Method for preparing polymer-based composite material with high dielectric constant

A technology of high dielectric constant and composite materials, which is applied in the field of preparing polymer matrix composite materials with high dielectric constant, can solve the problem of reduced mechanical properties and heat dissipation properties of composite materials, limited increase in dielectric constant, poor matrix interface, etc. problems, to achieve the effect of promoting mutual penetration and diffusion, excellent mechanical properties, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

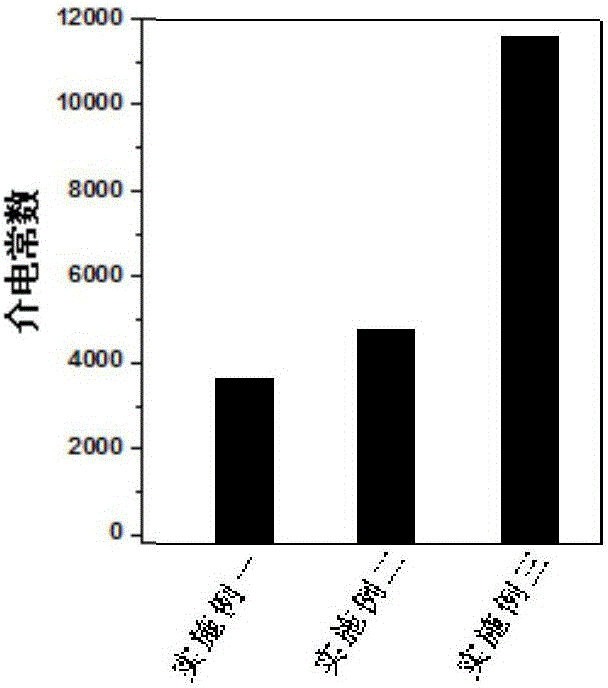

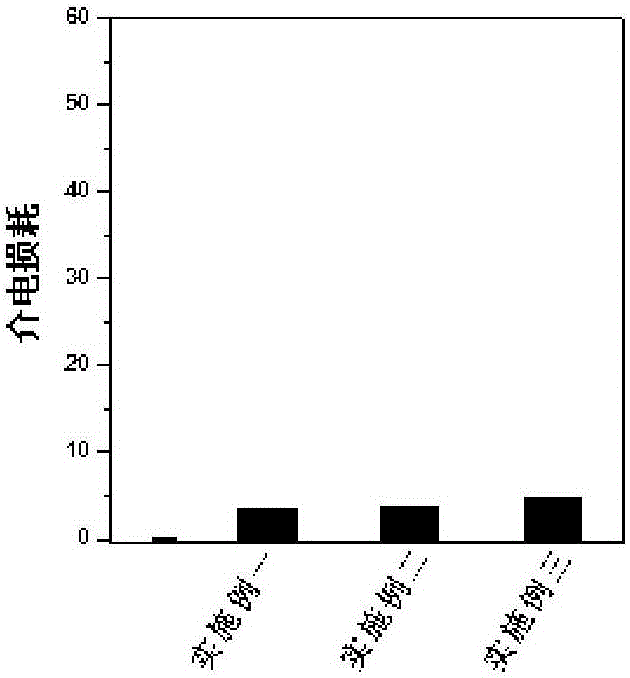

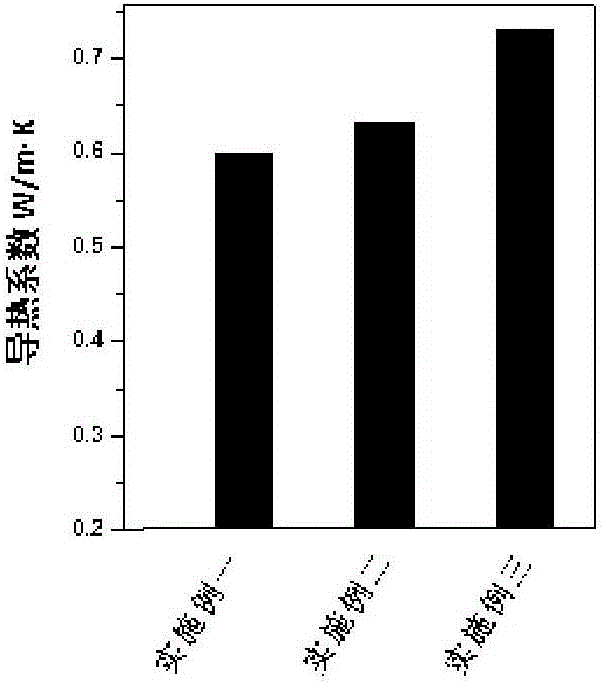

Embodiment 1

[0030] A method for preparing a polymer-based composite material with a high dielectric constant, the steps of which are as follows:

[0031] A. Preparation of masterbatch by solution blending: Dissolve 100 parts by weight of polyvinylidene fluoride in N,N-dimethylformamide to obtain solution 1; the temperature during dissolution is 55°C, the dissolution time is 20 minutes, and with Stirring, the stirring rate is 50r / min.

[0032] Ultrasonic disperse 10 parts by weight of hexagonal boron nitride with a sheet diameter of 3-5 μm in N,N-dimethylformamide to obtain solution 2; the temperature during ultrasonic dispersion is 55°C, the ultrasonic time is 2 hours, and the ultrasonic power 100W.

[0033] Disperse 1.6 parts by weight of single-walled carbon nanotubes with a diameter of 0.5nm and a length of 10-30μm in N,N-dimethylformamide to obtain solution 3; the temperature during dispersion is 55°C

[0034] Then, solution 1, solution 2 and solution 3 were mixed and subjected to u...

Embodiment 2

[0038] A method for preparing a polymer-based composite material with a high dielectric constant, the steps of which are as follows:

[0039] A. Preparation of masterbatch by solution blending: Dissolve 100 parts by weight of polyvinylidene fluoride in N,N-dimethylformamide to obtain solution 1; the temperature during dissolution is 70°C, the dissolution time is 30 minutes, and with Stirring, the stirring rate is 80r / min.

[0040] Ultrasonic disperse 10 parts by weight of hexagonal boron nitride with a sheet diameter of 3-5 μm in N,N-dimethylformamide to obtain solution 2; the temperature during ultrasonic dispersion is 70°C, the ultrasonic time is 3 hours, and the ultrasonic power It is 80W.

[0041] Disperse 1.8 parts by weight of multi-walled carbon nanotubes with a diameter of 100nm and a length of 10-30μm in N,N-dimethylformamide to obtain solution 3; the temperature during dispersion is 70°C

[0042] Then, solution 1, solution 2 and solution 3 were mixed and subjected ...

Embodiment 3

[0046] A method for preparing a polymer-based composite material with a high dielectric constant, the steps of which are as follows:

[0047] A. Preparation of masterbatch by solution blending: Dissolve 100 parts by weight of polyvinylidene fluoride in N,N-dimethylformamide to obtain solution 1; the temperature during dissolution is 80°C, the dissolution time is 40 minutes, and with Stirring, the stirring rate is 100r / min.

[0048] Ultrasonic disperse 10 parts by weight of hexagonal boron nitride with a sheet diameter of 3-5 μm in N,N-dimethylformamide to obtain solution 2; the temperature during ultrasonic dispersion is 80°C, the ultrasonic time is 4 hours, and the ultrasonic power 100W.

[0049] Disperse 2 weights of multi-walled carbon nanotubes with a diameter of 200nm and a length of 10-30μm in N,N-dimethylformamide to obtain solution 3; the temperature during dispersion is 80°C

[0050] Then, solution 1, solution 2 and solution 3 were mixed and subjected to ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com