A multi-component extraction device for oilfield sludge and a method for recovering moisture in the dryer

An extraction device and technology for oilfield sludge, applied in chemical instruments and methods, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc., can solve problems such as inaccurate moisture content test of oily sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

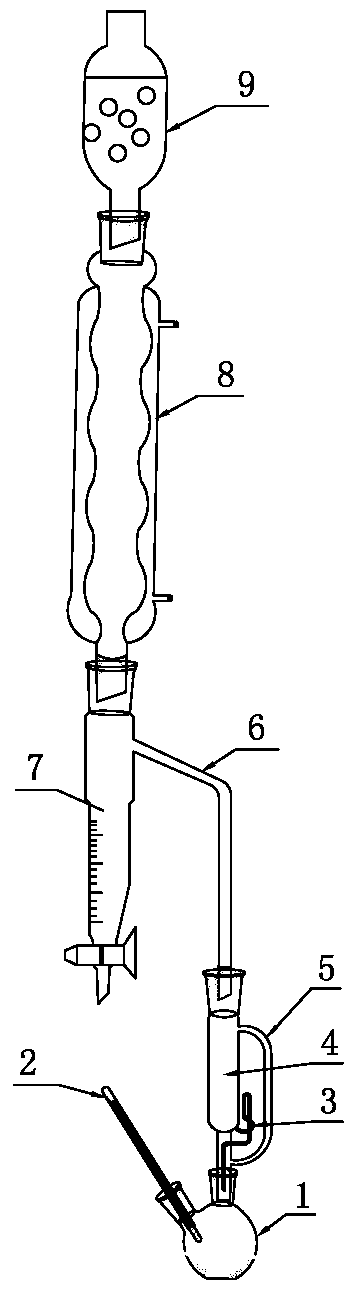

[0018] like figure 1 Shown is the oilfield sludge multi-component extraction device of the present invention, comprising an extraction bottle 1 containing an extraction solvent at the bottom, a heating device is provided below the extraction bottle 1, and a thermometer 2 is also provided in the extraction bottle 1 for To measure the heating temperature of the solvent, the top of the extraction bottle 1 is provided with an extraction tube 4 for holding the solute. The bottom of the extraction tube 4 is closed and the upper part is open. Capillary 3, a bypass pipe 5 is provided between the upper mouth of the extraction bottle 1 and the upper part of the extraction pipe 4. The bypass pipe 5 extends upward to the upper end of the extraction pipe 4 and communicates with it laterally. The water separator, the water separator includes the water dividing cylinder 7 on the lower side and the branch pipe 6 bypassing the water dividing cylinder 7 above, the outlet below the branch pipe 6...

Embodiment 2

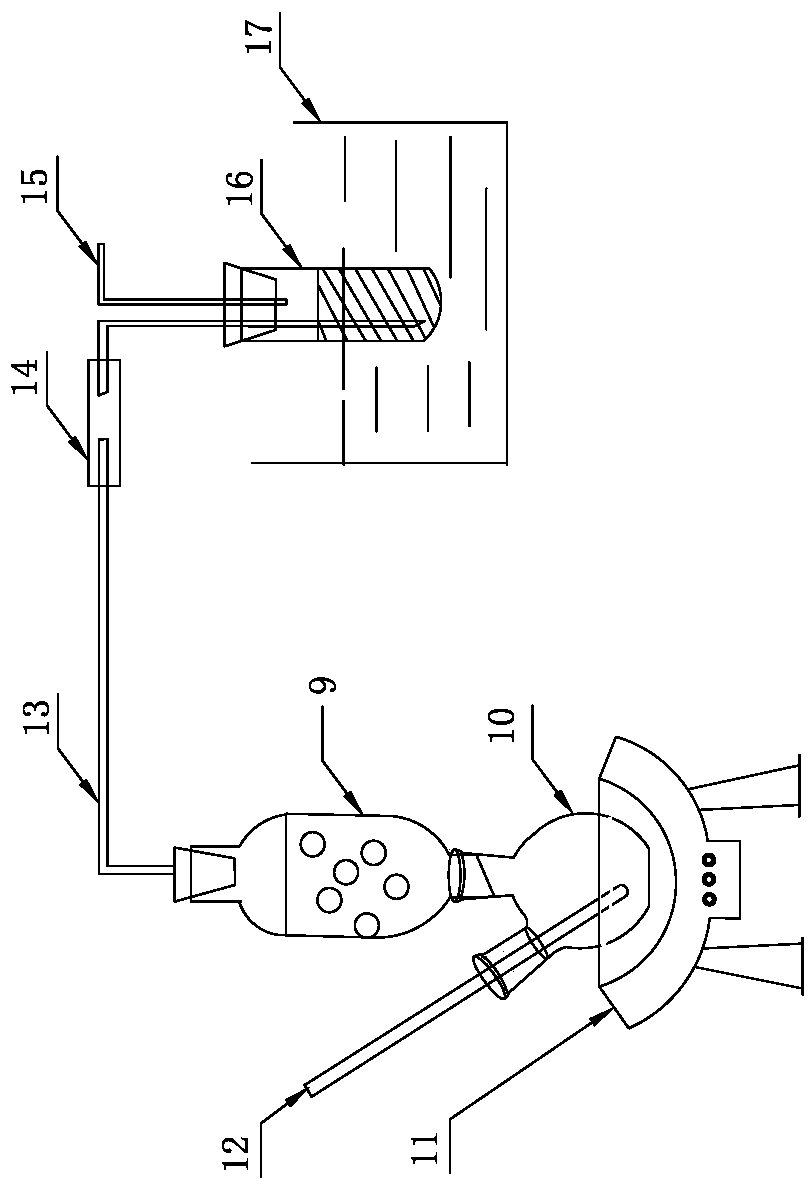

[0023] The method for recovering moisture in the drier in the oilfield sludge multi-component extraction device using the above-mentioned moisture recovery device, the specific process is: the bottom of the drier 9 after extraction and separation is connected to the first opening of the three-necked flask 10, and the drier The top of 9 is connected with the small test tube 16 that anhydrous calcium chloride is housed by air outlet pipe 13, elastic silica gel transition pipe 14, because anhydrous calcium chloride has very strong water absorption performance, in the inventive method, dry in drier 9 The consumption of agent is generally 40 ~ 60 grams, and the weight of calcium chloride in the small test tube 16 is 5 ~ 6 grams; Contain cooling liquid inside; connect the nitrogen gas input pipe 11, pass nitrogen gas into the three-necked flask 10 at 0.3 L / min, start the constant temperature heating device 11 at the same time, and adjust the heating temperature to 105~110° to heat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com