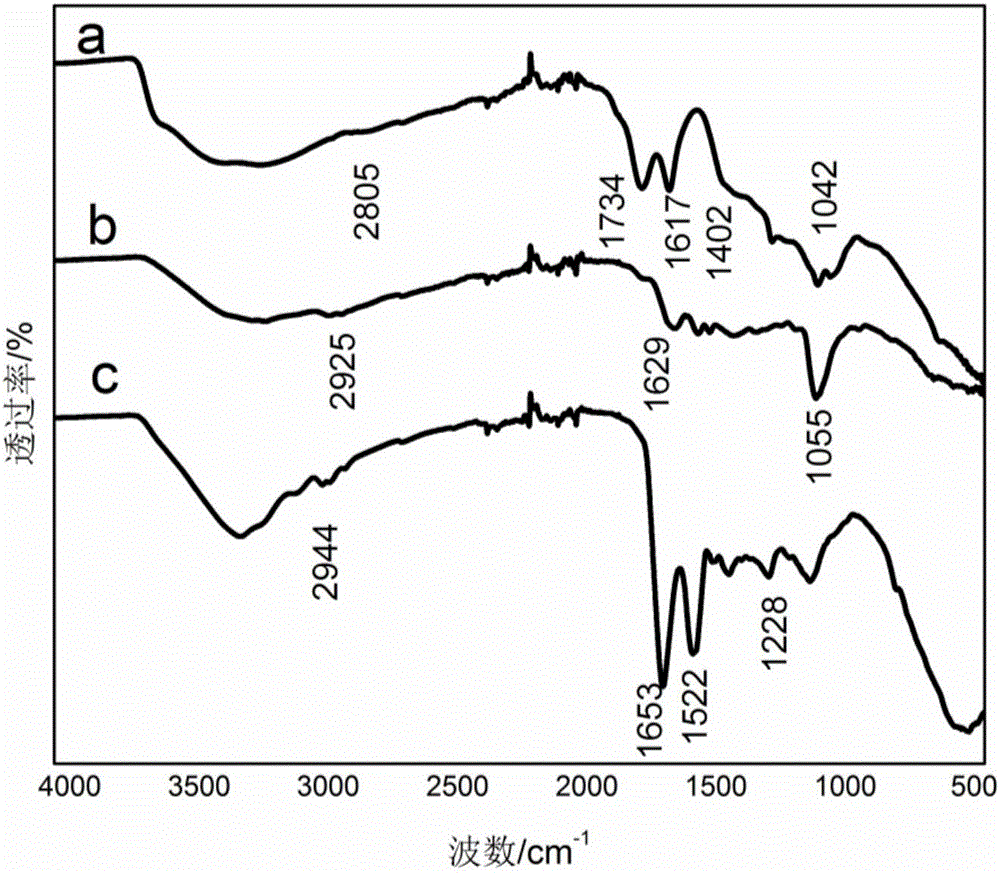

[0045]The reaction raw materials are dopamine hydrochloride, Tirs solution at pH 8.5, graphene oxide, egg white lysozyme, and PBS buffer at pH 7.4. Among them, dopamine hydrochloride was purchased from Sigma-Aldrich, egg white lysozyme was purchased from Sigma-Aldrich, the activity unit was ~100000U / mg, the molecular weight was a single chain of 14.3kDa, and the graphene oxide was obtained by the Hummers method (Marcano, D.C.; Kosynkin, D.V.; Berlin, J.M.; Sinitskii, A.; Sun, Z.; Slesarve, A.; Alemany, L.B.; Lu, W.; Tour, J.M. Improved Synthesis of Graphene Oxide.

[0046] (1) Dopamine modification of the glass surface

[0047] Dopamine was added to Tris solution at pH 8.5 to prepare 2 mg / mL, put into the cleaned glass slide, let stand at room temperature for 24 hours, take it out, ultrasonically clean it, and dry it with nitrogen gas.

[0048] (2) Preparation of incomplete graphene derivati...

Embodiment 2

[0070] Example 2: The glass surface was modified with PDA / rGO-cLY film.

[0071] The reaction raw materials are dopamine hydrochloride, Tirs solution with pH 8.5, egg white lysozyme, and PBS buffer solution with pH 7.4. Among them, dopamine hydrochloride was purchased from Sigma-Aldrich, egg white lysozyme was purchased from Sigma-Aldrich, the activity unit was ~100000U / mg, and the molecular weight was a single chain of 14.3kDa. Graphene oxide was prepared by the Hummers method. Fluorescein isothiocyanate (FITC) was purchased from Sigma-Aldrich.

[0072] Lysozyme was labeled with fluorescein isothiocyanate (FITC). Prepare 100 mL of a round solution of carbonate and sodium chloride with a pH of 9, add 1 g of lysozyme, disperse and dissolve, and lower the temperature to 4°C. Add 10 mg FITC to the lysozyme solution at 4°C, and magnetically stir in an ice-water bath for 12 hours in the dark to generate fluorescently labeled protein FITC-cLY. Prepare excess half-saturated amm...

Embodiment 3-5

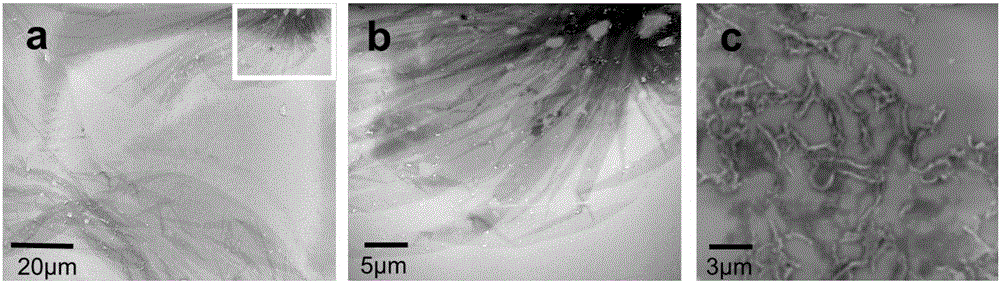

[0080] Embodiment 3-5: The PDA / rGO film layer was prepared on the glass surface under different concentration conditions.

[0081] The reaction raw materials are dopamine hydrochloride, Tirs solution with pH 8.5, and graphene oxide. Among them, dopamine hydrochloride was purchased from Sigma-Aldrich, and graphene oxide was obtained by Hummers method.

[0082] (1) Dopamine modification of the glass surface

[0083] Dopamine was added to Tris solution at pH 8.5 to prepare 2 mg / mL, put into the cleaned glass slide, let stand at room temperature for 24 hours, take it out, ultrasonically clean it, and dry it with nitrogen gas.

[0084] (2) Preparation of incomplete graphene derivative film layer

[0085] Add the Tris solution at pH 8.5 to graphene oxide, prepare 0.1mg / mL, 0.3mg / mL and 0.5mg / mL graphene oxide solutions respectively, adjust the pH to 8.5, and put the dopamine-treated glass slide into In the graphene oxide solution, soak for 3 hours at 50°C, take it out, clean it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com