A kind of preparation method of stannous fluoride

A technology of stannous fluoride and tin dioxide, applied in tin halide and other directions, can solve the problems of equipment corrosion, low productivity and low purity, and achieve the effects of easy low temperature condensation and solidification, easy high temperature volatilization, and low raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

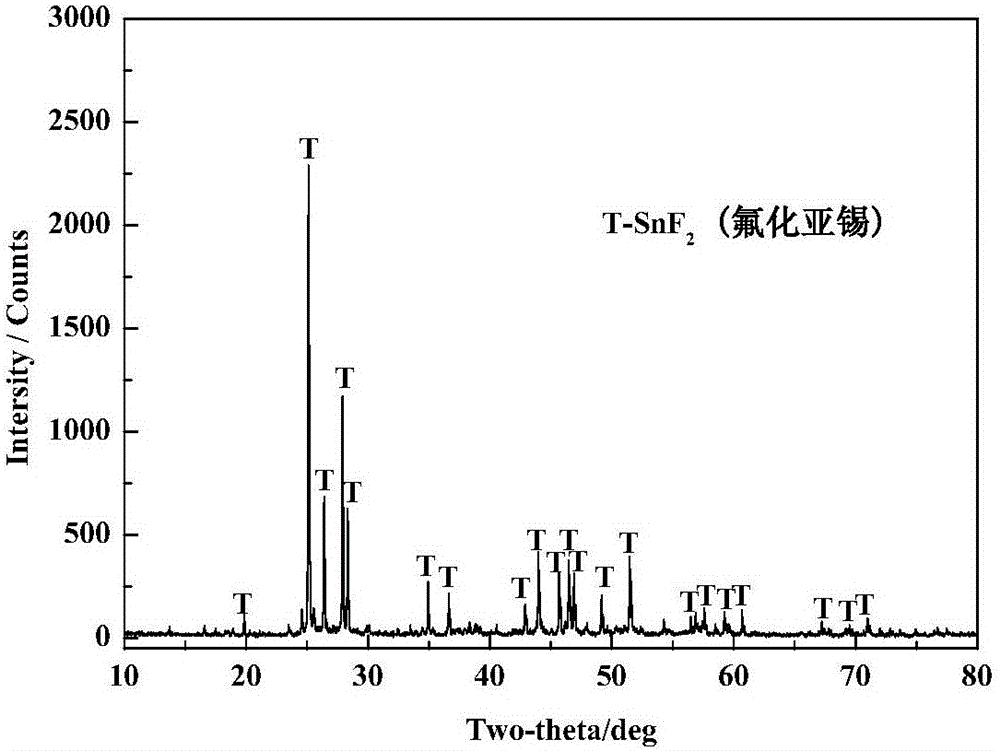

Image

Examples

Embodiment 1

[0024] To analyze pure SnO 2 (purity 99.5%), CaF 2 (purity 99.5%) and CMC as raw materials are respectively ground to -0.074mm particle size and the mass percentage is not less than 80%; the analytically pure SnO after pretreatment 2 , CaF 2 , CMC according to SnO 2 :CaF 2 : The molar ratio of CMC is 1:1:0.2 and mixed evenly; put the mixed powder material into CO and CO 2 Composition of the roasting atmosphere heating and roasting, the roasting temperature is 500 ° C, the roasting atmosphere is [CO / (CO+CO 2 )] is 50%, the roasting time is 60min, and the high-purity stannous fluoride product is recovered from its separation and recovery from the roasting tail gas smoke dust, and the analysis product SnF 2 The content is 96.7%, SnF 2 Yield 75.6%.

Embodiment 2

[0026] To analyze pure SnO 2 (purity 99.5%), CaF 2 (purity 99.5%) and CMC as raw materials are respectively ground to -0.074mm particle size and the mass percentage is not less than 80%; the analytically pure SnO after pretreatment 2 , CaF 2 , CMC according to SnO 2 :CaF 2 : The CMC molar ratio is 1:1.2:0.1 and mixed evenly; put the mixed powder material into CO and CO 2 Composition of the roasting atmosphere heating and roasting, the roasting temperature is 1000 ℃, the roasting atmosphere is [CO / (CO+CO 2 )] is 23%, the roasting time is 80min, and the high-purity stannous fluoride product is recovered from its separation and recovery from the roasting tail gas smoke dust, and the analysis product SnF 2 The content is 96.0%, SnF 2 Yield 85.6%.

Embodiment 3

[0028] To analyze pure SnO 2 (purity 99.5%), fluorite concentrate (CaF 2 Theoretical content 87.3%) and CMC as raw materials are respectively ground to -0.074mm particle size and the mass percentage is not less than 80%; the analytically pure SnO after pretreatment 2 , fluorite concentrate, CMC according to SnO 2 :CaF 2 : The CMC molar ratio is 1:1.2:0.13 and mixed evenly; put the mixed powder material into CO and CO 2 Composition of the roasting atmosphere heating and roasting, the roasting temperature is 750 ° C, the roasting atmosphere is [CO / (CO+CO 2 )] is 5%, the roasting time is 100min, and the high-purity stannous fluoride product is recovered from the roasting tail gas smoke dust, and the analysis product SnF2 96.2% pure, SnF 2 Yield 88.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com