Perovskite type lanthanum-manganese-copper catalyst for CO catalytic oxidization and preparation method thereof

A perovskite-type, catalytic oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor low-temperature catalytic oxidation of CO, etc., Achieve the effect of low cost, excellent medium and low temperature catalytic activity, and less preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 3.16g (0.01mol) lanthanum acetate, 2.45g (0.01mol) manganese acetate, and 1.80g (0.02mol) oxalic acid in a mortar and grind for 45 minutes to obtain a lanthanum-manganese composite oxalate precursor; Dry for 1h, then calcinate at 700℃ for 4h, take it out and grind for 15min to obtain catalyst LaMnO 3+δ .

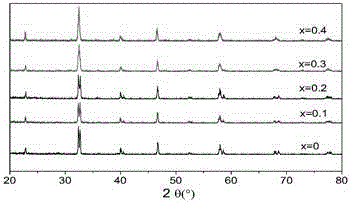

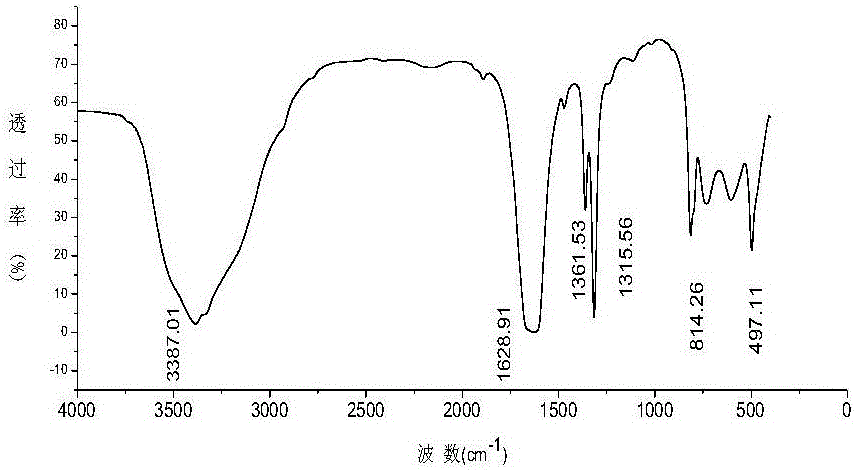

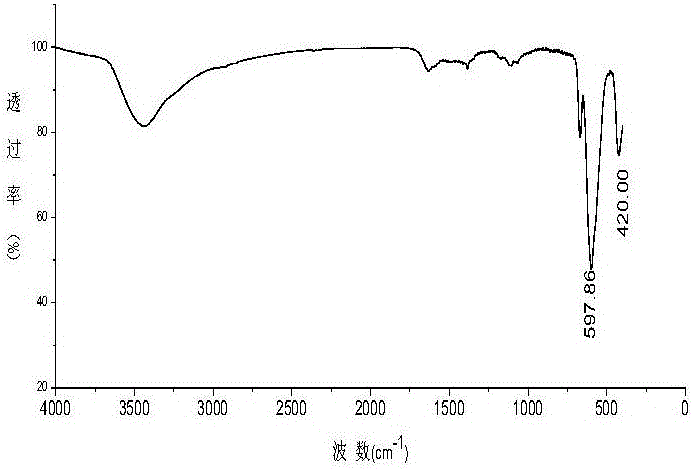

[0034] figure 1 It is the infrared spectrum curve of the precursor of lanthanum manganese composite oxalate; figure 2 LaMnO 3+δ Infrared spectrum curve; image 3 LaMn 1-x Cu x O 3+δ (x=0, 0.1, 0.2, 0.3, 0.4) XRD pattern.

[0035] A fixed-bed reactor evaluation device was used to test the catalytic oxidation performance of the catalyst for CO. For each oxidation performance test, 500 mg of 40-60 mesh catalyst is used. The gas volume fraction for catalyst activity test: 5% CO, 5% O 2 , N 2 Equilibrate, the test temperature is 100~450℃. The performance test results show that the temperature at which the CO catalytic oxidation rate on the prepared catalyst reaches 95%...

Embodiment 2

[0037] Weigh 3.16g (0.01mol) lanthanum acetate, 2.21g (0.009mol) manganese acetate, 0.20g (0.001mol) copper acetate, and 2.70g (0.03mol) oxalic acid in a mortar and grind for 45 minutes to obtain a lanthanum manganese copper composite The oxalate precursor was dried at 80°C for 1 hour, then calcined at 800°C for 5 hours, taken out and ground for 25 minutes to obtain the catalyst LaMn 0.9 Cu 0.1 O 3+δ . The catalyst performance evaluation is the same as in Example 1. The performance test results show that the temperature at which the CO catalytic oxidation rate reaches 95% on the prepared catalyst is 184°C. Figure 5 LaMn 0.9 Cu 0.1 O 3+δ The CO-TPD map.

Embodiment 3

[0039] Weigh 1.63g (0.005mol) lanthanum oxide, 1.96g (0.008mol) manganese acetate, 0.40g (0.002mol) copper acetate, and 3.60g (0.004mol) oxalic acid in a mortar and grind for 45 minutes to obtain a lanthanum manganese copper composite The oxalate precursor was dried at 80°C for 1 hour, then calcined at 850°C for 3 hours, taken out and ground for 20 minutes to obtain the catalyst LaMn 0.8 Cu 0.2 O 3+δ . The catalyst performance evaluation is the same as in Example 1. The performance test results show that the temperature at which the catalytic oxidation rate of CO on the prepared catalyst reaches 95% is 158°C. Image 6 LaMn 0.8 Cu 0.2 O 3+δ The CO-TPD map.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com