Distributed energy resource station applied to LNG (Liquefied Natural Gas) plant

A distributed energy and entry-side technology, applied in the field of distributed energy stations applied to LNG liquefaction plants, can solve the problems of large power consumption, low energy utilization rate, and high operating costs, and achieve the effect of meeting power supply requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

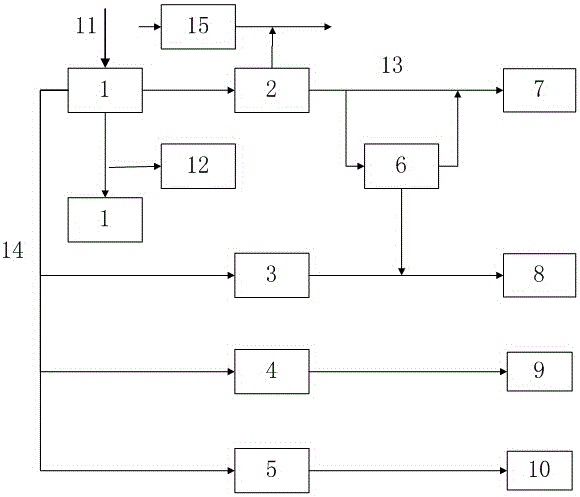

[0017] Such as figure 1 As shown, the distributed energy station applied to the LNG liquefaction plant of the present invention includes a power generation part, a jacket water waste heat utilization part and a flue gas waste heat utilization part. 10.5KV high-voltage power grid 12, cylinder jacket water waste heat utilization part includes domestic hot water heat exchanger 3, heating heat exchanger 4 and low-temperature waste heat ORC screw generator set 5, flue gas waste heat utilization part includes flue gas heat transfer oil furnace 2 and flue gas heat exchanger 6. The inlet end of the gas internal combustion generator set 1 is connected to the natural gas pipeline network 11, and generates electricity through the mixed combustion of natural gas and air. Power transmission, together with the original system to supply power to the factor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com