A kind of preparation method of nano aluminum hydroxide in aluminum rock

A technology of nano-aluminum hydroxide and aluminum rock, applied in chemical instruments and methods, nanotechnology, aluminum compounds, etc., can solve the problems of low purity of nano-alumina hydroxide, expensive equipment purchase cost, and easy introduction of new impurities. Achieve the effects of shortening the preparation time, accelerating the ion migration speed, and fast chemical reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

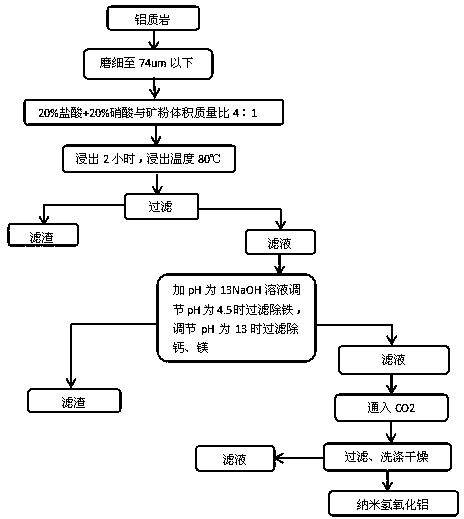

[0033] Embodiment 1: a kind of preparation method of nanometer aluminum hydroxide in aluminum rock, this method comprises the following steps:

[0034] (1) Using alumina rock as raw material, Al 2 o 3 The content is 30%. After crushing it with a jaw crusher, use a ball mill to grind the crushed ore to a particle size below 74um. After the aluminum rock is finely ground, the specific surface area is increased to make the reaction fully and completely, and the reaction is faster. Higher efficiency, and beneficial to the Al 2 o 3 more thorough leaching;

[0035] (2) After drying the mineral powder sample ground in step (1), put the mixed solution of hydrochloric acid and nitric acid and the dried mineral powder in a water bath in proportion to stir, and the mixed solution used is 20% concentrated by volume fraction Hydrochloric acid and 20% concentrated nitric acid, the liquid-solid ratio, that is, the mass ratio of the mixed acid volume to the mineral powder, is 4:1, the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com