Ultrasonic-assisted method for extracting total flavonoid in alfalfa

A technology for auxiliary extraction and total flavonoids, which is applied in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of long extraction time, reduce equipment use efficiency, increase energy consumption, etc., and improve the extraction yield. , The effect of improving purity and extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

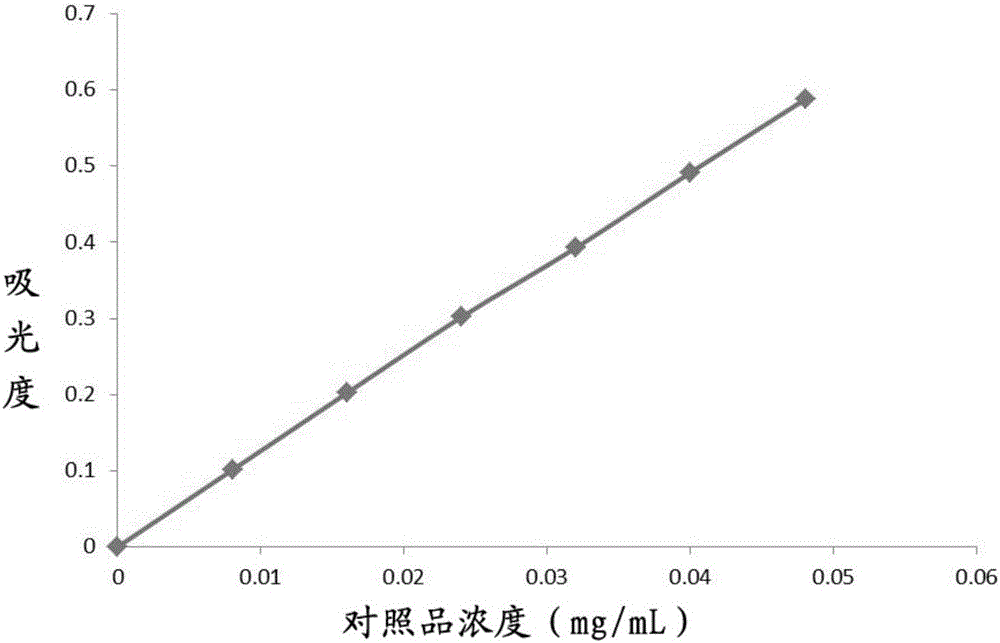

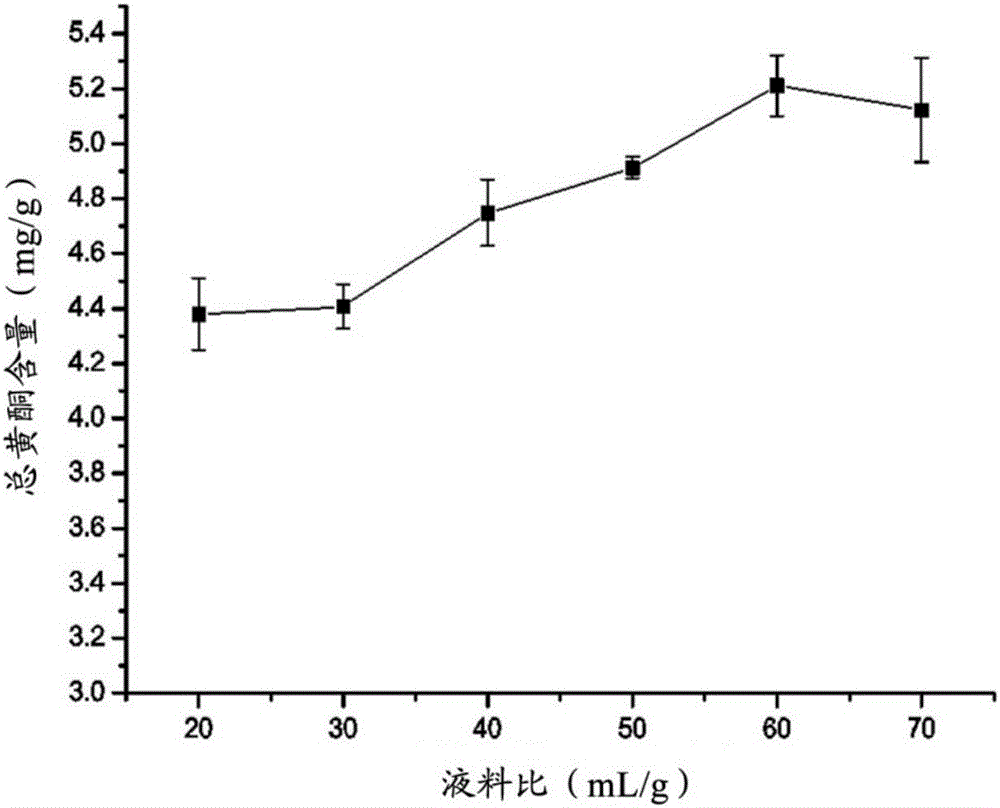

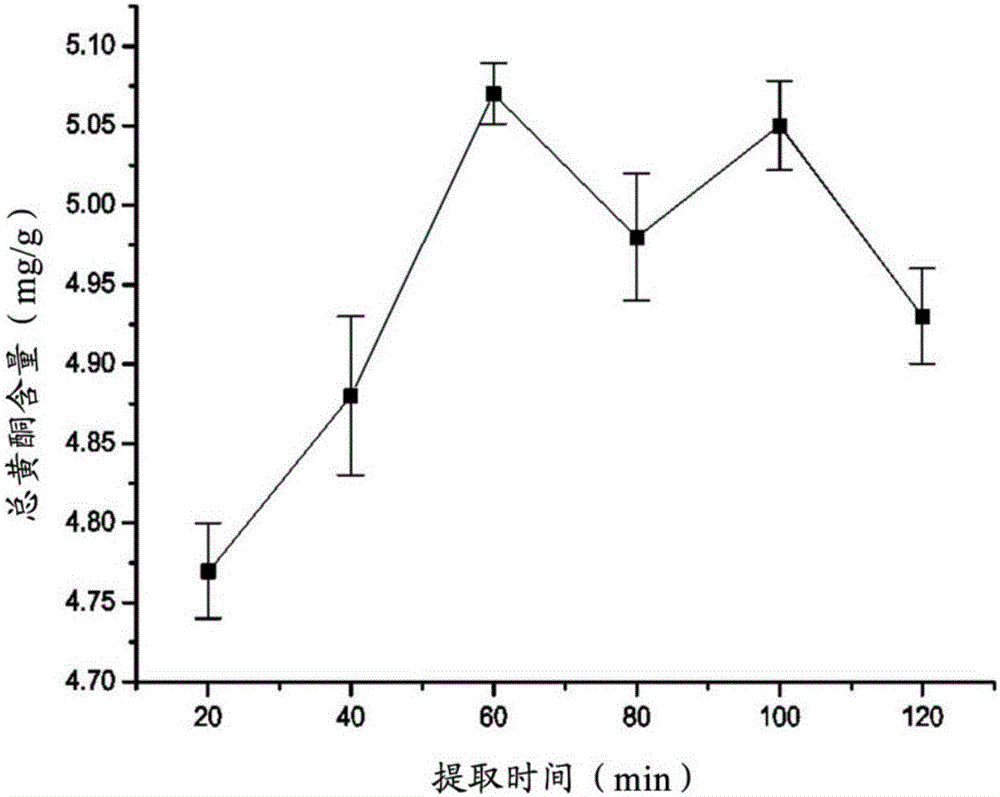

[0045] Ultrasonic-assisted extraction of total flavonoids from alfalfa and optimization of its condition parameters

[0046] 1. Preparation of Alfalfa Powder

[0047] The alfalfa was dried in a constant temperature drying oven at 65°C for 12 hours (the moisture content after drying was 4.74wt%), then put into a pulverizer for pulverization, and passed through a 60-mesh sieve for subsequent use. The sieved alfalfa powder was wrapped with filter paper, placed in a Soxhlet extractor, and then 15 times the volume (based on petroleum ether: sieved alfalfa powder = mL: g, the same below) of petroleum ether ( Boiling range 30-60°C), Soxhlet extraction for 24 hours to remove chlorophyll and lipids. Then the alfalfa powder was volatilized to dry petroleum ether and placed in a blast drying oven at 65° C. for 2 hours to dry (moisture content after drying was 4.7 wt %) to obtain the processed alfalfa powder.

[0048] 2. Extraction of total flavonoids from alfalfa

[0049] The ethanol ...

Embodiment 2

[0075] 1. Preparation of Alfalfa Powder

[0076] Alfalfa (aboveground part) was dried at 65°C for 12 hours in a blast drying oven (moisture content after drying was 4.25wt%), then put into a pulverizer to pulverize, and passed through a 60-mesh sieve (R40 in line with China's national standard). / 3 series) spare. Put the sieved alfalfa powder into the flask, then add 15 times the volume (mL:g) of petroleum ether (boiling range 30-60°C), and heat to reflux for 4 hours to remove chlorophyll and lipids. The mixture after the reflux is filtered, and the filter cake is washed with sherwood oil, and then the obtained alfalfa powder is evaporated to dryness of sherwood oil in a fume hood, and then placed in a blast drying oven at 65° C. for 2 hours (moisture content after drying is 4.12wt%), obtains the processed alfalfa powder.

[0077] 2. Extraction of total flavonoids from alfalfa

[0078] The ethanol solution that the volume fraction is 65% (v / v) is mixed with the alfalfa powd...

Embodiment 3

[0080] 1. Preparation of Alfalfa Powder

[0081] Alfalfa grass (aboveground part) was dried at 65°C for 12 hours in a blast drying oven (moisture content after drying was 4.18wt%), then put into a pulverizer to pulverize, and crossed a 60-mesh sieve (R40 in line with China's national standard). / 3 series) spare. Put the sieved alfalfa powder into a flask, then add 15 times the volume (mL:g) of petroleum ether (boiling range 30-60°C), and heat to reflux for 24 hours to remove chlorophyll and lipids. The mixture after the reflux is filtered, and the filter cake is washed with sherwood oil, and then the obtained alfalfa powder is evaporated to dryness of sherwood oil in a fume hood, and then placed in a blast drying oven at 65° C. for 2 hours (moisture content after drying is 4.20wt%), obtains the processed alfalfa powder.

[0082] 2. Extraction of total flavonoids from alfalfa

[0083]The ethanol solution that the volume fraction is 65% (v / v) is mixed with the alfalfa powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com