Method for extracting lithium from lithium-containing liquid waste generated in waste lithium-ion battery recycling process

A lithium-ion battery and waste liquid technology, applied in the field of lithium recovery, can solve the problems of single product purity, insufficient economic and environmental protection, loss of lithium resources, etc., to achieve maximum recycling, simplify subsequent processing procedures, and improve utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Lithium-containing waste liquid produced during the recycling of waste lithium-ion battery cathode materials is mainly Li-containing waste liquid. + 、Na + 、H + and SO 4 2- aqueous solution, the pH of the solution is 4-5, and the lithium ion concentration is 7g / L.

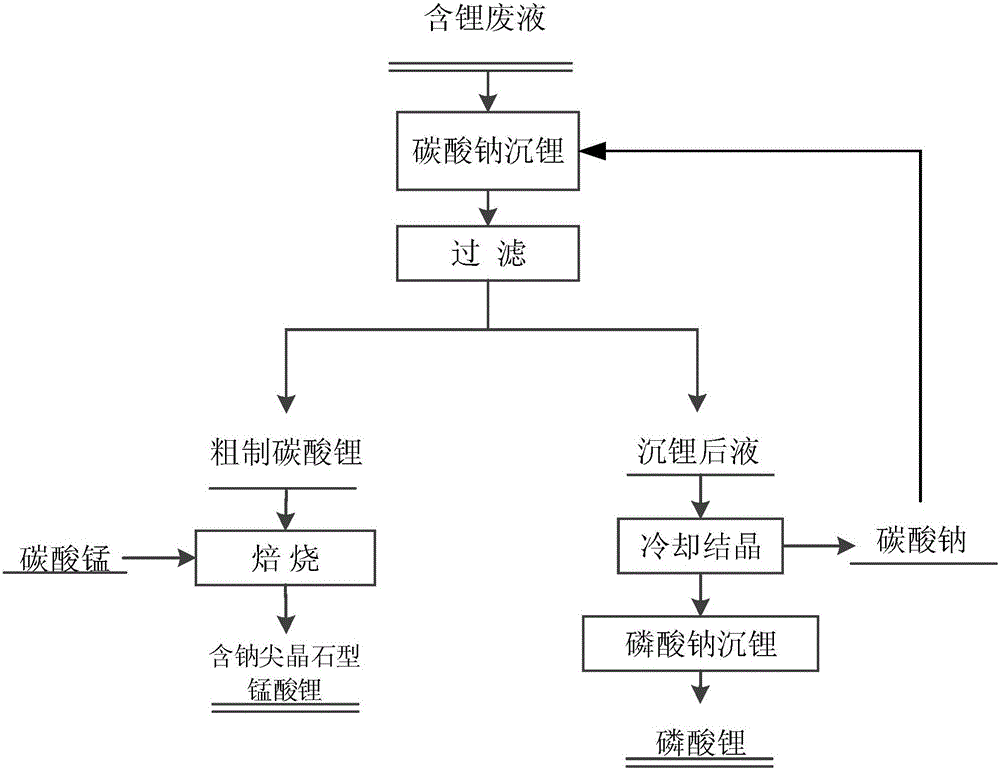

[0032] Such as figure 1 Shown, a kind of method of the present invention extracts lithium from the lithium-containing waste liquid that waste lithium ion battery recovery process produces, comprises the following steps:

[0033] (1) Sodium carbonate solid with theoretical solubility (maximum solubility in 100g of water at a certain temperature) is added to 200mL, 60°C lithium-containing waste liquid to carry out sodium carbonate lithium precipitation reaction, stirred for 1 hour, and then filtered and separated to obtain Liquid (filtrate) and crude lithium carbonate after sinking lithium;

[0034] (2) Cool and crystallize the lithium-precipitated liquid (filtrate) obtained in step (1) at 5° C., filter a...

Embodiment 2

[0039] Lithium-containing waste liquid produced during the recycling of waste lithium-ion battery cathode materials is mainly Li-containing waste liquid. + 、Na + 、H + and SO 4 2- aqueous solution, the pH of the solution is 4-5, and the lithium ion concentration is 7g / L.

[0040] Such as figure 1 Shown, a kind of method of the present invention extracts lithium from the lithium-containing waste liquid that waste lithium ion battery recovery process produces, comprises the following steps:

[0041] (1) Add 1.1 times the theoretical solubility of sodium carbonate solid into 200mL of lithium-containing waste liquid at 40°C to carry out the sodium carbonate lithium precipitation reaction, stir the reaction for 1 hour, and then filter and separate to obtain the lithium-precipitated liquid (filtrate) and crude lithium carbonate;

[0042] (2) Cool and crystallize the lithium-precipitated liquid (filtrate) obtained in step (1) at 8° C., filter and separate to obtain sodium carbon...

Embodiment 3

[0046] Lithium-containing waste liquid produced during the recycling of waste lithium-ion battery cathode materials is mainly Li-containing waste liquid. + 、Na + 、H + and SO 4 2- aqueous solution, the pH of the solution is 4-5, and the lithium ion concentration is 7g / L.

[0047] Such as figure 1 Shown, a kind of method of the present invention extracts lithium from the lithium-containing waste liquid that waste lithium ion battery recovery process produces, comprises the following steps:

[0048] (1) Add 1.05 times the theoretical solubility of sodium carbonate solid into 200mL of lithium-containing waste liquid at 70°C to carry out sodium carbonate lithium precipitation reaction, stir the reaction for 1 hour, and then filter and separate to obtain the lithium-precipitated liquid (filtrate) and crude lithium carbonate;

[0049] (2) Cool and crystallize the lithium-precipitated liquid (filtrate) obtained in step (1) at 10° C., filter and separate to obtain sodium carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com