Method for extracting hypericin from Hypericum perforatum

A technology of Hypericum perforatum and hypericin, applied in organic chemistry, quinone separation/purification, etc., can solve the problem of low extraction rate, achieve the effect of increasing extraction rate, shortening solvent extraction time, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

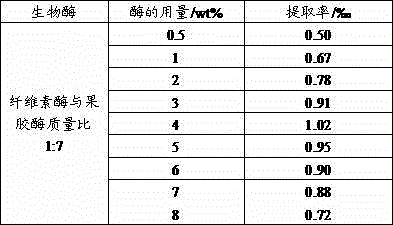

[0045] Embodiment 1: the kind of biological enzyme and dosage screening

[0046] Step (1): Processing raw materials

[0047] After washing the flowers and leaves of Hypericum perforatum, put them in a blast drying oven, dry them at a temperature of 35°C until the water content is less than 10%, then crush them with high speed shearing, sieve, and collect the parts with a particle size of 100-200 mesh , to obtain Hypericum perforatum powder.

[0048] Step (2): Enzyme treatment

[0049] Under an inert gas such as a nitrogen atmosphere, add Hypericum perforatum powder and biological enzymes to water, wherein the Hypericum perforatum powder is 100g, and the mass ratio of Hypericum perforatum powder to water is 1:12. The type and amount of added enzymes are shown in Table 1 and Table 2, so as to prepare the Hypericum perforatum enzyme solution; then adjust the pH of the enzyme solution to 5.0, put it in a constant temperature shaker after the adjustment, the shaker speed is 110r...

Embodiment 2

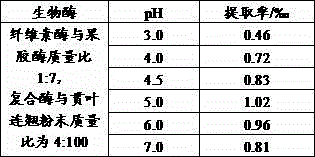

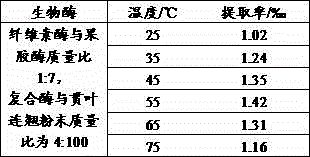

[0057] Embodiment 2: the screening of pH and temperature in enzymolysis process

[0058] Step (1): Processing raw materials

[0059] After washing the flowers and leaves of Hypericum perforatum, put them in a blast drying oven, dry them at a temperature of 35°C until the water content is less than 10%, then crush them with high speed shearing, sieve, and collect the parts with a particle size of 100-200 mesh , to obtain Hypericum perforatum powder.

[0060] Step (2): Enzyme treatment

[0061] Under inert gas such as nitrogen atmosphere, add Hypericum perforatum powder and compound enzyme to water, wherein Hypericum perforatum powder is 100g, the mass ratio of Hypericum perforatum powder and water is 1:12, and described compound enzyme is cellulase and pectinase The mixture, wherein the mass ratio of cellulase and pectinase is 1:7, the mass ratio of the sum of the quality of the compound enzyme and Hypericum perforatum powder is 4:100, thereby preparing Hypericum perforatum...

Embodiment 3

[0069] Embodiment 3: the investigation of the kind of ultrasonic extraction solvent, solid-liquid ratio and alkali consumption

[0070] Step (1): Processing raw materials

[0071] After washing the flowers and leaves of Hypericum perforatum, put them in a blast drying oven, dry them at a temperature of 35°C until the water content is less than 10%, then crush them with high speed shearing, sieve, and collect the parts with a particle size of 100-200 mesh , to obtain Hypericum perforatum powder.

[0072] Step (2): Enzyme treatment

[0073] Under inert gas such as nitrogen atmosphere, add Hypericum perforatum powder and compound enzyme to water, wherein Hypericum perforatum powder is 100g, the mass ratio of Hypericum perforatum powder and water is 1:12, and described compound enzyme is cellulase and pectinase The mixture, wherein the mass ratio of cellulase and pectinase is 1:7, the mass ratio of the sum of the quality of the compound enzyme and Hypericum perforatum powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com