A method for CO2 reduction by metal oxide modified electrode biofilm

An oxide and biofilm technology, applied in chemical instruments and methods, electrochemical biocombination treatment, separation methods, etc., to achieve the effects of low price, improved ability to obtain electrons, and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

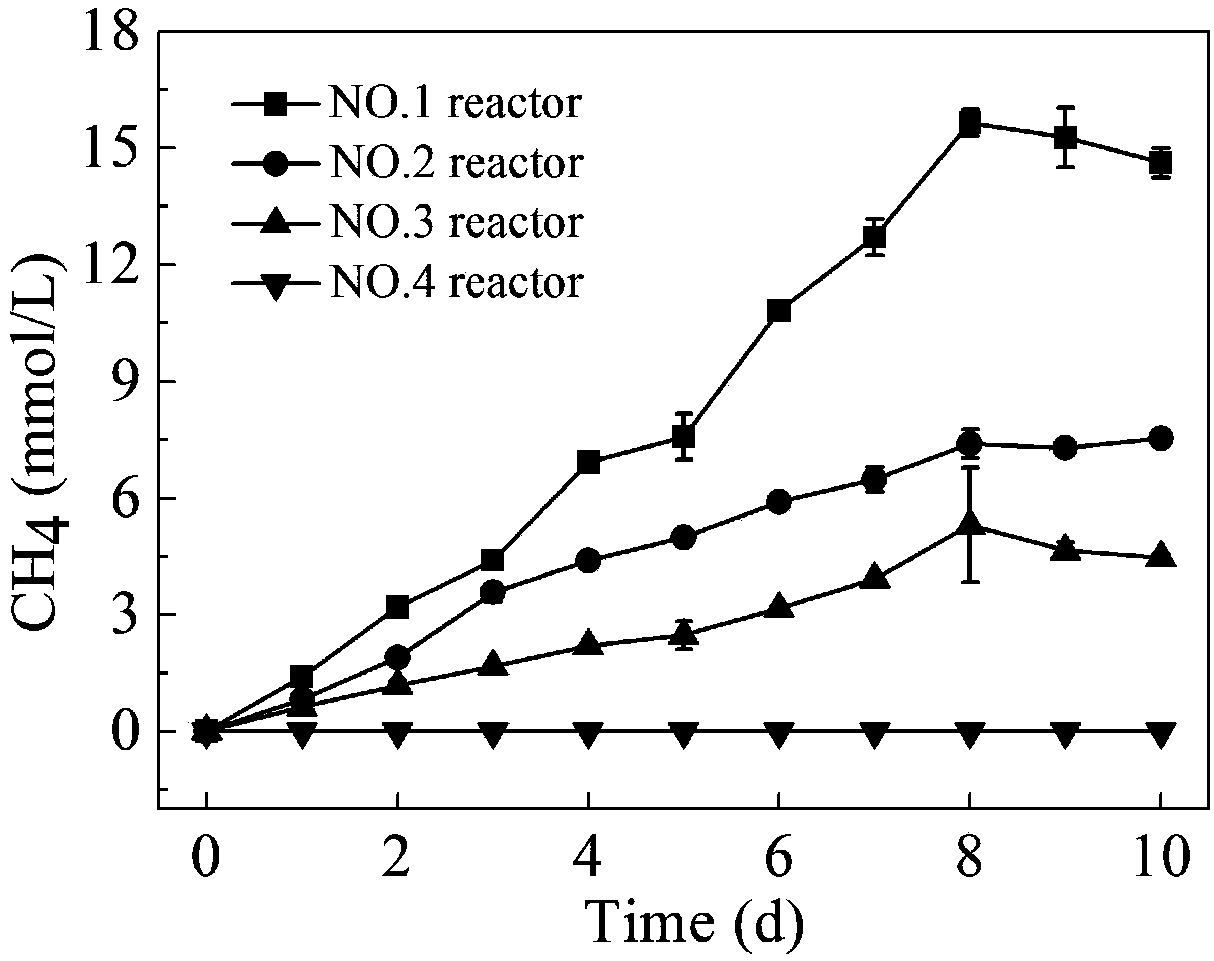

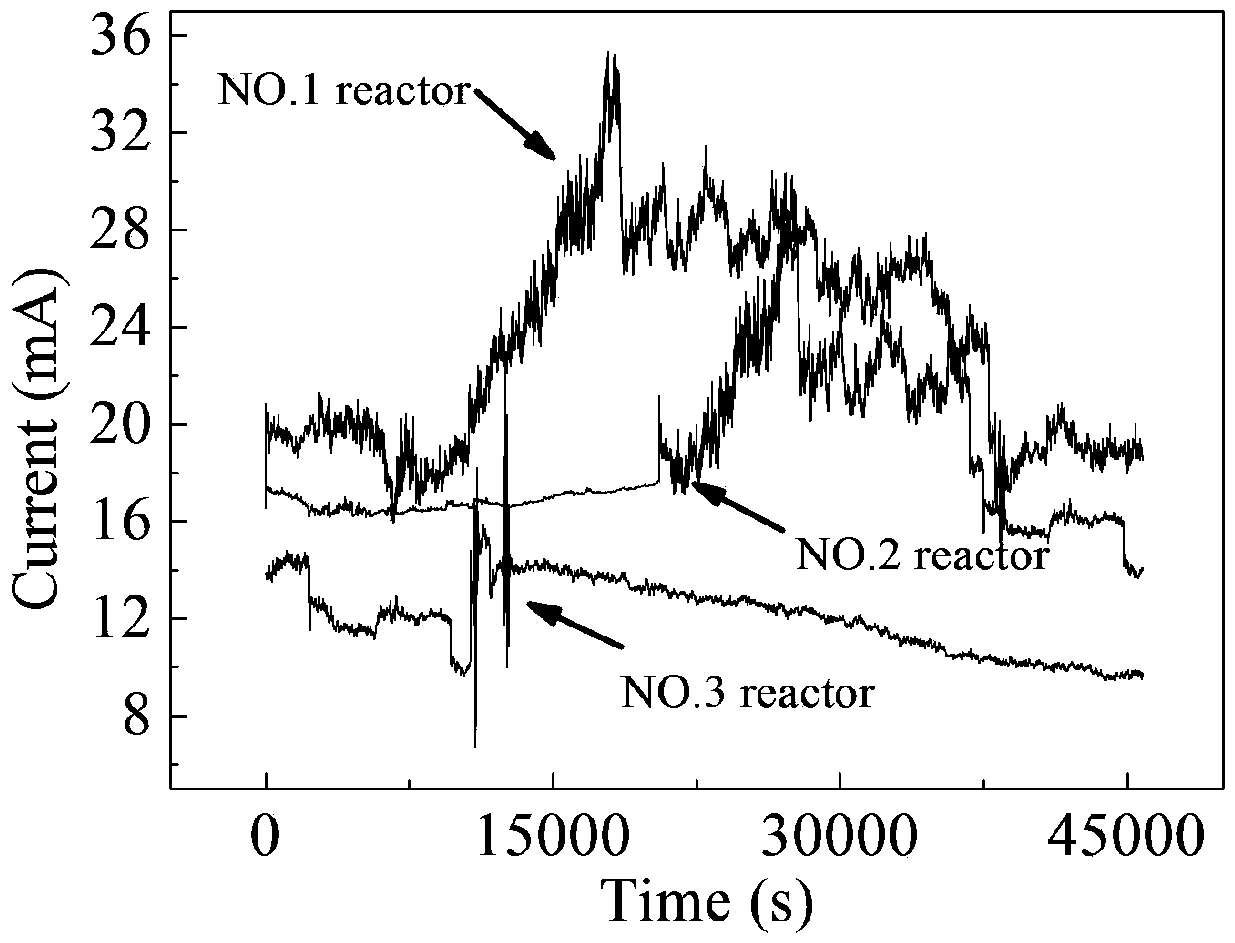

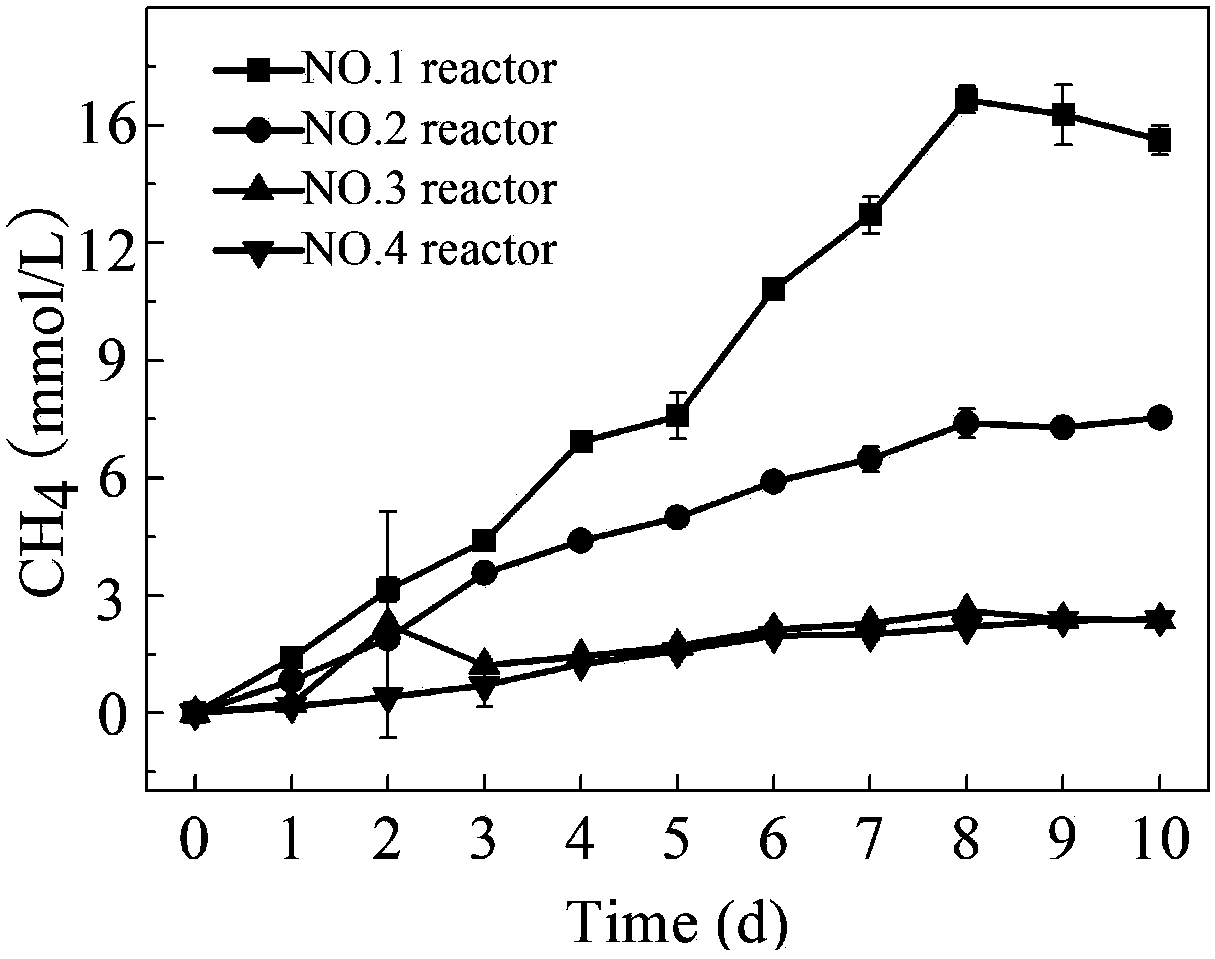

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Step (1): Using a three-electrode system for CV scanning to prepare iron oxide modified conductive carbon cloth:

[0065] In a three-electrode system, Fe 2+ The precursor solution is used as the electrolyte, the conductive substrate is used as the working electrode, the titanium electrode is used as the counter electrode, and the Ag / AgCl electrode is used as the reference electrode; the specific steps are as follows:

[0066] Step (1-1): Take 200mL acetate buffer solution (the concentration of sodium acetate is 0.2mol / L) and configure 10mmol / L FeSO 4 solution, and adjust the pH of the solution to 7.0 with acetic acid to obtain Fe 2+ The precursor solution;

[0067] Step (1-2): the configured Fe 2+ The precursor solution was transferred to the beaker, the above-mentioned three-electrode system was installed, and connected to the electrochemical workstation.

[0068] Step (1-3): Set the CV scanning range of the workstation to 0.1-1.6V, the scanning speed to 50mV / s, an...

Embodiment 2

[0076] The difference from Example 1 is that in step (1), Cu 2+ The precursor solution was used to modify the conductive carbon cloth.

[0077] Cu 2+ The precursor solution is Cu(CH with a concentration of 10mmol / L 3 COO) 2 An acetate-buffered saline solution with a pH of 5.5.

[0078] The CV scanning range of the workstation is -1.0-0.4V, the scanning speed is 50mV / s, and the number of scanning circles is 50 circles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com