Graphene-polypyrrole nanoparticle composite film electrode and preparation method thereof

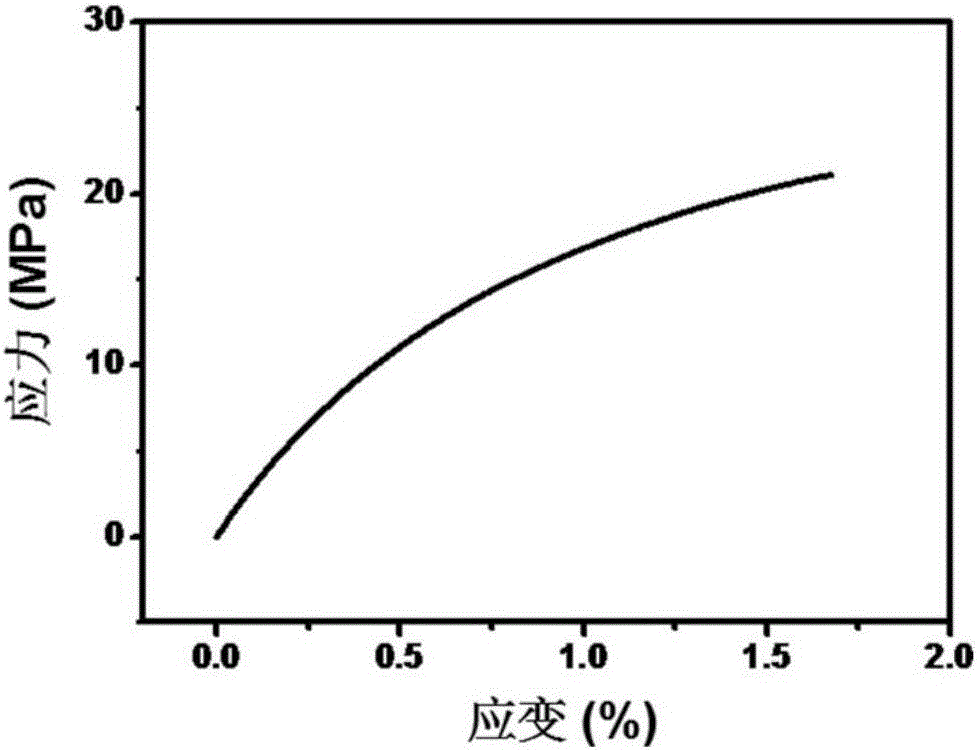

A polypyrrole nano-particle composite technology, which is applied in the field of electrochemical energy storage, can solve the problems of affecting electrochemical performance, poor conductivity of metal oxides, poor mechanical properties of graphene hydrogel film electrodes, etc., and achieve good mechanical properties and The effect of electrochemical performance, simple preparation method, and easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

[0023] In a preferred embodiment of the present invention, the preparation of the reduced graphene oxide solution in step A can be achieved by the following steps: Weigh 600 mg of graphene oxide prepared by the Hummers method and disperse it in deionized water, add 1.5 g of dodecyl Sodium benzenesulfonate was used as a surfactant, and the graphene oxide dispersion was obtained by ultrasonication for 1 h; 3 mL of 85% hydrazine hydrate was added, and the oil bath was heated to 100 ° C, and the reduced graphene oxide dispersion was obtained after 12 h of reaction. The concentration of the reduced graphene oxide dispersion obtained in this example can be adjusted to 0.6 mg / mL by further adding deionized water.

Embodiment B1

[0025] In a preferred embodiment of the present invention, the preparation of polypyrrole nanoparticles in step B can be achieved through the following steps: 0.676gFeCl 3 ·6H 2 O was dissolved in 50 mL of water, 0.818 g of methyl orange was added, stirred for 0.5 h, 0.168 g of pyrrole monomer was added, stirred at room temperature for 24 h, solid-liquid separation, and vacuum-dried at 60°C for 24 h to obtain polypyrrole nanoparticle solid powder.

Embodiment C1

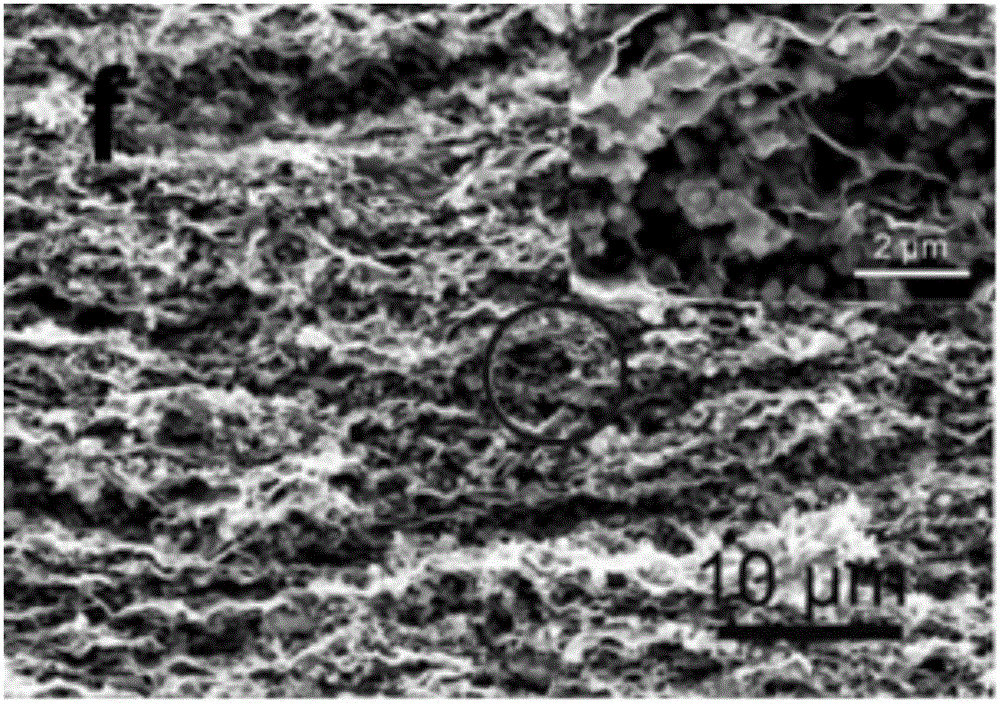

[0027] In a preferred embodiment of the present invention, the preparation of the graphene-polypyrrole nanoparticle composite film in step C can be achieved by the following steps: take the above-mentioned reduced graphene oxide dispersion 45mL, add 3mg of the above-mentioned polypyrrole nanoparticles, ultrasonic 0.5 h, filter under reduced pressure, dry naturally, and remove the filter membrane to obtain a graphene-polypyrrole nanoparticle composite film.

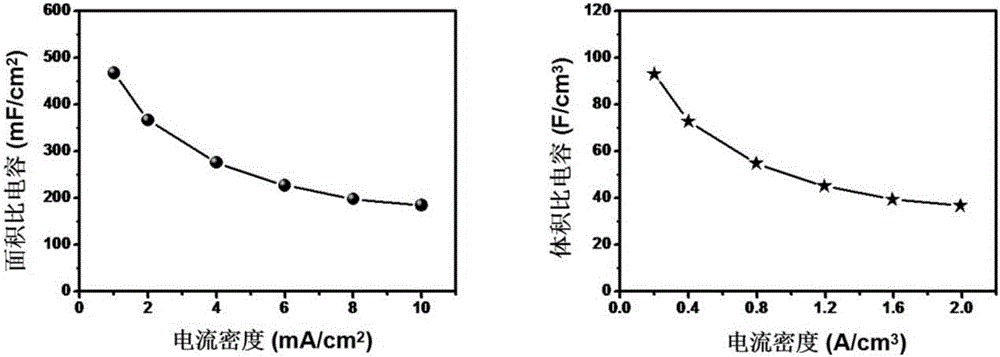

[0028] The graphene-polypyrrole nanoparticle composite film that present embodiment obtains contains the polypyrrole nanoparticle of 10wt%, and thickness is 39.4 μm, and area density is 2.96mg / cm 2 . Electrochemical tests were carried out under the three-electrode system, and the maximum area specific capacitance of the graphene-polypyrrole nanoparticle composite film electrode was 232mF / cm 2 , the maximum volume specific capacitance is 58.7F / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com