Casting high-chromium alloy modeling method based on molecular dynamics

A molecular dynamics and high-chromium alloy technology, which is applied in the modeling field of high-chromium alloy based on molecular dynamics method, can solve the problems such as the vacancy of the theoretical model of new high-chromium alloy performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] The specific implementation of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

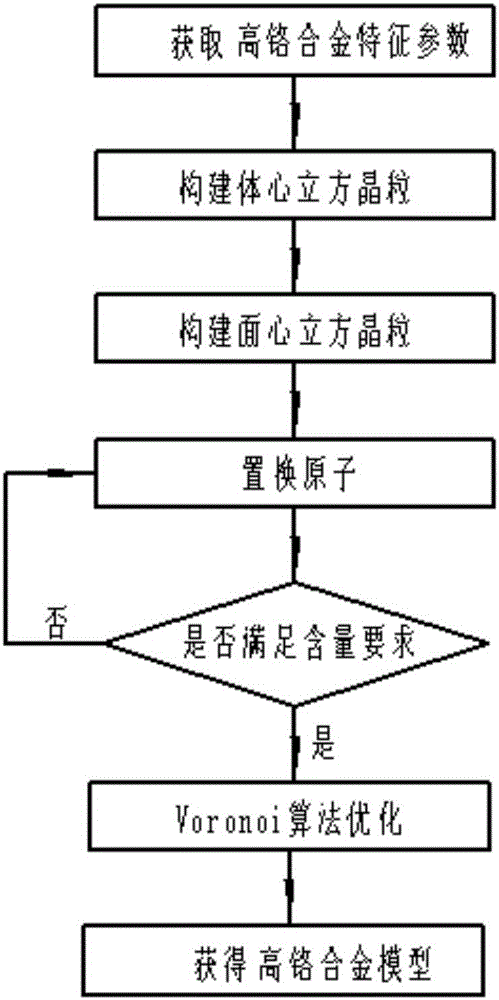

[0019] figure 1 It is a flow chart of the method for establishing a cast high-chromium alloy model in the present invention. First, obtain the characteristic parameters of the cast high-chromium alloy model: the type of element, the volume fraction of various elements, the mass fraction, the solidification temperature of each element, and the distance between particles and grains. size and grain distribution. Wherein, the element types include molybdenum (Mo), copper (Cu), nickel (Ni), iron (Fe), manganese (Mn), chromium (Cr), vanadium (V), silicon (Si), and sulfur (S). During the molecular dynamics simulation, the workpiece and tool models are arranged according to the rules of atomic composition.

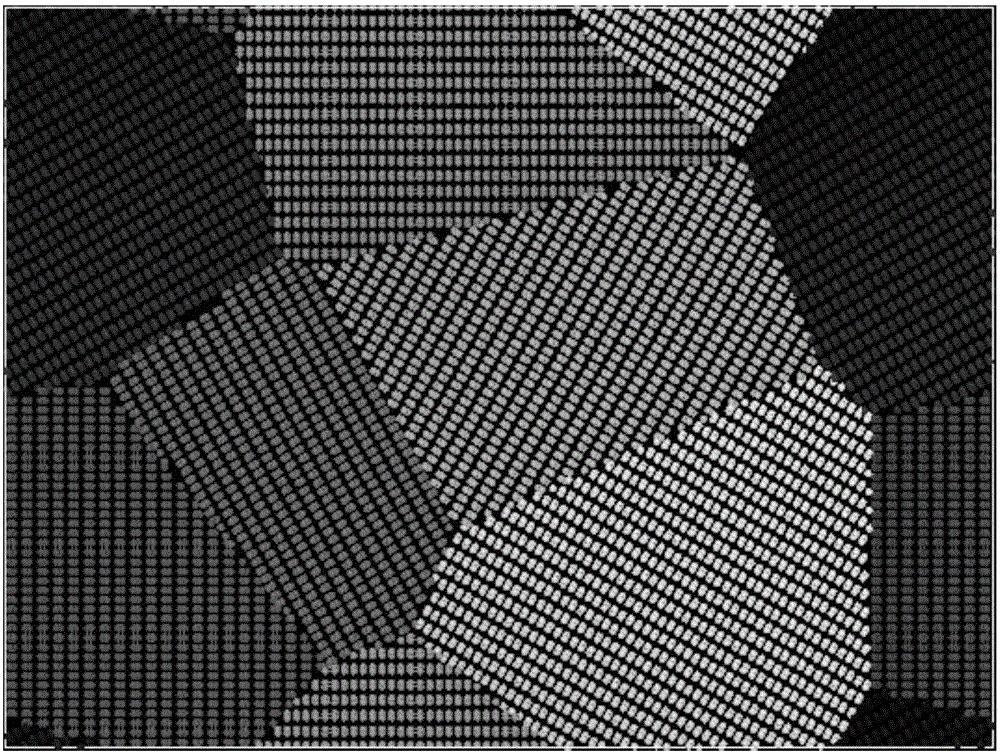

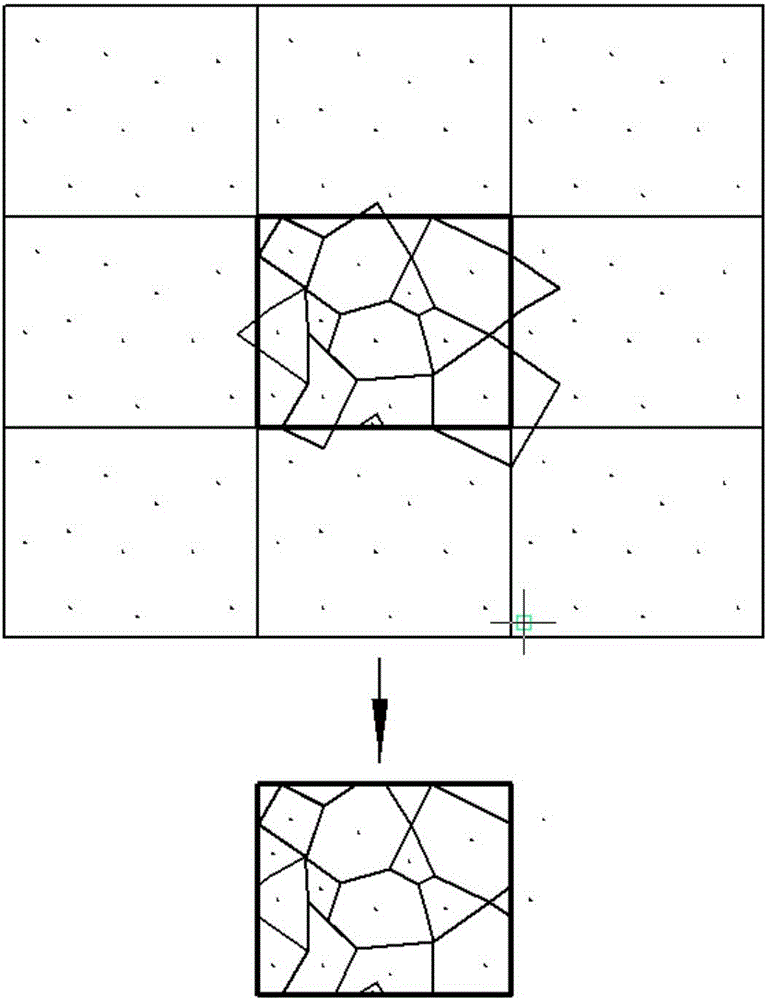

[0020] In step 2 and step 3, since there are different forms of microstructu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com