Silane coupling agent Si-75 synthetic method for improving yield

A technology of silane coupling agent and synthesis method, which is applied in the field of silane coupling agent, can solve the problems of short storage time of finished products, low product purity, low conversion rate of raw materials and low yield of products, etc., so as to improve the conversion rate of raw materials and improve the quality of products. Purity, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

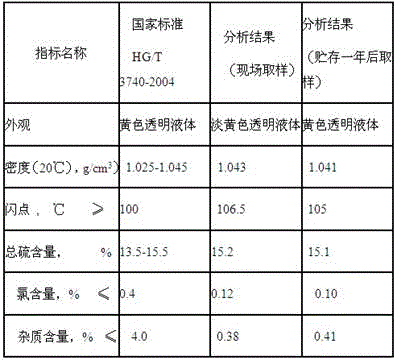

Examples

Embodiment 1

[0032] Embodiment 1 A kind of silane coupling agent Si-75 synthetic method that improves yield

[0033] Include the following steps:

[0034] Step 1, prepare sodium disulfide

[0035] (1) Add raw materials

[0036] Add 100Kg of low-iron sodium sulfide and 20.8Kg of elemental sulfur into the double-cone drying reactor;

[0037] (2) The first stage reaction

[0038] Start the rotary switch of the drying reactor to make it run, turn on the water ring vacuum pump, and when the vacuum degree in the dryer reaches 0.082Mpa and is stable, feed steam into the jacket of the drying reactor, and adjust the steam pressure to 0.2-0.3Mpa. When the temperature in the drying reactor reaches 50°C, properly adjust the opening of the steam valve;

[0039] (3) The second stage reaction

[0040] Control the temperature in the drying reactor to 60-65°C, start timing since the temperature in the drying reactor reaches 60°C, and react for 1 hour;

[0041] (4) The third stage reaction

[0042] S...

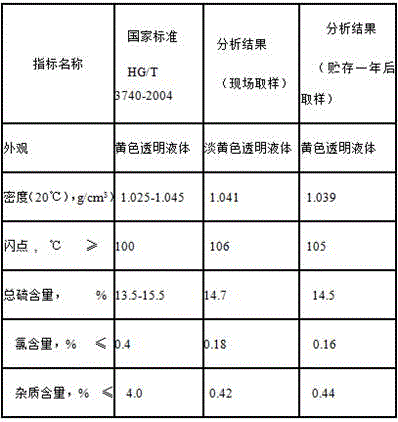

Embodiment 2

[0065] Embodiment 2 A kind of silane coupling agent Si-75 synthetic method that improves yield

[0066] Step 1, prepare sodium disulfide

[0067] (1) Add raw materials

[0068] Add 101.5Kg of low-iron sodium sulfide and 21.2Kg of elemental sulfur into the double-cone drying reactor;

[0069] (2) The first stage reaction

[0070] Start the rotary switch of the drying reactor to make it run, turn on the water ring vacuum pump, and when the vacuum degree in the dryer reaches 0.082Mpa and is stable, feed steam into the jacket of the drying reactor, and adjust the steam pressure to 0.2-0.3Mpa. When the temperature in the drying reactor reaches 50°C, properly adjust the opening of the steam valve;

[0071] (3) The second stage reaction

[0072] Control the temperature in the drying reactor to 65-70°C, start timing since the temperature in the drying reactor reaches 65°C, and react for 1 hour;

[0073] (4) The third stage reaction

[0074] After one hour, switch the vacuum, fir...

Embodiment 3

[0097] Embodiment 3 A kind of silane coupling agent Si-75 synthetic method that improves yield

[0098] Include the following steps:

[0099] Step 1, prepare sodium disulfide

[0100] (1) Add raw materials

[0101] Add 108.8Kg of low-iron sodium sulfide and 22Kg of elemental sulfur to the double-cone drying reactor;

[0102] (2) The first stage reaction

[0103] Start the rotary switch of the drying reactor to make it run, turn on the water ring vacuum pump, and when the vacuum degree in the dryer reaches 0.082Mpa and is stable, feed steam into the jacket of the drying reactor, and adjust the steam pressure to 0.2-0.3Mpa. When the temperature in the drying reactor reaches 50°C, properly adjust the opening of the steam valve;

[0104] (3) The second stage reaction

[0105] Control the temperature in the drying reactor to 60-65°C, start timing since the temperature in the drying reactor reaches 60°C, and react for 1 hour;

[0106] (4) The third stage reaction

[0107] Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com