Anti-mildew putty powder and preparation method thereof

A putty powder and anti-mold technology, applied in the direction of filling slurry, etc., can solve the problems of poor adhesion and mildew resistance, poor washability of putty powder, unsightly shedding of putty powder, etc., to achieve good brushing effect, anti-corrosion Good folding strength, good adhesion and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

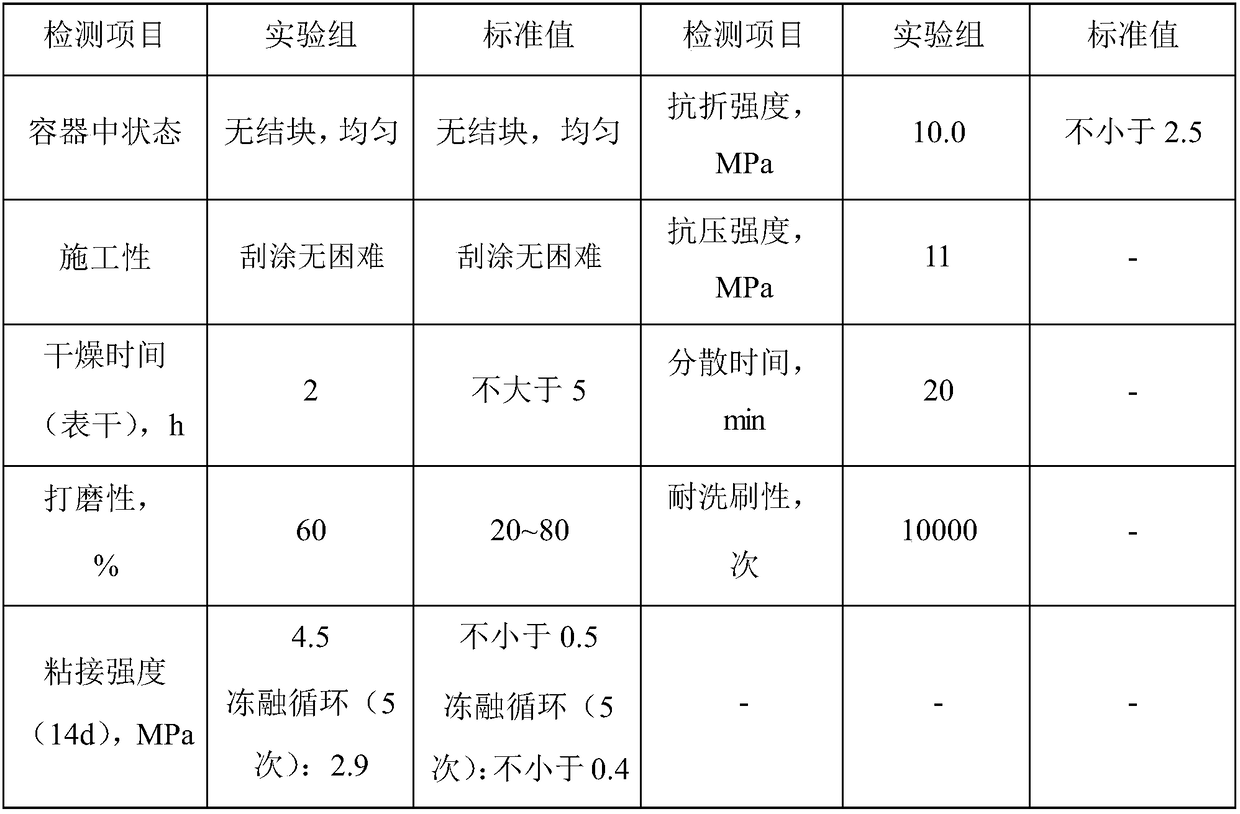

Examples

Embodiment 1

[0027] 1) Weigh component A, in parts by weight, said component A includes 20 parts of cellulose, 8 parts of starch glue and 0.2 part of antifungal agent, mix and stir for 10 minutes to obtain a mixture;

[0028] 2) Add component B to the mixture, in parts by weight, the component B includes 800 parts of 200 mesh talcum powder and 8 parts of bentonite, stir at a stirring speed of 1500 rpm for 8 minutes, and add while stirring 3 parts of nano-silica, after stirring, add 2 parts of squash gum, and continue stirring at a stirring speed of 1000 rpm for 3-8 minutes to obtain mildew-resistant putty powder.

[0029] Wherein, the antifungal agent includes the following raw materials in parts by weight: 5 parts of chitosan, 3 parts of polyquaternium salt, 2 parts of chloroacetamide, 5 parts of acetic acid, 1 part of allicin and 1 part of citric acid.

Embodiment 2

[0031] 1) Weigh component A, in parts by weight, said component A includes 30 parts of cellulose, 15 parts of starch glue and 1 part of antifungal agent, mix and stir for 10 minutes to obtain a mixture;

[0032] 2) Add component B to the mixture, in parts by weight, the component B includes 1200 parts of 200 mesh talcum powder and 12 parts of bentonite in the above parts by weight, and stir for 15 minutes at a stirring speed of 2000 rpm, Add 6 parts of nano-silica while stirring, add 5 parts of safflower gum after stirring, and continue stirring for 8 minutes at a stirring speed of 1500 rpm to obtain mildew-resistant putty powder.

[0033] Wherein, the antifungal agent includes the following raw materials in parts by weight: 10 parts of chitosan, 6 parts of polyquaternium salt, 5 parts of chloroacetamide, 10 parts of acetic acid, 2 parts of allicin and 2 parts of citric acid.

Embodiment 3

[0035] 1) Weigh component A, in parts by weight, said component A includes 25 parts of cellulose, 10 parts of starch glue and 0.5 part of antifungal agent, mix and stir for 10 minutes to obtain a mixture;

[0036] 2) Add B component to the mixture, in parts by weight, the B component includes 1000 parts of 200 mesh talcum powder and 10 parts of bentonite. Stir at a stirring speed of 1800 rpm for 10 minutes, and add nano 5 parts of silicon dioxide, after stirring, add 4 parts of squash gum, and continue stirring for 5 minutes at a stirring speed of 1200 rpm to obtain mildew-resistant putty powder.

[0037]Wherein, the antifungal agent includes the following raw materials in parts by weight: 8 parts of chitosan, 5 parts of polyquaternium salt, 3 parts of chloroacetamide, 7 parts of acetic acid, 1 part of allicin and 2 parts of citric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com