Half-metallic bismuth nanoribbon, half-metallic bismuth nanospheres and preparation method of half-metallic bismuth nanoribbon and half-metallic bismuth nanospheres

A bismuth nano and semi-metal technology, applied in the field of nanobelts and nanospheres and their preparation, to achieve the effect of less links, less experimental links, and less experimental raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

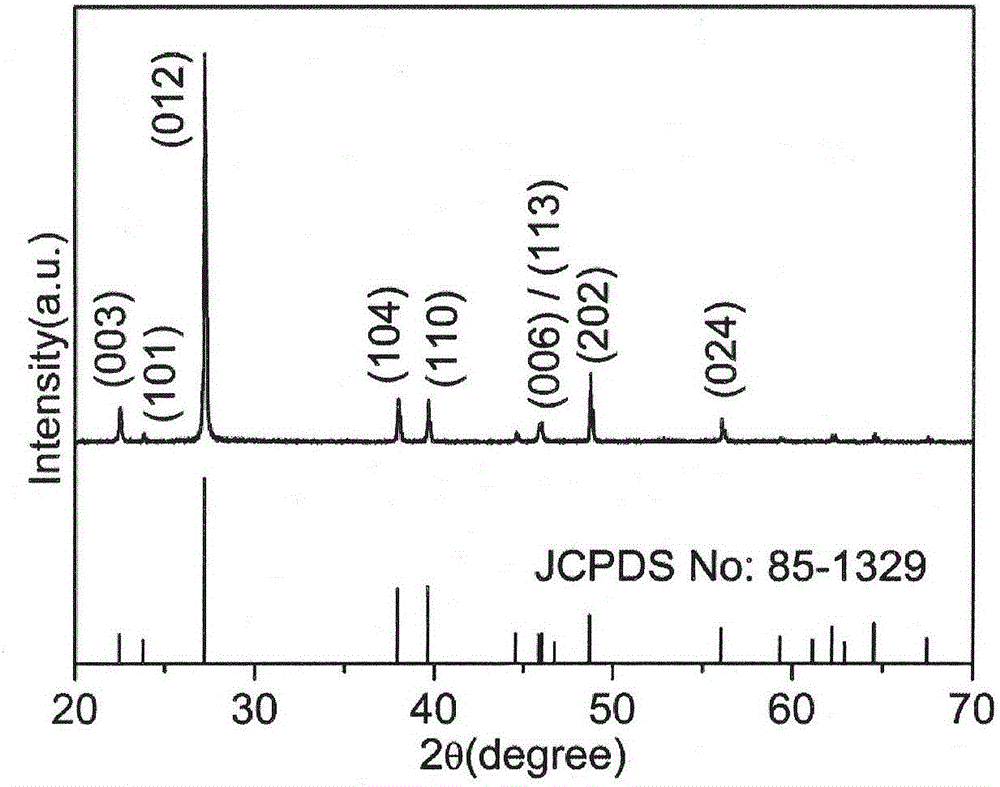

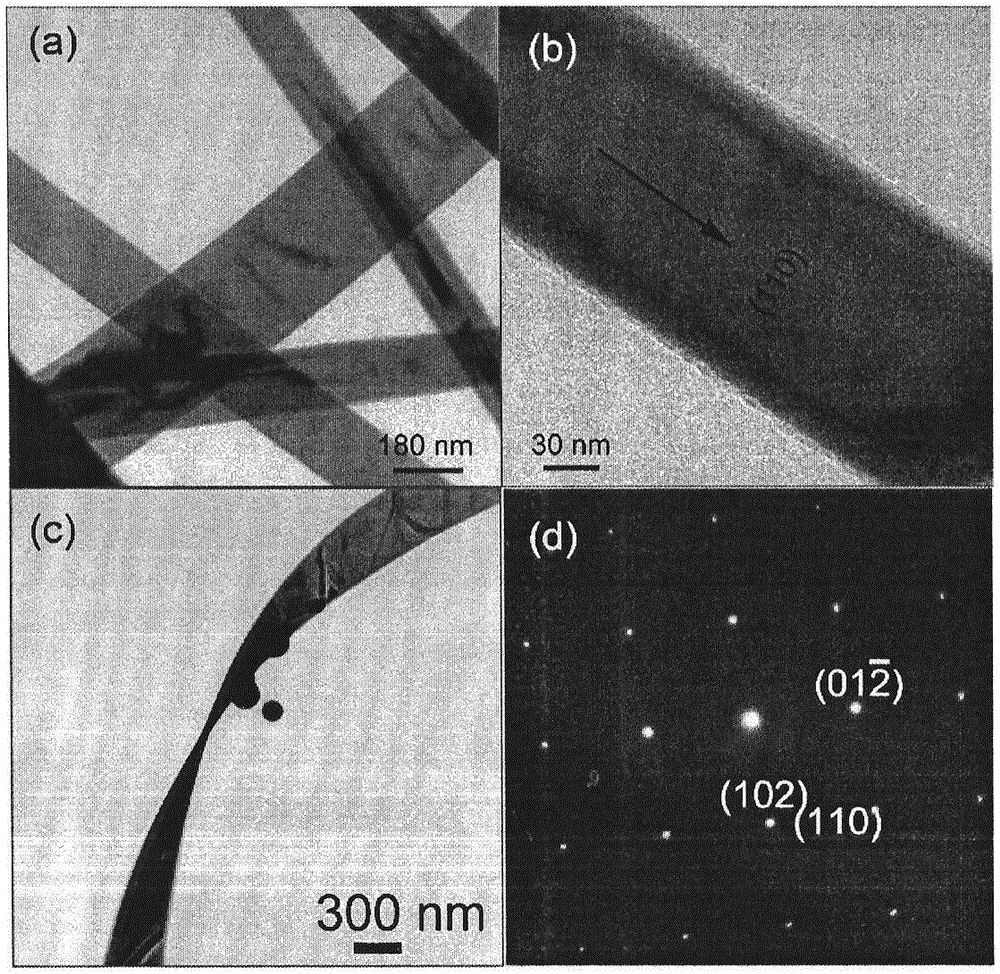

[0020] Embodiment 1: Get 0.15g bismuth chloride and put into 30ml glycerin, magnetically stir 40min to make it mix evenly, use N 2 Blow the air for 10 minutes to remove the dissolved oxygen in the liquid. The prepared solution was transferred into the liner of the autoclave, and put into a blast drying oven for reaction, the reaction temperature was 200° C., and the reaction time was 12 hours. After the reaction was completed, it was cooled with the furnace, and the reactant was taken out, washed several times with absolute ethanol, filtered through a 450nm organic filter membrane, then dried under vacuum at low temperature, and samples were collected. Observation and testing are performed on the prepared sample using a scanning electron microscope and an X-ray diffractometer, according to X-ray diffraction (XRD) ( figure 1 ), where the ordinate is the relative intensity, and the abscissa is the diffraction angle. From the position and relative intensity of each diffraction p...

Embodiment 2

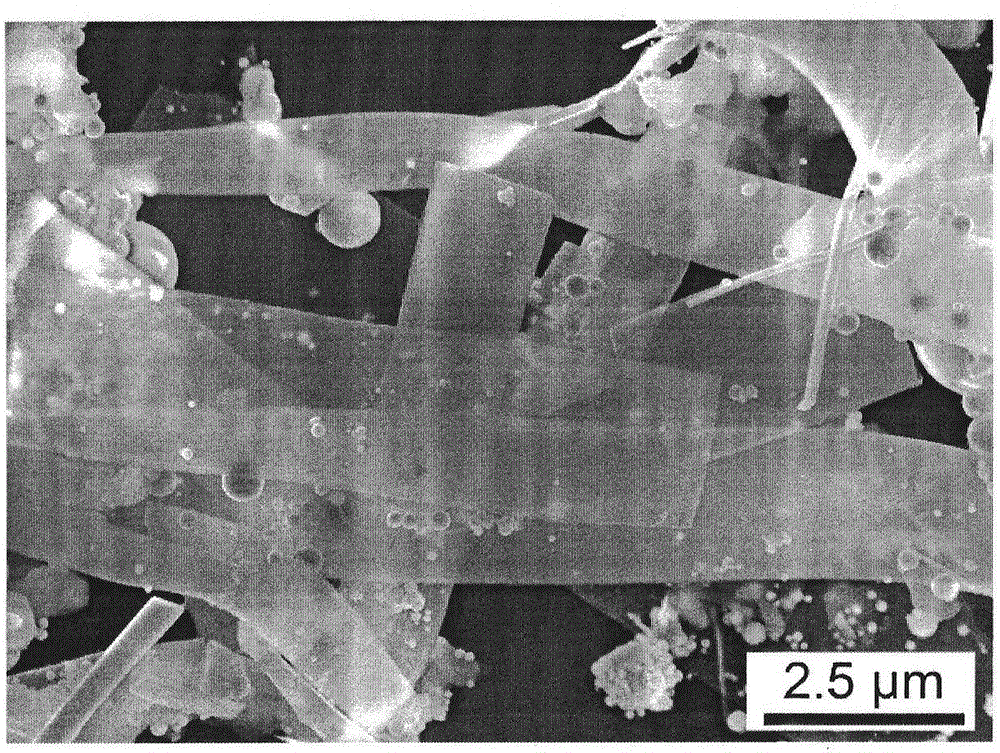

[0021] Embodiment 2: get 0.3g sodium nitrate and put into 40ml ethylene glycol, magnetic stirring 40min makes it mix evenly, with N 2 Blow the air for 10 minutes to remove the dissolved oxygen in the liquid. The prepared solution was transferred into the liner of the autoclave, and put into a blast drying oven for reaction, the reaction temperature was 150° C., and the reaction time was 24 hours. After the reaction was completed, it was cooled with the furnace, and the reactant was taken out, washed several times with absolute ethanol, filtered through an 800nm organic filter membrane, then dried at low temperature under vacuum, and samples were collected. The prepared samples were observed and tested with a scanning electron microscope and an X-ray diffractometer. According to the X-ray diffraction (XRD) results, the prepared samples were pure bismuth. According to the scanning electron microscope (SEM) ( Figure 4 ), indicating the successful preparation of semimetallic ...

Embodiment 3

[0022] Embodiment 3: Get 0.15g sodium bismuthate and put it into 30ml glycerin, magnetically stir it for 40min to make it mix evenly, use N 2 Blow the air for 10 minutes to remove the dissolved oxygen in the liquid. The prepared solution was transferred into the liner of the autoclave, and put into a blast drying oven for reaction, the reaction temperature was 220° C., and the reaction time was 10 hours. After the reaction was completed, it was cooled with the furnace, and the reactant was taken out, washed several times with cyclohexane, filtered through a 1.2 μm organic filter membrane, then dried under vacuum at low temperature, and samples were collected. Observation and testing are performed on the prepared sample using a scanning electron microscope and an X-ray diffractometer, according to X-ray diffraction (XRD) ( figure 1 ), where the ordinate is the relative intensity, and the abscissa is the diffraction angle. From the position and relative intensity of each diffra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com