Preparation method of light-cured base for synthetic leather

A light-curing, synthetic leather technology, used in textiles and papermaking, etc., can solve problems such as water pollution of synthetic leather, and achieve the effects of uniform and fine cells, shape retention and excellent peel strength performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

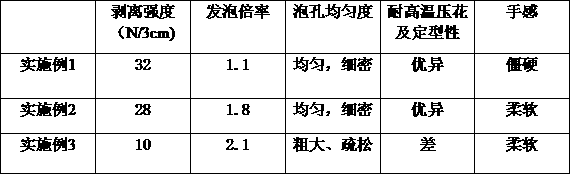

Examples

Embodiment 1

[0020] (1) Preparation of photocurable water-in-oil emulsion

[0021] In the dispersing kettle equipped with high-speed electric shearing machine, constant pressure funnel, ultrasonic vibrating rod, add 100 parts of polyurethane acrylate photocurable resin, 0.5 part of BASF IRGACURE 2959 photoinitiator and 0.5 part of BASF IRGACURE 1173 photoinitiator, non 1 part of ionic emulsifier (Span-80) and 0.5 part of non-ionic emulsifier (Tween-80), at room temperature (25°C), with a shear rate of 1300r / min, ultrasonic rod power of 2000W, through constant pressure 20 parts of saturated sodium chloride aqueous solution were added dropwise to the funnel, and the dropwise addition was complete within 1 hour to form a stable water-in-oil emulsion.

[0022] (2) Coat the water-in-oil emulsion prepared above and the pre-treated non-woven fabric with a coating thickness of 10 microns. At room temperature (25°C), use an ultraviolet light source to cure the water-in-oil emulsion for 20 seconds ...

Embodiment 2

[0024] (1) Preparation of photocurable water-in-oil emulsion

[0025] In the dispersing kettle equipped with high-speed electric shearing machine, constant pressure funnel, ultrasonic vibrating rod, add 100 parts of polyurethane acrylate photocurable resin, 0.5 part of BASF IRGACURE 2959 photoinitiator and 0.5 part of BASF IRGACURE 1173 photoinitiator, non 1 part of ionic emulsifier (Span-80) and 0.5 part of non-ionic emulsifier (Tween-80), at room temperature (25°C), with a shear rate of 1300r / min, ultrasonic rod power of 2000W, through constant pressure 40 parts of saturated aqueous sodium bicarbonate solution was added dropwise to the funnel, and the dropwise addition was completed within 1 hour to form a stable water-in-oil emulsion.

[0026] (2) Coat the water-in-oil emulsion prepared above and the pre-treated non-woven fabric with a coating thickness of 20 microns. At room temperature (25°C), use an ultraviolet light source to cure the water-in-oil emulsion for 30 second...

Embodiment 3

[0028] (1) Preparation of photocurable water-in-oil emulsion

[0029] In the dispersing kettle equipped with high-speed electric shearing machine, constant pressure funnel, ultrasonic vibrating rod, add 100 parts of polyurethane acrylate photocurable resin, 0.5 part of BASF IRGACURE 2959 photoinitiator and 0.5 part of BASF IRGACURE 1173 photoinitiator, non 1 part of ionic emulsifier (Span-80) and 0.5 part of non-ionic emulsifier (Tween-80), at room temperature (25°C), with a shear rate of 1300r / min, ultrasonic rod power of 2000W, through constant pressure The funnel was dripped with 40 parts of saturated aqueous sodium bicarbonate solution, and the addition was complete in 1 hour to form a stable water-in-oil emulsion.

[0030] (2) Coat the water-in-oil emulsion prepared above with a pre-treated non-woven fabric with a coating thickness of 50 microns. At room temperature (25°C), use a UV light source to cure the water-in-oil emulsion for 30 seconds and then dry the cured film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com