Modified polythiophene organic magnetic resistance film material, preparation method therefor and application thereof

A thin-film material, polythiophene technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of poor electrical conductivity, low magnetoresistance response sensitivity, etc. Solve the effect of poor conductivity and enhanced magnetoresistance response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing an organic magnetoresistive thin film material, comprising the following steps:

[0037] 1) After mixing polythiophene compounds and condensed ring aromatic hydrocarbon derivatives in an organic solvent, a mixed solution is obtained;

[0038] 2) After the mixed solution obtained in the above steps is formed into a film, an organic magnetoresistive thin film is obtained.

[0039] In the present invention, the selection and ratio of raw materials in the preparation process of the organic magnetoresistive thin film material are optimized, unless otherwise specified, corresponding to the uniformity of the aforementioned organic magnetoresistive thin film material, and will not be repeated here.

[0040] In the invention, firstly, the polythiophene compound and the polycyclic aromatic hydrocarbon derivative are mixed in an organic solvent to obtain a mixed liquid.

[0041] The present invention is not particularly limited to the...

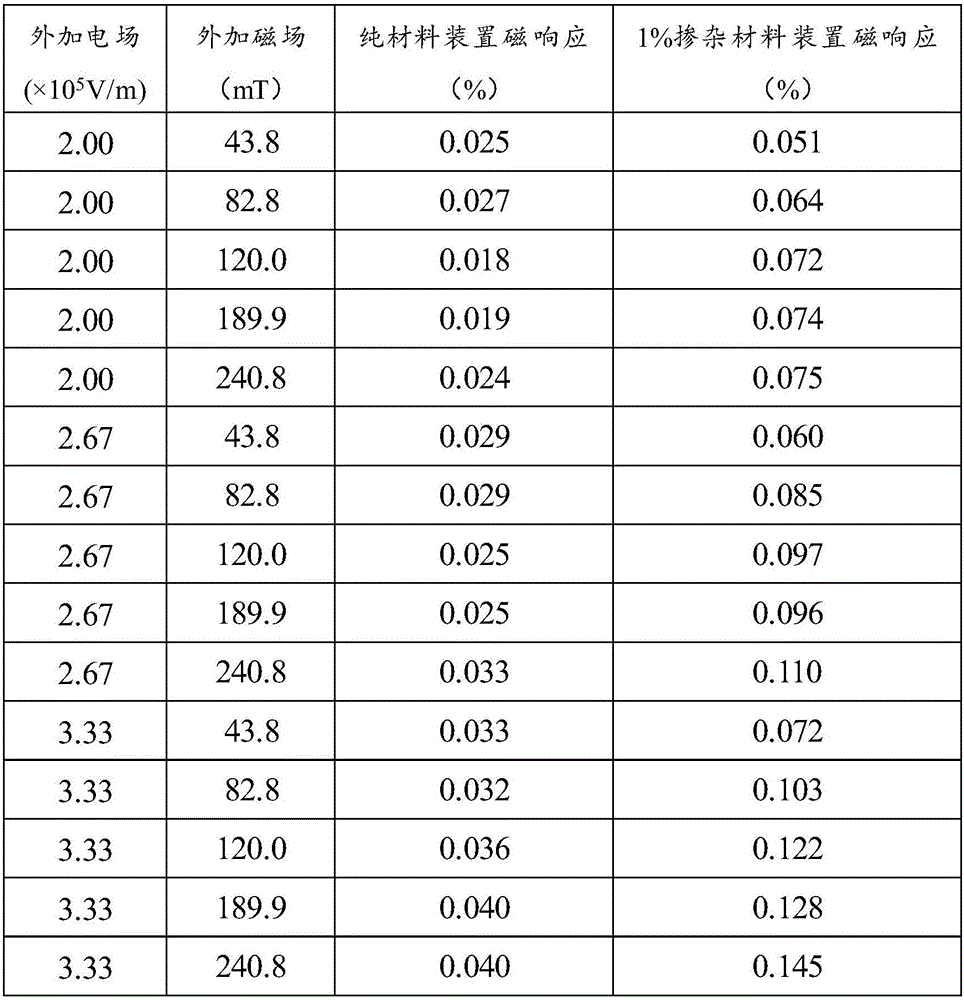

Embodiment 1

[0061] Preparation of Pentacene / 3-Hexyl-substituted Polythiophene Composite Organic Thin Films

[0062] First, set the doping ratio of 1%, and set the concentration of the prepared mixed solution to 30 mg / ml. By calculation, 1 ml of the solution contains 29.7 mg of 3-hexyl-substituted polythiophene and 0.3 mg of pentacene.

[0063] Using an electronic balance with an accuracy of 0.01 mg, weigh 30.0 mg of pentacene and dissolve it in 100.0 ml of o-dichlorobenzene solvent, accelerate the dissolution by heating and magnetic stirring, and prepare a 0.3 mg / ml pentacene solution.

[0064] 29.7 mg of 3-hexyl-substituted polythiophene was obtained by weighing with an electronic balance with an accuracy of 0.01 mg.

[0065]Use a 1.0mL pipette gun to take 1.0ml of the above-prepared pentacene solution, dissolve the above-mentioned weighed 29.7 mg of 3-hexyl-substituted polythiophene in this solution, accelerate the dissolution by heating, magnetic stirring, etc., and prepare 30mg / mL mi...

Embodiment 2

[0080] Preparation of Pentacene / 3-Hexyl-substituted Polythiophene Composite Organic Thin Films

[0081] Solution preparation process is identical with example 1.

[0082] Using a bar coater, spread it evenly on the electrode at a constant spreading speed. After the solvent o-dichlorobenzene volatilizes, a pentacene / 3-hexyl substituted polythiophene composite organic film is formed.

[0083] A pure 3-hexyl substituted polythiophene organic film without doping materials is prepared by using 3-hexyl substituted polythiophene according to the above concentration ratio.

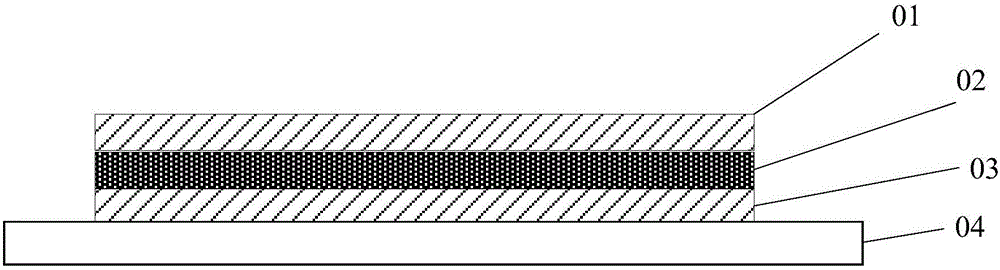

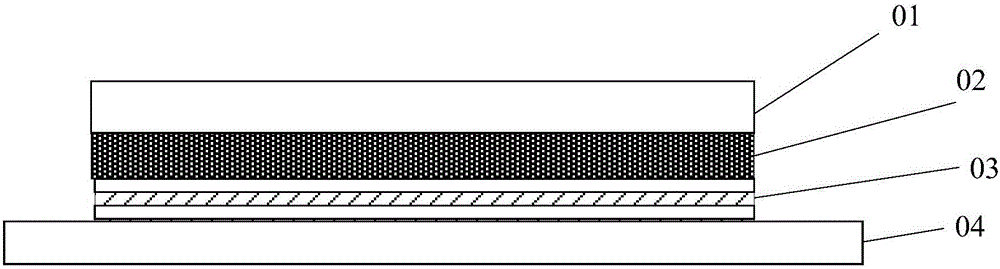

[0084] Fabrication of Organic Magnetoresistive Thin Film Components on Flexible Substrates

[0085] see figure 2 , figure 2 A simplified diagram of the structure of a flexible organic diode electronic accessory with a magnetoresistive effect provided by an embodiment of the present invention.

[0086] figure 2 Polyethylene was selected as the base layer 04, 50 nanometers of indium tin oxide, 50 nanometers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com