Artificial feed for bat moth larvae and preparation method thereof

A technology of bat moth larvae and artificial feed, which is applied to the preservation method of animal feed raw materials, animal feed, animal feed and other directions, can solve the problems of difficulty in large-scale breeding, difficulty in mating and reproduction, insufficient nutrition of bat moth larvae, etc., and achieves convenient feeding. Feeding, feeding effect is good, easy to apply and promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method for bat moth larvae artificial feed, specifically comprises the steps:

[0022] (1) After sterilizing wheat bran, fish meal, corn meal, soybean meal, Polygonum barbadensis powder and yeast powder in a high-pressure steam sterilizer at 121 degrees Celsius, weigh the corresponding materials according to the formula and put them into the container;

[0023] (2) Measure 250-350 parts of sterile water into the container, use a glass rod to mix the ingredients into a paste;

[0024] (3) Take another 150-250 parts of sterile water and pour it into the pot. After heating to 60°C, weigh the agar and ethylparaben into the pot, increase the firepower to dissolve it, and then pour the paste. Use a glass rod to stir evenly throughout the whole process, turn to low heat after boiling in the pot, keep the temperature between 85-95°C, cook for 15-20 minutes and take it out;

[0025] (4) After cooking, cool to 60°C and pour into a sterilized container, use a feed p...

Embodiment 1

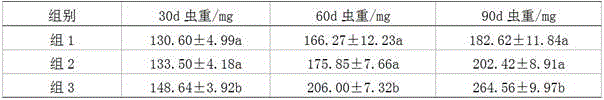

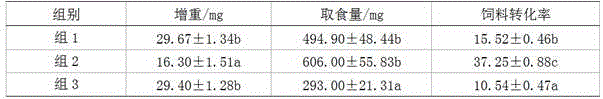

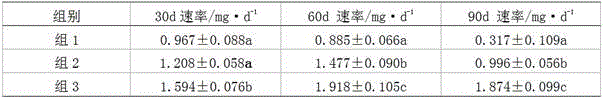

[0027] Indoor small-scale breeding of bat moth larvae in low-altitude areas, location: Ningde City, Fujian Province, time period: from February 19 to May 19, 2014, the 5th instar larvae of Menyuan bat moth were fed with artificial feed for a period of 90 days test. The weight of each ingredient per 1200g of feed is: 200g of wheat bran, 245g of fish meal, 50g of corn meal, 75g of soybean meal, 120g of Polygonum versicolor powder, and 125g of yeast meal. After the above components are sterilized by high-pressure steam, weigh them according to the formula and place them in a container, add 300g of sterile water and mix well to form a paste, and take another 20g of agar, 5g of ethylparaben and 200g of sterile water, Pour it into a pot and heat it to dissolve, then pour the paste into it, cook it slowly over low heat while stirring evenly, take it out after 20 minutes, cool it down to 60°C, pour it into a sterilized container, and press it with a feed pellet machine after condensat...

Embodiment 2

[0040] Indoor small-scale breeding of bat moth larvae in low-altitude areas, location: Ningde City, Fujian Province, time period: from February 19 to May 19, 2014, the 5th instar larvae of Menyuan bat moth were fed with artificial feed for a period of 90 days test. The weight of each ingredient per 1200g of feed is: 200g of wheat bran, 230g of fish meal, 60g of corn meal, 90g of soybean meal, 100g of Polygonum versicolor powder, and 110g of yeast meal. After the above components are autoclaved, place them in a container according to the formula, add 350g of sterile water and mix well to form a paste. Take another 20g of agar, 5g of ethylparaben and 250g of sterile water. Pour into a pot, heat to dissolve, pour in the paste and stir, cook slowly on low heat while stirring evenly, take it out after 15 minutes, cool to 60°C, pour into a sterilized container, and press it with a feed pellet machine after condensation Granules of 1.0g are prepared, and at the same time, small piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com