Wet type electric dust collector with pre-coagulation function

A wet electrostatic precipitator, functional technology, applied in the field of deep purification of flue gas, can solve the problem of low dust removal efficiency of ultrafine dust particles, achieve the effect of simple and light structure, stable secondary value, and improved wet removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

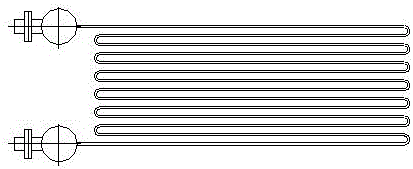

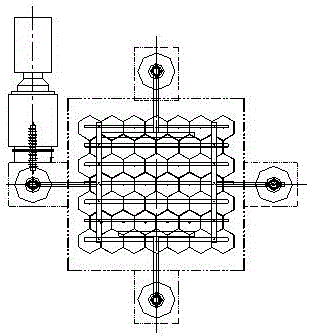

[0032] Such as figure 1 As shown, the wet electrostatic precipitator with pre-condensation function of the present invention is arranged on the top of the desulfurization absorption tower (only the top structure of the absorption tower is shown in the figure), mainly including the wet electrostatic precipitator, the condensation heat exchanger 1, and the external water tank 8 and sprinklers. The wet electrostatic precipitator is set above the condensing heat exchanger 1. The wet electrostatic precipitator is mainly composed of the cathode lower frame 2, the cathode wire 3, the cathode upper frame 4, the cathode suspension 5 and the anode assembly 7. The condensing heat exchanger 1 Installed between the outlet of the absorption tower mist eliminator and the wet electrostatic precipitator, and above the wet electrostatic precipitator and the condensing heat exchanger are respectively equipped with a flushing device, and the flushing device includes a flushing nozzle and a spray ...

Embodiment 2

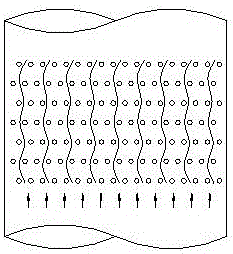

[0038] The alumina catalyst used in the petroleum refining industry is manufactured by high-temperature roasting process. During the manufacturing process, a small amount of alumina powder will escape. The alumina powder cannot be charged and the particle size is less than 10 microns. The flue gas directly enters the wet electrostatic precipitator. Due to the limitation of alumina's own characteristics, the dust removal efficiency can only reach 30-50%. However, after the flue gas passes through the wet electrostatic precipitator with a condensing heat exchanger of the present invention, the temperature of the flue gas drops by 1 to 3°C, and the gas phase water condenses and precipitates into mist droplets, and the porous alumina powder condenses with it, and not only the particle size Increased to more than 40 microns, and the charging performance is improved dozens of times due to the condensed water wrapped on the surface. The condensed alumina powder particles are quickly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inscribed circle diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com