Nano-TiO2 adopting core-shell structure for white high-covering-power pigment and preparation method of nano-TiO2

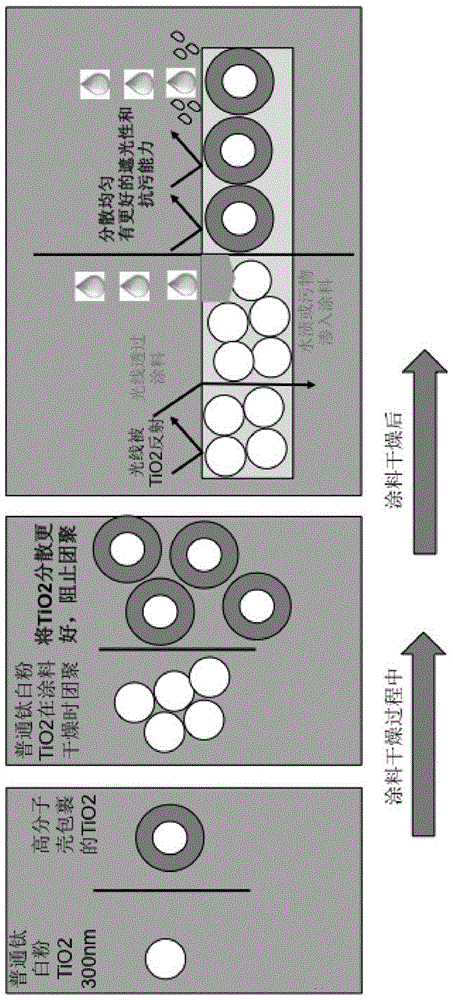

A nano-titanium dioxide, core-shell structure technology, applied in chemical instruments and methods, inorganic pigment treatment, dyed polymer organic compound treatment, etc. It can improve the shading performance, shorten the preparation time and reduce the dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A specific example of a core-shell structure nano-titanium dioxide used for high-hiding white pigments and a preparation method thereof according to the present invention, the titanium dioxide nano-particles of the titanium dioxide composite material are in the form of a hard polymer shell wrapped with high-molecular titanium The core-shell structure of the white powder nanoparticle core, the polymer adopts lactic acid, glycolic acid, caprolactone, styrene, C4-C8-alkyl acrylate, C4-C8-alkyl methacrylate, or -alkylaryl ester A polymer composed of copolymers that are monomer units. Its preparation comprises the following steps:

[0013] ①Using titanium dioxide or titanium dioxide as the raw material, the titanium dioxide that is insoluble in the oil phase is dispersed into the oil phase solvent in which the polymer material is dissolved by the double emulsification method, and mixed and stirred to form an oil-in-oil solid particle emulsion; the oil phase solvent Organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com