Solid Fenton catalyst and preparation method and application thereof

A catalyst and solid technology, applied in the field of solid Fenton catalyst and its preparation, can solve the problems of harsh reaction conditions, low utilization rate of hydrogen peroxide, poor catalytic activity, etc., and achieves low cost, easy recovery and recycling, and high utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

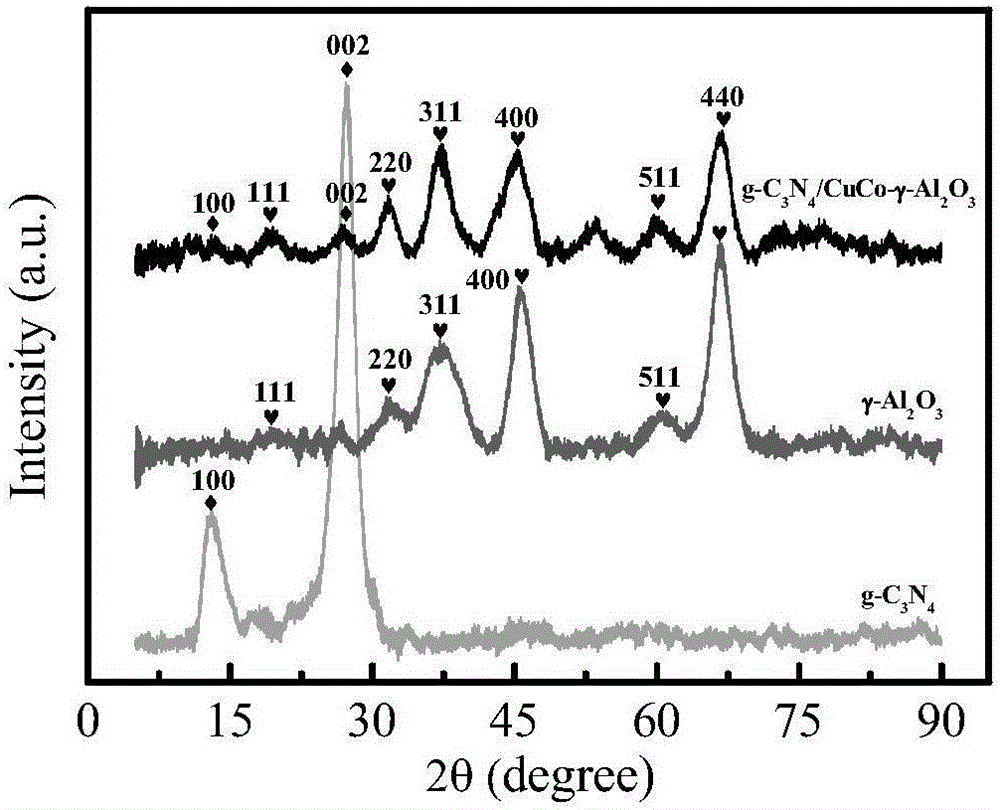

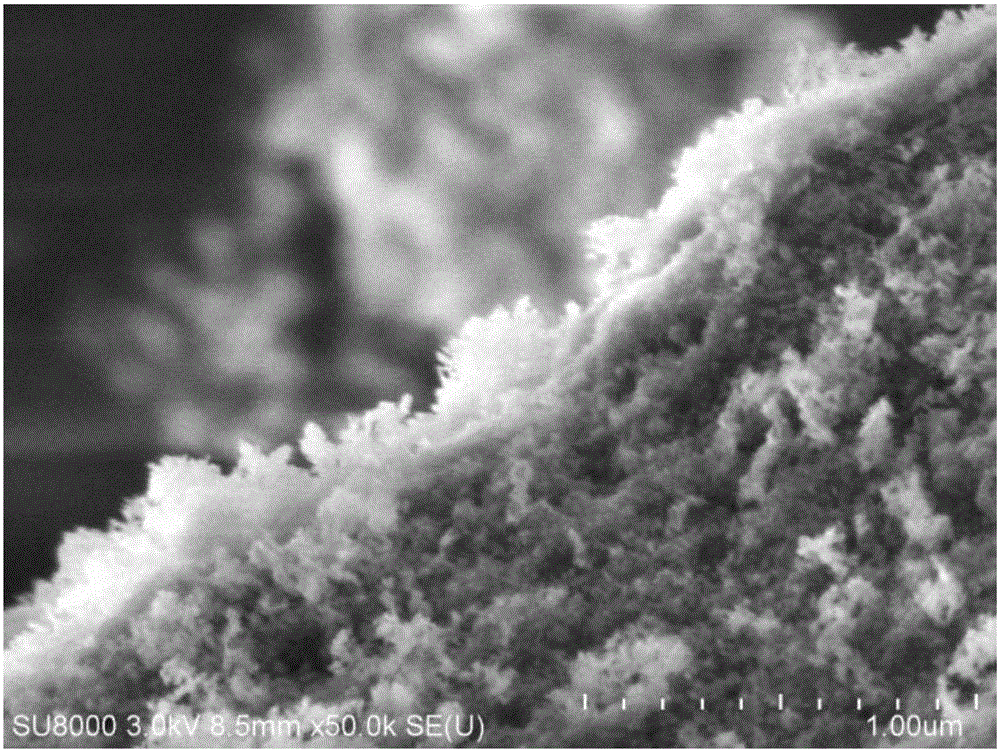

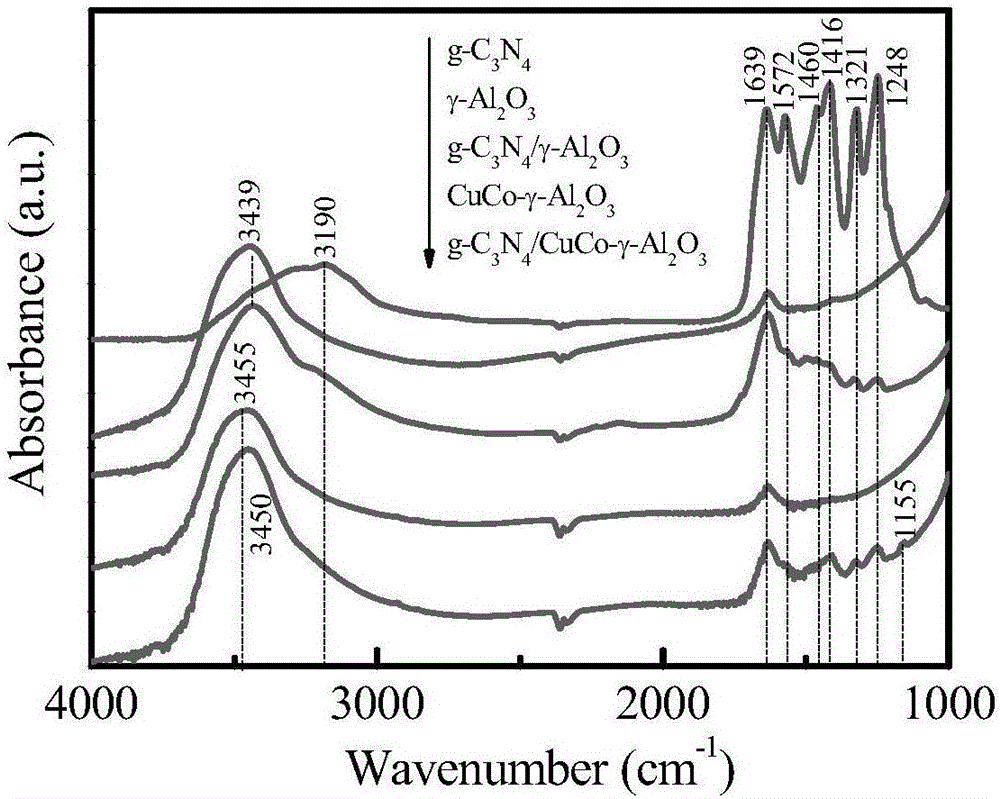

[0040] Embodiment 1, preparation and application experiment of solid Fenton catalyst

[0041] 1. Preparation

[0042] The copper-cobalt co-doped mesoporous alumina solid Fenton catalyst (g-C 3 N 4 / CuCo-γ-Al 2 o 3 ):

[0043] (1) Dissolve 7.2g of glucose into 100mL of deionized water, then add 8.4g of powdered aluminum isopropoxide, and mix and stir for 2 hours (rotating at 450 rpm) to form solution A;

[0044] (2) 0.5g copper chloride dihydrate (CuCl 2 2H 2 O) and 0.3g cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) Dissolve in 10mL deionized water, and add the solution dropwise to solution A, fully stir (stirring time is 30 minutes, rotating speed is 450 rpm), to form solution B;

[0045] (3) The pH of solution B is gradually adjusted to 5 with aqueous hydrochloric acid (the mass percentage of hydrochloric acid is 1%), and the resulting solution is stirred in a water bath at 50° C. for 5 hours (rotating speed is 450 to 700 rpm) , to form solution C; solution C was lef...

Embodiment 2

[0075] Embodiment 2, prepare different g-C 3 N 4 σ-surface copper-graphitized nitrogen carbide complex-modified copper-cobalt co-doped mesoporous alumina solid Fenton catalysts.

[0076] Follow the steps below to prepare different g-C 3 N 4 g-C 3 N 4 / CuCo-γ-Al 2 o 3 :

[0077] (1) Dissolve 7.2g of glucose into 100mL of deionized water, then add 8.4g of powdered aluminum isopropoxide, and mix and stir for 2 hours (rotating at 450 rpm) to form solution A;

[0078] (2) 0.5g copper chloride dihydrate (CuCl 2 2H 2 O) and 0.3g cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) Dissolve in 10mL deionized water, and add the solution dropwise to solution A, fully stir (stirring time is 30 minutes, rotating speed is 450 rpm), to form solution B;

[0079] (3) The pH of solution B is gradually adjusted to 5 with aqueous hydrochloric acid (the mass percentage of hydrochloric acid is 1%), and the resulting solution is stirred in a water bath at 50°C for 5 hours, and after standing at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com