A method for treating zinc sulfide concentrate based on self-propagating reaction

A zinc sulfide concentrate and self-propagating technology, which is applied in the direction of improving process efficiency, can solve the problems of complex and lengthy process, high energy consumption, high cost, etc., and achieve the effect of simple process, low energy consumption and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

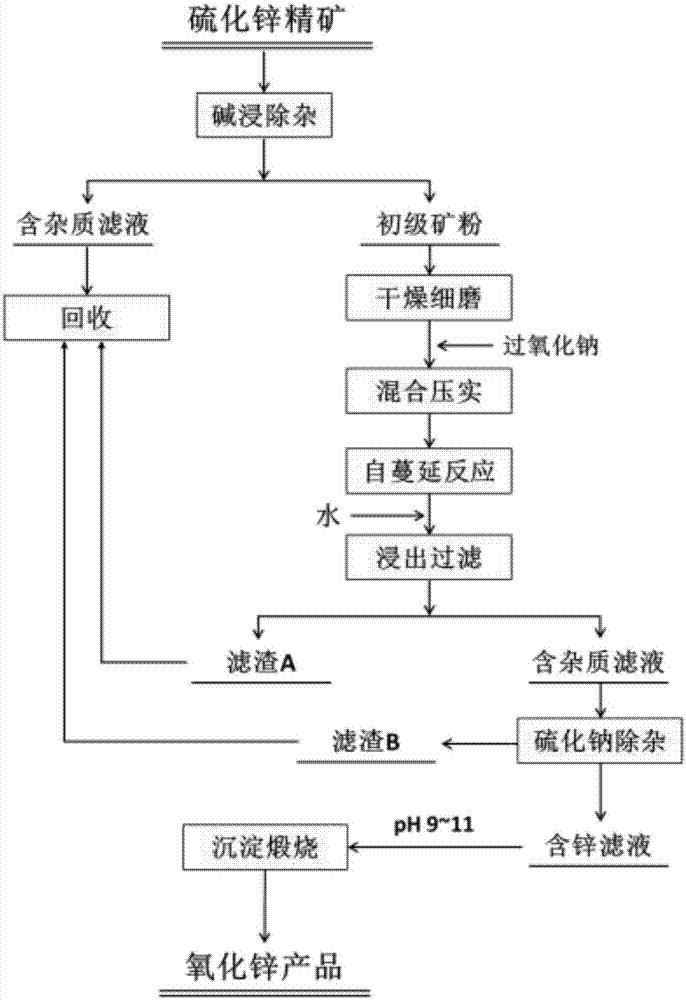

Image

Examples

Embodiment 1

[0034] Soak the separated zinc sulfide concentrate powder in an alkaline solution of sodium hydroxide with a pH of 13 to remove impurities, with a solid-to-liquid ratio of 1:100 (g / mL), a reaction temperature of 30°C, and a reaction time of 4h. Remove impurity silicon and aluminum. After the reaction is filtered, the filter residue is washed with alkaline solution, and the filtrate is used to recover silicon, aluminum, etc. After the filter residue is collected, it is fully dried and crushed for fine grinding. The finely ground ore powder and sodium peroxide are fully stirred and mixed uniformly according to a mass ratio of 1:4, compacted, and placed in a high temperature resistant reaction vessel. The self-propagating reaction is initiated by the chemical ignition method of dripping water. After the reaction product is cooled, it is placed in an alkali-resistant reaction vessel, and zinc is leached with 0.5% sodium hydroxide solution as the leaching agent, the solid-to-liquid ...

Embodiment 2

[0036] Soak the separated zinc sulfide concentrate powder in an alkaline solution of sodium hydroxide with a pH of 12.5 to remove impurities, with a solid-to-liquid ratio of 1:90 (g / mL), a reaction temperature of 35°C, and a reaction time of 3.5h. To remove impurities of silicon and aluminum. After the reaction is filtered, the filter residue is washed with alkaline solution, and the filtrate is used to recover silicon, aluminum, etc. After the filter residue is collected, it is fully dried and crushed for fine grinding. The finely ground ore powder and sodium peroxide are fully stirred and mixed uniformly according to a mass ratio of 1:5, compacted, and placed in a high temperature resistant reaction vessel, and a self-propagating reaction is initiated by microwave ignition. After the reaction product is cooled, it is placed in an alkali-resistant reaction vessel, and zinc is leached with 1% sodium hydroxide solution as the leaching agent, the solid-to-liquid ratio is 1:25 (g / ...

Embodiment 3

[0038] Soak the separated zinc sulfide concentrate powder in an alkaline solution of sodium hydroxide with a pH of 11.8 to remove impurities, with a solid-to-liquid ratio of 1:85 (g / mL), a reaction temperature of 40°C, and a reaction time of 3h. Remove impurity silicon and aluminum. After the reaction is filtered, the filter residue is washed with alkaline solution, and the filtrate is used to recover silicon, aluminum, etc. After the filter residue is collected, it is fully dried and crushed for fine grinding. The finely ground ore powder and sodium peroxide are fully stirred and mixed uniformly according to a mass ratio of 1:4.5, compacted, and placed in a high temperature resistant reaction vessel, and heated by an electric heating plate to initiate a self-propagating reaction. After cooling, the reaction product is placed in an alkali-resistant reaction vessel, and zinc is leached with water as the leaching agent, the solid-liquid ratio is 1:30 (g / mL), the leaching temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com