Lithium ion battery composite material and preparation method thereof, and positive electrode material including composite material

A technology of lithium-ion batteries and composite materials, which is applied in the field of positive electrode materials, batteries, and lithium-ion battery composite materials. The effect of depth and charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

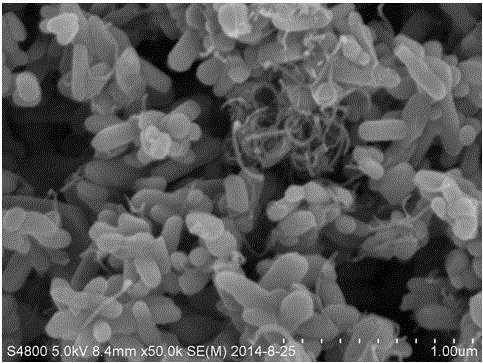

Image

Examples

preparation example Construction

[0022] This application also proposes a preparation method for lithium -ion battery composite materials, including:

[0023] (1) Mixing the lithium source, phosphorus source, and iron source according to measurement ratio, the reaction to get the front -drive A, the reaction temperature is 105 ~ 130 ° C, and the response time is 1 ~ 30min;

[0024] (2) Mix the lithium source, phosphorus source, railway source, manganese source according to measurement, and react with the front drive A to get the front -drive B, the reaction temperature is 105 ~ 120 ° C, and the response time is 1 ~ 30min;

[0025] (3) Mix the lithium sources, phosphorus sources, and iron sources with the front -drive body B, and wash the reaction product and dry the core of the core as the lithium iron phosphate, the outer nucleus is manganese -phosphate iron lithium, and the shell layer is a composite material for lithium iron phosphate.The reaction temperature is 160 ~ 220 ° C, and the reaction time is 2 ~ 30 mi...

Embodiment 1- Embodiment 5

[0035] Example 1-Example 5: Preparation of Lithium-ion battery composite materials.

Embodiment 1

[0037] (1) Under the protection of nitrogen, the concentration of 0.25 mol / L sulfate sulfate solution, and the concentration of 0.5 mol / L phosphate solution, then add the phosphate solution to the sulfate solution to form a mixed solution, and then add 5g of antimediaHybrid solution E1.Under the protection of nitrogen, the formulation concentration is 0.750mol / L lithium hydroxide F1 solution.In the stirring state, add the lithium hydroxide solution F1 to the mixed solution E1. During the mixing process, the emulsifier is mixed to obtain a front drive A containing phosphorus, iron, and lithium. Among them, li: Fe: P = 3: 0.98: 1.

[0038] (2) Under the protection of nitrogen, it is called 2335.32g sulfate and 2637.02g manganese sulfate to remove ionic water to make a mixed solution.A mixed solution is formed, and then 10g of antibody acid is added to form a hybrid solution E2.Under the protection of nitrogen, the preparation concentration is 2.88mol / L lithium hydroxide solution F2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com