Outer wall for prefabricated wallboard and steel structure assembling

A prefabricated assembly and wall panel technology, applied in truss structures, walls, building components, etc., can solve problems such as poor controllability, environmental pollution, loss of energy-saving and thermal insulation functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be further described below in conjunction with the accompanying drawings.

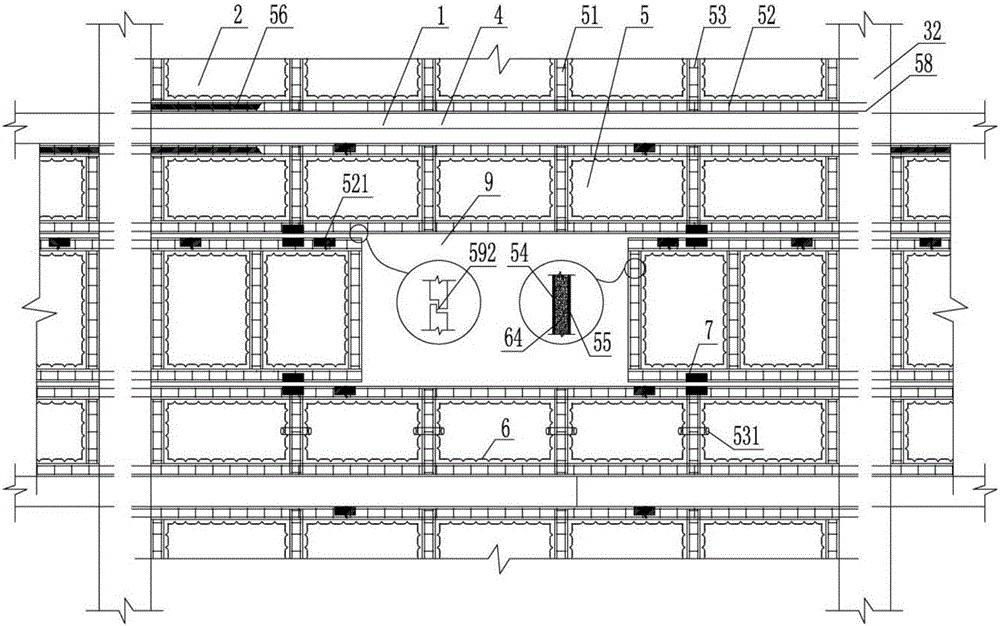

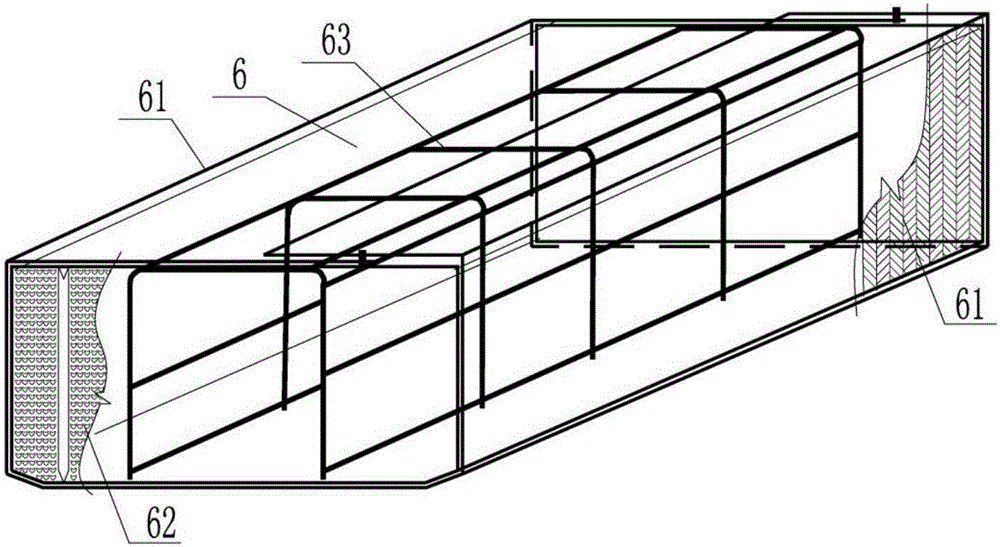

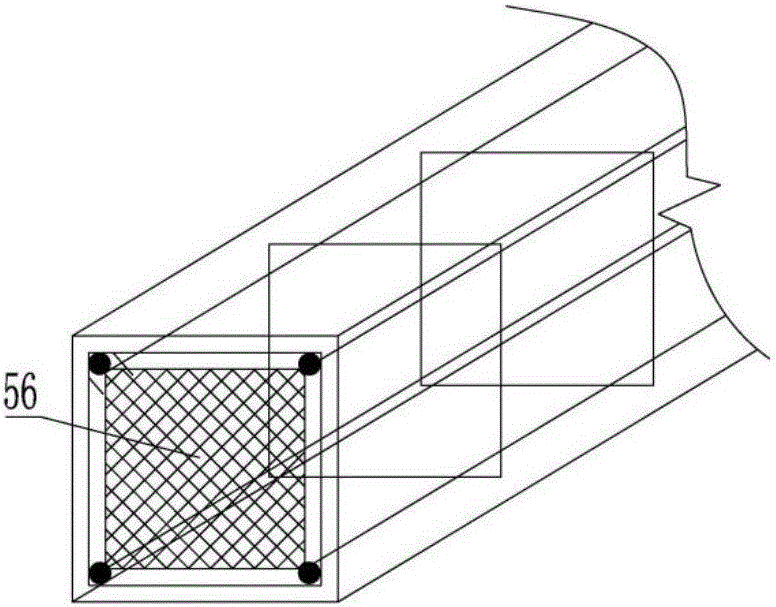

[0021] figure 1It is a plan view of the outer wall body of the combination of prefabricated assembled wallboard and steel structure of the present invention. When the present invention is implemented, the prefabricated assembled wallboard component 2 produced in the factory assembly line is hoisted to the installation site of the steel column 32, and the prefabricated assembled wallboard component 2 is lifted to the installation site of the steel column 32. Some components 2 and exposed rib steel bars 58 of the prefabricated wall panel component 2 are embedded in the steel column 32 and welded on site; The adjacent joints of the two components 2 are set as willows 592 or slopes 591 to prevent the rainwater from the outer wall from infiltrating into the room through the joints; the adjacent joints of the two components 2 are pre-buried with a small poly to make the ribs and ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com