Intensified gold leaching method including strong magnetic separation and pre-removal of fine silt in gold-iron oxidized ore

A gold-iron oxidation and strong magnetic separation technology, which is applied in the field of enhanced gold leaching including strong magnetic separation to remove the fine mud in gold-iron oxide ore in advance, can solve the problems of low recovery rate, low grade, high production cost, etc. Achieve the effect of low production cost, reduced adsorption and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

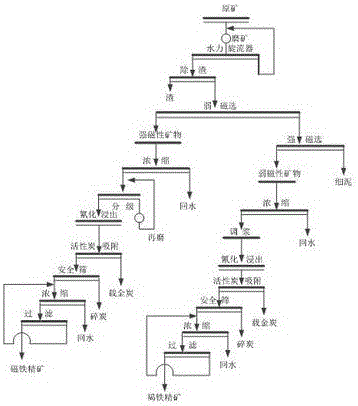

Image

Examples

Embodiment 1

[0038] In this embodiment, the ore feed is a certain iron-gold oxide ore in Yunnan, and the following steps are adopted to carry out the enhanced leaching of gold:

[0039] S1. After the raw ore is roughly ground by a ball mill and classified by a cyclone, the -0.074mm particle size accounts for 70%, and the FX75 cyclone is used for classification. Weak magnetic separation is carried out under the field strength to obtain strong magnetic minerals and weak magnetic separation tailings;

[0040]S2. The strong magnetic minerals obtained in step S1 are concentrated again, the concentrated return water is returned to the grinding and magnetic separation operation, and the concentrated pulp is classified, so that the -0.043mm particle size in the pulp accounts for 81%, and the particles of unqualified particle size enter Ball mill for regrinding. Add lime to the overflow of the cyclone to adjust the pH value of the slurry to 11, the concentration of the slurry is 25%, add sodium cy...

Embodiment 2

[0046] In this embodiment, the ore feed is a certain iron-gold oxide ore in Sichuan, and the following steps are adopted to carry out the enhanced leaching of gold:

[0047] S1. After the raw ore is roughly ground by a ball mill and classified by a spiral classifier, the -0.074mm particle size accounts for 75%; the spiral classifier is used for the classification operation, and the classifier overflows and removes slag in a field strength of 0.3T. Weak magnetic separation is carried out under the environment to obtain strong magnetic minerals and tailings of weak magnetic separation;

[0048] S2. The strong magnetic minerals obtained in step S1 are concentrated again, and the concentrated return water is returned to the grinding and magnetic separation operation, and the concentrated pulp is classified, so that the -0.043mm particle size in the pulp accounts for 85%, and the particles of unqualified particle size enter Ball mill for regrinding. Add lime to the overflow of the...

Embodiment 3

[0053] In this embodiment, the ore feed is a certain iron-gold oxide ore in Guangxi, and the method of following steps is adopted to carry out the enhanced leaching of gold:

[0054] S1. After the ore is roughly ground by a ball mill and classified by a spiral classifier, the particle size of -0.074mm accounts for 80%. The spiral classifier is used for the classification operation. Weak magnetic separation is carried out under strong pressure to obtain strong magnetic minerals and tailings of weak magnetic separation;

[0055] S2. The strong magnetic minerals obtained in step S1 are concentrated, and the concentrated return water is returned to the grinding and magnetic separation operation, and the concentrated pulp is classified, so that the -0.043mm particle size in the pulp accounts for 85%, and the unqualified particles enter the ball mill Regrind. Add lime to the overflow of the cyclone to adjust the pH value of the slurry to 11, the concentration of the slurry is 23%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com