Membrane clarification and filtration method for soy sauce

A filtration method and soy sauce technology, applied in chemical instruments and methods, membranes, ultrafiltration, etc., to achieve the effect of controlling membrane pollution and stabilizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

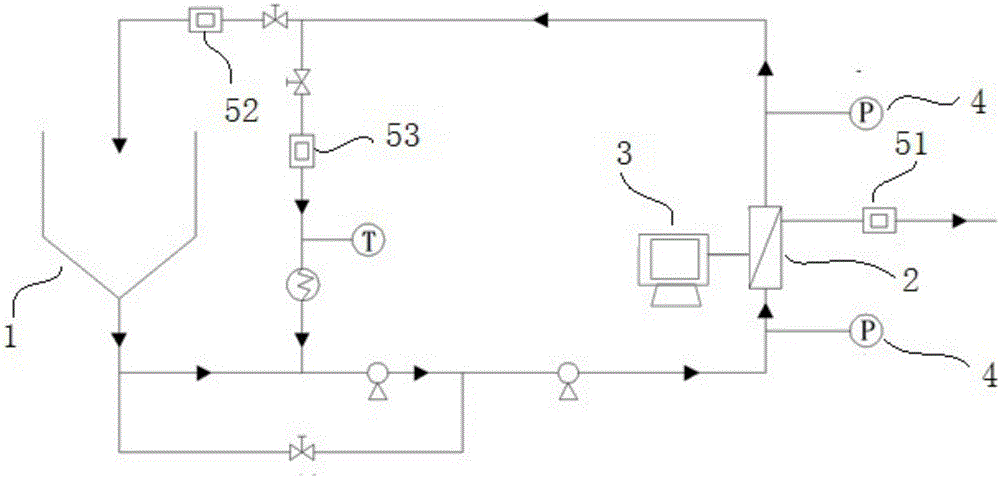

[0039] The soy sauce produced by the high-salt dilute fermentation method is clarified and filtered. In this method, the microfiltration membrane is used to clarify and filter the soy sauce through the coupling and linkage control of the electric field and the flow field. The electric field and the flow field are coupled and controlled by the automatic control system 3. The automatic control system 3 includes a controller and a pressure gauge 4 connected to the controller for detecting the transmembrane pressure difference, a regulating pump for regulating the flow rate of the fluid on the surface of the microfiltration membrane on the raw liquid side, a voltage regulator, a conductivity meter, and a flow meter and sensors such as thermometers, when filtering, such as Figure 1~2 As shown, the feed liquid is filtered from the feed liquid tank 1 through the microfiltration membrane filtration system 2, the pressure gauge 4 is used to feed back the transmembrane pressure differen...

Embodiment 2

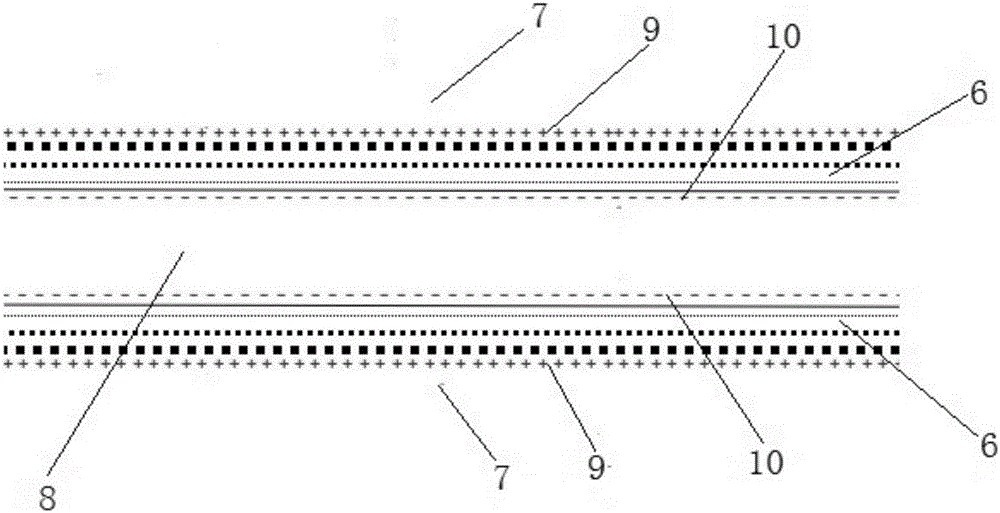

[0042] The soy sauce produced by the high-salt dilute fermentation method is clarified and filtered. The total nitrogen content of the feed liquid is 2.03g / 100ml, the amino acid nitrogen content is 1.27g / 100ml, the salt content is 15.11g / 100ml, the pH is 5.06, and the reducing sugar content is 3.7g / 100ml, the number of colonies is 140 (CFU / ml). For the membrane filtration process, the PVDF microfiltration membrane material with a membrane pore size of 0.2 μm is selected. The temperature is 60°C and the transmembrane pressure difference is 1 bar. The electrode 10 on the passing liquid side and the electrode 9 on the raw liquid side of the microfiltration membrane are supplied with direct current with a voltage of 110-250V, and the electrodes are frequently exchanged. The permeate is the product, and the retention rate of the effective substance of the product is over 99%. After the concentration factor is 50 times, the average flux is 65L.m -2 .h -1 . At the same time, afte...

Embodiment 3

[0044] The soy sauce produced by the high-salt dilute fermentation method is clarified and filtered. The total nitrogen content of the feed liquid is 2.03g / 100ml, the amino acid nitrogen content is 1.27g / 100ml, the salt content is 15.11g / 100ml, the pH is 5.06, and the reducing sugar content is 3.7 g / 100ml, the number of colonies is 140 (CFU / ml). Membrane filtration process chooses 0.1μm microfiltration membrane, material PVDF, temperature 60°C, transmembrane pressure difference 1.5bar, control and adjust the frequency of the frequency converter of the pump from 0 to 50Hz, and the flow rate of the membrane surface fluid on the raw liquid side of the microfiltration membrane is 4~ 10m / s pulse flow, microfiltration membrane permeate side electrode 10 and microfiltration membrane stock solution side electrode 9 are supplied with direct current, the voltage is 110-250V, and the two electrodes are frequently switched. The permeate is the product, the retention rate of the effective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com