Beta-type-hydroxyl-ferric-oxide-loaded natural-cellulose-modified functional material and preparing method and application thereof

A natural cellulose and iron oxyhydroxide technology, applied in chemical instruments and methods, oxidized water/sewage treatment, and other chemical processes, can solve problems such as high cost, failure to meet discharge standards, and high salinity, and achieve strong adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

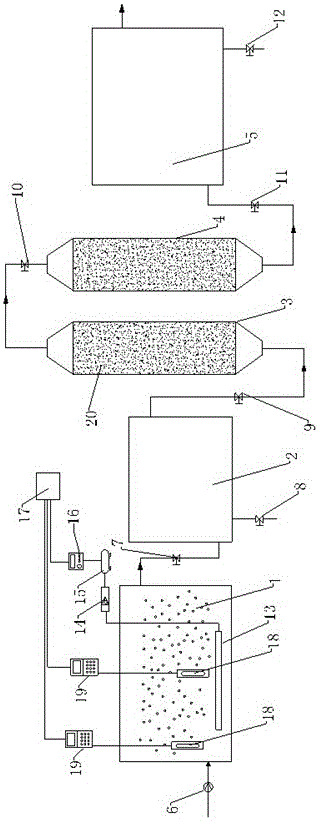

Method used

Image

Examples

Embodiment 1

[0057] A method for preparing a modified natural cellulose functional material loaded with β-type iron oxyhydroxide, comprising the steps of:

[0058] Step (1), preparation of natural cellulose:

[0059] a. Add bagasse to the mixed solvent of ethanol and toluene, stir the reaction at room temperature for 5.5h, filter, wash the filter residue with deionized water to remove the solvent; the solid-liquid ratio of bagasse to ethanol is 1:10; bagasse The solid-to-liquid ratio with toluene is 1:4;

[0060] b. Add the filter residue after washing in step a to the NaClO acidified by acetic acid 2 In the solution, react at 74°C for 1.5h to remove lignin, filter, wash the filter residue with deionized water until neutral, and set aside; bagasse and NaClO acidified with acetic acid 2 The solid-to-liquid ratio of the solution is 1:5.5; the NaClO acidified with acetic acid 2 The solution was prepared by dissolving NaClO 2 Add it to deionized water whose mass is 24 times its mass, and t...

Embodiment 2

[0070] A method for preparing a modified natural cellulose functional material loaded with β-type iron oxyhydroxide, comprising the steps of:

[0071] Step (1), preparation of natural cellulose:

[0072] a. Add bagasse to the mixed solvent of ethanol and toluene, stir and react at room temperature for 5h, filter, wash the filter residue with deionized water to remove solvent; the solid-liquid ratio of bagasse to ethanol is 1:12; bagasse and The solid-to-liquid ratio of toluene is 1:5;

[0073] b. Add the filter residue after washing in step a to the NaClO acidified by acetic acid 2 In the solution, react at 75°C for 1.6h to remove lignin, filter, wash the filter residue with deionized water until neutral, and set aside; bagasse and NaClO acidified with acetic acid 2 The solid-to-liquid ratio of the solution is 1:5.7; the NaClO acidified with acetic acid 2 The solution was prepared by dissolving NaClO 2 Add it to deionized water 25 times its mass, and then adjust the pH to ...

Embodiment 3

[0083] A method for preparing a modified natural cellulose functional material loaded with β-type iron oxyhydroxide, comprising the steps of:

[0084] Step (1), preparation of natural cellulose:

[0085] a. Add bagasse to a mixed solvent of ethanol and toluene, stir and react at room temperature for 6.5 hours, filter, wash the filter residue with deionized water to remove the solvent; the solid-to-liquid ratio of bagasse to ethanol is 1:15; bagasse The solid-to-liquid ratio with toluene is 1:6;

[0086] b. Add the filter residue after washing in step a to the NaClO acidified by acetic acid 2 In the solution, react at 76°C for 2 hours to remove lignin, filter, wash the filter residue with deionized water until neutral, and set aside; bagasse and NaClO acidified with acetic acid 2 The solid-to-liquid ratio of the solution is 1:6; the acetic acid acidified NaClO 2 The solution was prepared by dissolving NaClO 2 Add it to deionized water whose mass is 26 times its mass, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com