Preparation method of reduced graphite oxide-attapulgite composite aerogel

A technology of composite aerogel and attapulgite, which is applied in aerogel preparation, chemical instruments and methods, alkali metal compounds, etc. Agglomeration phenomenon, improve adsorption efficiency, increase the effect of internal channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

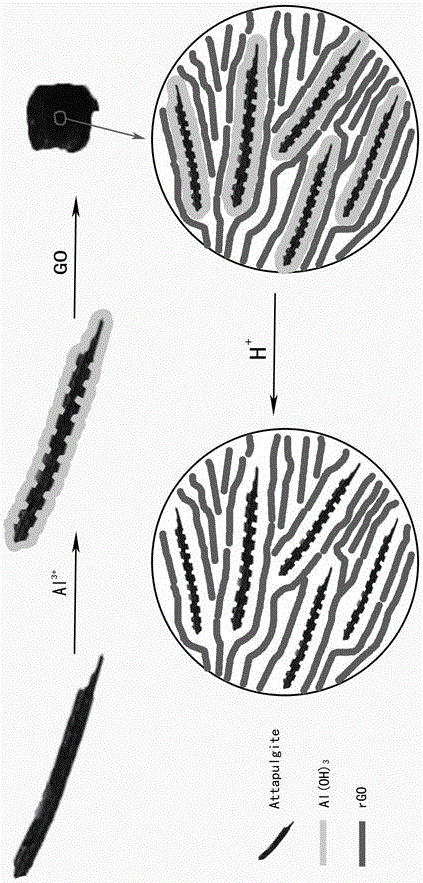

[0034] Step 1: Add 1g of attapulgite to 20mL of deionized water, sonicate for 1 hour, and stir for 1-5h; adjust the pH value to 4, according to the mass ratio of Al:attapulgite in the aluminum salt to 1:2-1:30 In the attapulgite colloid, drop the aluminum salt solution with a concentration of 2mol / L; in the process of dropping the aluminum salt solution, keep the pH value of the solution at 4-6, stir for 1h, adjust the pH value to 7, and stir for 1h , adjust the pH value to 9, stir for 1 hour, centrifuge, wash, and dry at 40°C for 5-12 hours to obtain attapulgite coated with aluminum hydroxide;

[0035] Step 2: Add aluminum hydroxide-coated attapulgite to 100mL graphite oxide dispersion with a concentration of 5mg / mL, sonicate for 5-30min, stir for 0.5-2h, pour the mixture into a hydrothermal reaction kettle, and heat at 100℃- Hydrothermal reaction in an oven at 180°C for 12 hours, cooled to room temperature, centrifuged, washed, and freeze-dried to obtain the attapulgite comp...

Embodiment 2

[0039] The preparation method of this example is basically the same as that of Example 1, except that the aluminum salt used is aluminum chloride, and the acid used to adjust the pH value is hydrochloric acid.

[0040] Using hydrochloric acid and aluminum chloride, the anions in the product are mainly chloride ions, which are easy to clean, easy to remove, and easy to detect.

Embodiment 3

[0042] The preparation method of this embodiment is basically the same as that of Example 2, except that the aluminum chloride solution is changed to a 2mol / L ferric chloride solution with the concentration of the same substance.

[0043] Both aluminum and iron ions of attapulgite have very good activation properties, and both can generate corresponding hydroxide protective layers on the surface, which can be removed by acid; in the treated wastewater, compared with aluminum ions, Iron ions are easier to recycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com