Solid electrolyte and capacitor thereof

A solid electrolyte and electrolyte technology, which is applied in the direction of solid electrolytic capacitors, electrolytic capacitor manufacturing, and capacitor parts, etc., can solve the problems of large equivalent series resistance, poor safety, and short life, and achieve the effect of excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

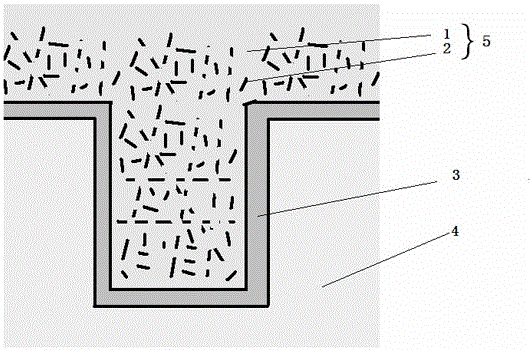

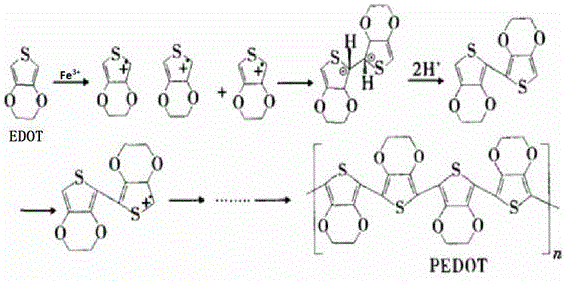

[0030] Dissolve 57 grams of ferric p-toluenesulfonate (DBF) and 9.5 grams of PEG30-b-PSS13 in 300 milliliters of ethanol, heat up to 60°C and stir to dissolve completely, then cool to room temperature; 180 milliliters of 8 grams per liter of graphene The dispersion liquid was gradually added dropwise to the above solution while stirring, and after the dropwise addition was completed, it was ultrasonically treated with a power of 300W for 5 hours to fully disperse;

[0031] After dissolving 71 grams of EDOT in 300 milliliters of ethanol, it was added into the above-mentioned mixed solution, and stirred to form a uniform mixed solution.

[0032] The capacitor core is dipped in the above mixture, heated to 60°C and kept for 4 hours, then heated to 150°C to evaporate the solvent, and then encapsulated and aged.

Embodiment 2

[0034] Dissolve 57 grams of ferric p-toluenesulfonate (DBF) and 9.5 grams of PEG30-b-PSS13 in 300 milliliters of ethanol, raise the temperature to 60°C and stir to dissolve completely, then cool to room temperature; The dispersion liquid was gradually added dropwise to the above solution while stirring, and after the dropwise addition was completed, it was ultrasonically treated with a power of 300W for 5 hours to fully disperse;

[0035] After dissolving 71 grams of EDOT in 300 milliliters of ethanol, it was added into the above-mentioned mixed solution, and stirred to form a uniform mixed solution.

[0036] The capacitor core is dipped in the above mixture, heated to 60°C and kept for 4 hours, then heated to 150°C to evaporate the solvent, and then encapsulated and aged.

Embodiment 3

[0038] 1) Dissolve EDOT in n-butanol to obtain solution 1;

[0039] 2) Add ferric p-toluene sulfonate and block copolymer polyethylene glycol-polystyrene sulfonate into butanol, heat to 70°C and stir to fully dissolve, then cool to room temperature to obtain solution 2, in which The ratio of the sulfonic acid functional group in iron p-toluenesulfonate and block copolymer polyethylene glycol-polystyrene sodium sulfonate is 2:1;

[0040] 3) Slowly add the graphene dispersion into Solution 2 dropwise, while stirring. After the dropwise addition is completed, ultrasonically treat with 250W power to fully disperse to obtain Solution 3. The amount of graphene is 25g / mole iron p-toluenesulfonate;

[0041] 4) Add solution 1 into solution 3, stir to mix evenly to form solution 4, wherein the ratio of 3,4-ethylenedioxythiophene to iron p-toluenesulfonate is 3:2;

[0042] 5) Heat the solution 4 to 100°C and keep it for 150 minutes to allow the polymerization reaction to occur, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com