Ssustainable microbial attachment pile for coal chemical wastewater treatment pond

A technology for coal chemical wastewater and microorganisms, which is applied in the methods of supporting/immobilizing microorganisms, bioreactors/fermenters for specific purposes, natural water treatment, etc. effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

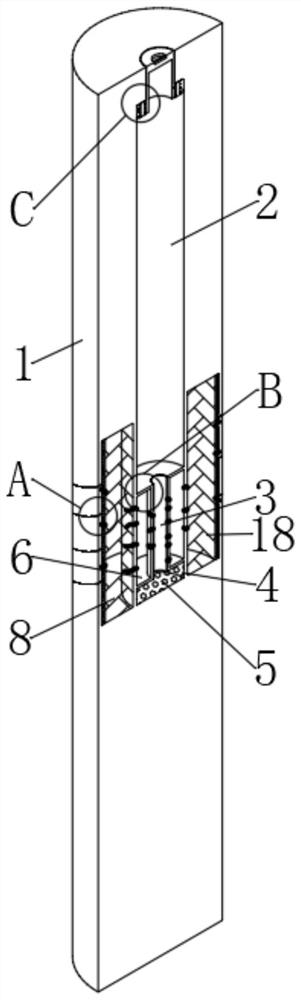

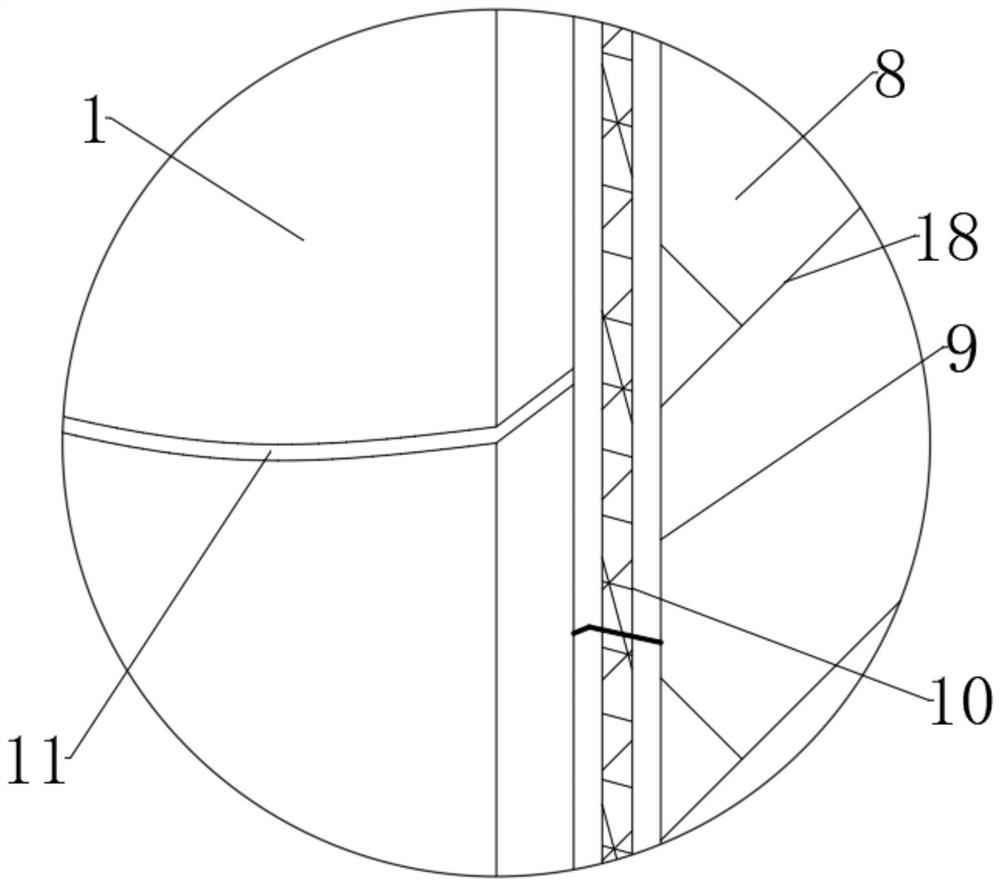

[0037] see Figure 1-6 A sustainable use of microbial attachment piles for coal chemical wastewater treatment pools, comprising a microbial attachment pile main body 1, a filling cavity is excavated in the microbial attachment pile main body 1, and a partition ring is fixedly connected to the inner wall of the filling cavity to fill the space in the cavity With the partition ring as the boundary, it is divided into three parts: supplementary cavity 2, exchange channel 3, waste material area 4 and fixed cavity 6. The supplementary cavity 2 and waste material area 4 are respectively located on the upper and lower sides of the exchange channel 3 and the floating ball 5. The exchange channel 3 communicates with the supplementary chamber 2 and the waste area 4, the fixed chamber 6 is located outside the floating ball 5, and the separated ring is fixedly connected with an exchange semi-permeable membrane 7 matching itself, and the exchange semi-permeable membrane 7 is located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com