Plant fiber vegetation blanket and method for manufacturing same

A plant fiber and plant growing blanket technology, which is applied in the direction of seed treatment, chemical instruments and methods, wood layered products, etc., can solve the problems of not being able to see the greening effect immediately, it takes time to grow into a leaf, and the weight of the soil is increased. , to achieve the effect of protecting water and soil erosion, simple structure, and less time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

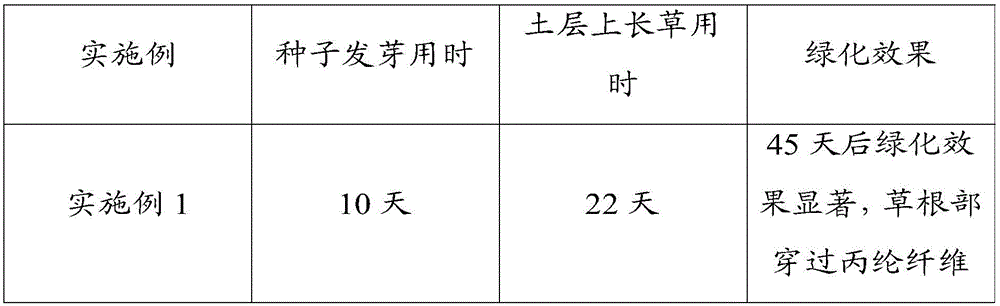

Embodiment 1

[0075] A preparation method of plant fiber planting blanket, comprising the steps of:

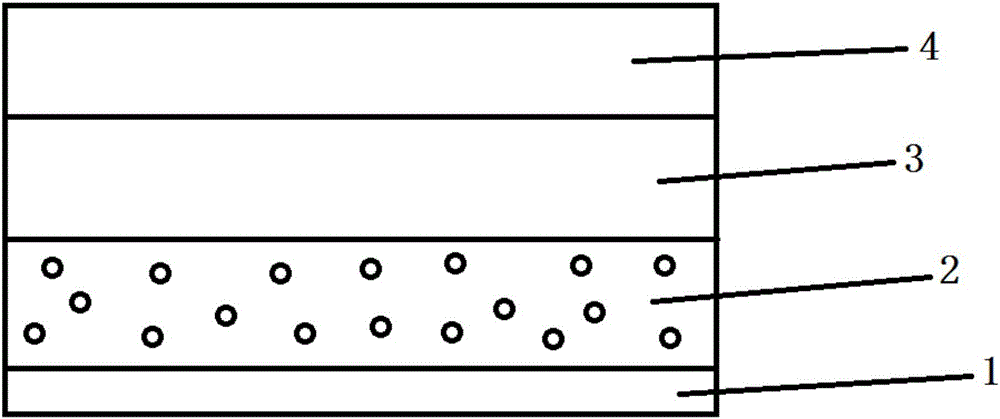

[0076] (1) Lay the polypropylene fiber layer 1 through an opening machine, a carding machine, and a web-laying machine successively by using polypropylene fiber, and prepare a non-woven fabric by using a needle punching machine;

[0077] (2) on the polypropylene fiber layer 1 gained in step (1), sow grass seeds through a planter, and complete the laying of the plant seed layer 2;

[0078] (3) Laying 1 layer of wood pulp paper on the plant seed layer 2 gained in step (2) to obtain a water-retaining layer 3;

[0079] (4) adopt mountain palm fiber, on step (3) gained water-retaining layer 3, lay plant fiber water-locking layer 4 through opening machine, carding machine, netting machine successively;

[0080] (5) The structure obtained in the above steps is interspersed and fixed by a needling machine to obtain a plant fiber planting blanket.

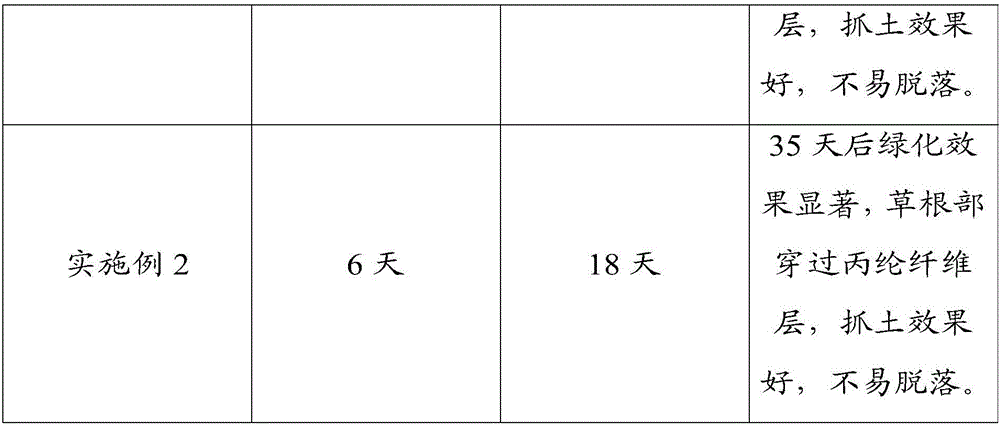

Embodiment 2

[0082] A preparation method of plant fiber planting blanket, comprising the steps of:

[0083] (1) Adopt polypropylene fiber to lay polypropylene fiber layer 1 sequentially through opening machine, carding machine and net-laying machine;

[0084] (2) On the polypropylene fiber layer 1 obtained in step (1), adopt a low-melting point sheath-core composite fiber to lay a low-melting point sheath-core composite fiber layer sequentially through an opener, a carding machine, and a web-laying machine;

[0085] (3) The polypropylene fiber layer 1 obtained in step (2) and the low-melting point sheath-core composite fiber layer are interspersed by a needling machine, and fixed by hot pressing in a hot pressing roller;

[0086] (4) spraying a water-soluble adhesive on the low melting point sheath-core composite fiber layer obtained in step (3);

[0087] (5) Sowing plant seeds and fertilizer on the water-soluble adhesive with a planter to obtain plant seed layer 2;

[0088] (6) Lay 3 la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com