Preparation method of liquid light-cured solder resist ink and photosensitive resin thereof

A technology of solder mask ink and photosensitive resin, which is applied in the direction of ink, optical mechanical equipment, photoplate making process of pattern surface, etc. Good adhesion, good anti-acid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

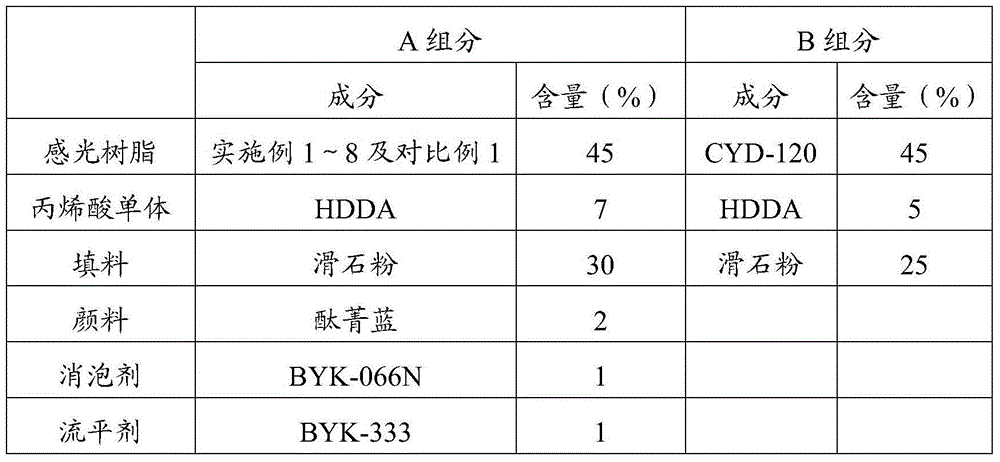

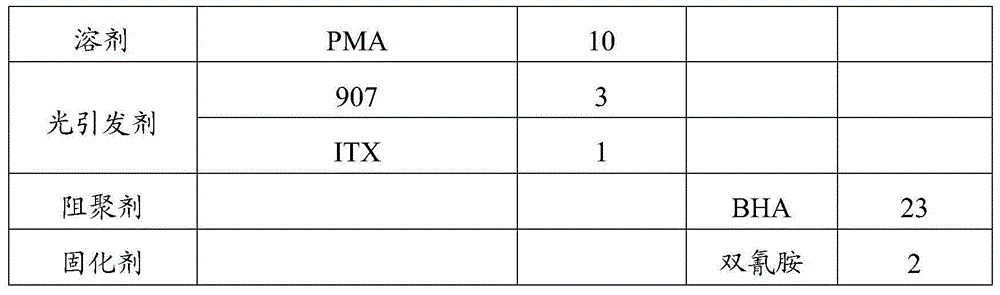

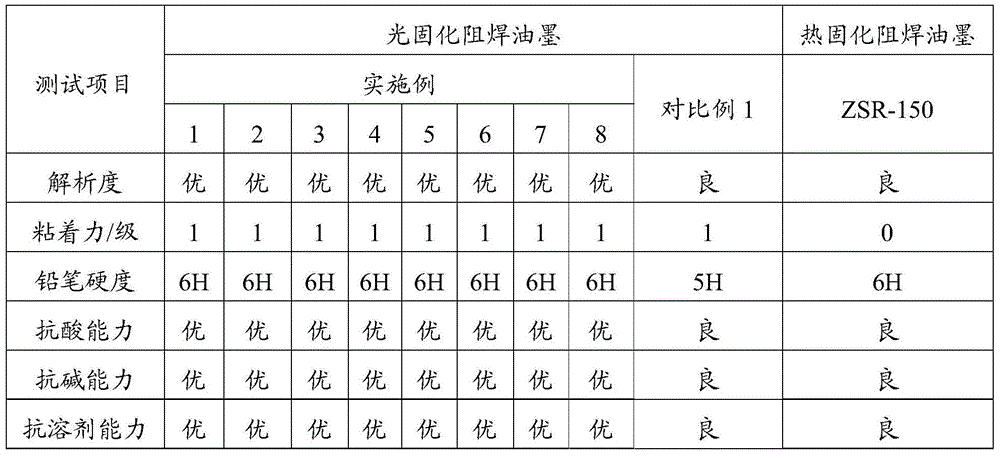

Examples

preparation example Construction

[0066] Since the properties of the photosensitive resin affect the properties of the solder resist ink, the second aspect of the present invention provides a method for preparing the photosensitive resin in the liquid photocurable solder resist ink of the first aspect of the present invention, making acrylic acid, acid anhydride and initial epoxy Resin fully reacts, and described preparation method comprises the following steps:

[0067] Step (1), at 75 ℃~85 ℃, epoxy resin is dissolved in the solvent, then add acrylic acid, catalyst and polymerization inhibitor, the mol ratio of the epoxy group of described acrylic acid and epoxy resin is (0.80~ 1.20): (0.80~1.20), heat up to 95°C~115°C for reaction until the acid value is lower than 2mgKOH / g, terminate the reaction to obtain an intermediate product of epoxy acrylate; The resin is selected from at least one of E12, E12A, E13, E14, ECN268, ECN273, ECN280;

[0068] Step (2), according to the hydroxyl molar ratio of acid anhydri...

Embodiment 1

[0083] Step (1), in a 1000mL four-necked bottle equipped with a stirrer, a condenser, and a thermometer, add 200.00g of CYD-012 epoxy resin and 140.94g of diethylene glycol monoethyl ether acetate at 80°C, and stir until the epoxy resin Add 20.45g of acrylic acid after dissolving completely, account for reaction system (epoxy resin, diethylene glycol monoethyl ether acetate, acrylic acid) mass ratio is 2% catalyst triphenylphosphine and 0.01% polymerization inhibitor 2,6-di tert-butyl-4-methylphenol. Gradually raise the temperature to 95°C to carry out the reaction. Measure the acid value according to the GB2895-82 method, until the acid value drops below 2 mgKOH / g, the reaction is terminated to obtain 368.61 g of epoxy acrylate intermediate product.

[0084] Step (2), under stirring, the epoxy acrylate intermediate product obtained in step (1) is warmed up to 60° C., and then adding the catalyst 4- Dimethylaminopyridine and 0.01% polymerization inhibitor 2,6-di-tert-butyl-4...

Embodiment 2

[0086]Step (1), in a 1000mL four-necked bottle equipped with a stirrer, a condenser, and a thermometer, add 200.00g of CYD-012 epoxy resin and 140.94g of diethylene glycol monoethyl ether acetate at 80°C, and stir until the epoxy resin Add 20.45g of acrylic acid after dissolving completely, account for reaction system (epoxy resin, diethylene glycol monoethyl ether acetate, acrylic acid) mass ratio is 2% catalyst triphenylphosphine and 0.01% polymerization inhibitor 2,6-di tert-butyl-4-methylphenol. Gradually raise the temperature to 95°C to carry out the reaction. Measure the acid value according to the GB2895-82 method, until the acid value drops below 2 mgKOH / g, the reaction is terminated to obtain 368.61 g of epoxy acrylate intermediate product.

[0087] Step (2), under stirring, the epoxy acrylate intermediate product obtained in step (1) is warmed up to 80 ° C, and then adding the catalyst 4- Dimethylaminopyridine and 0.01% polymerization inhibitor 2,6-di-tert-butyl-4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com