Tanning synthetic wastewater treatment system and treatment method

A technology for treating system and comprehensive wastewater, applied in animal processing wastewater treatment, special compound water treatment, multi-stage water treatment, etc., can solve the problems of effluent COD not being able to meet the standard stably, effluent TN not being able to meet the standard discharge stably, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

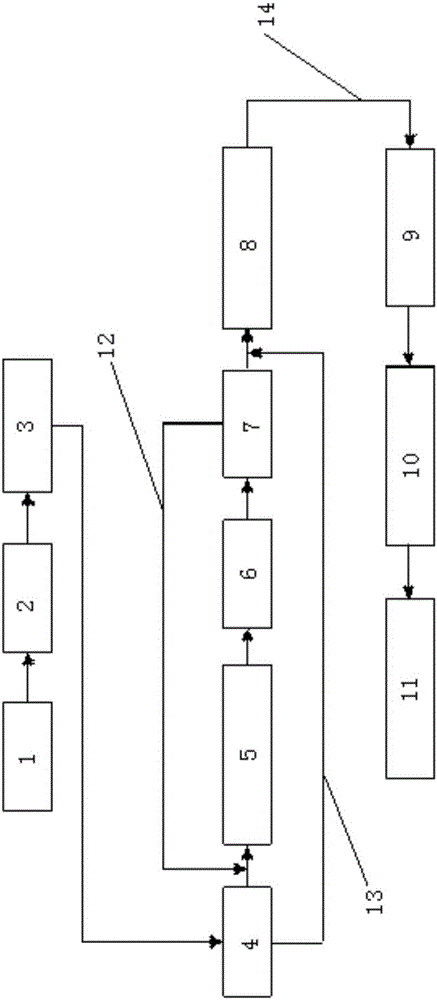

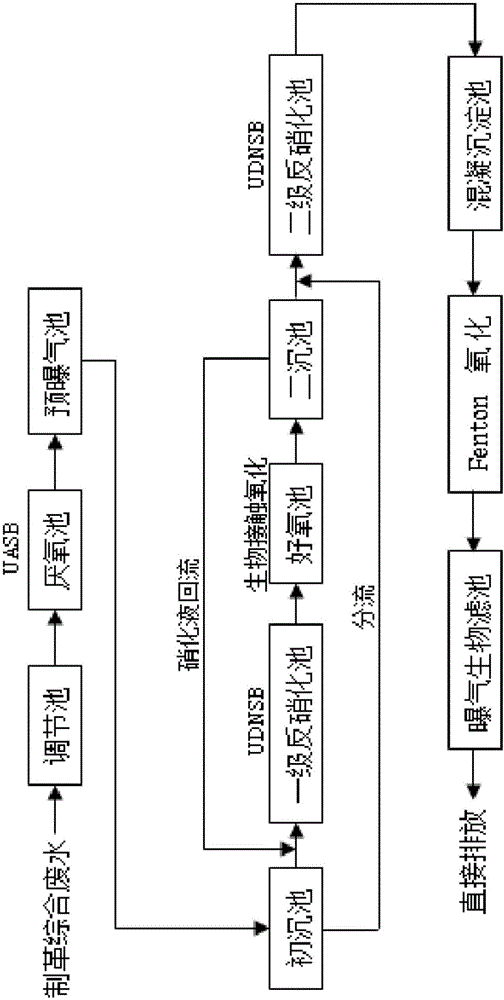

Method used

Image

Examples

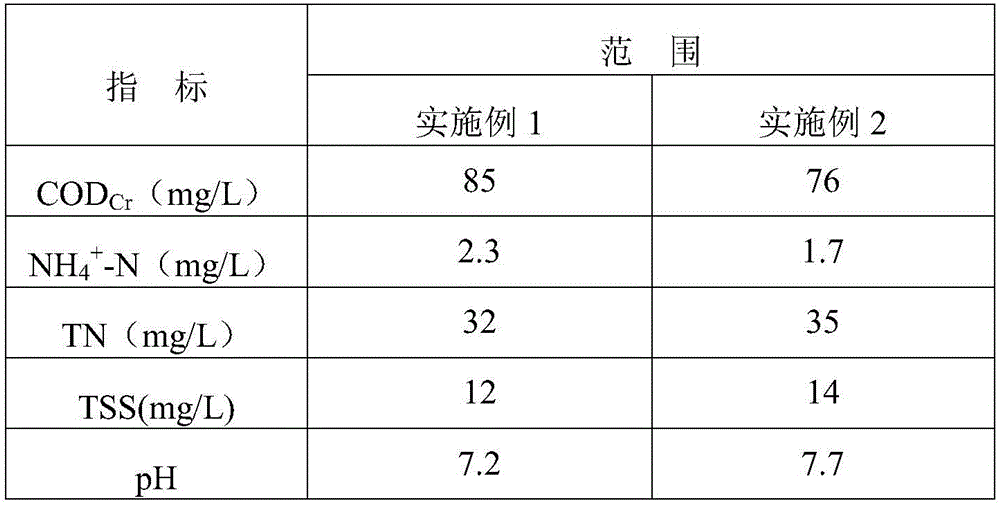

Embodiment 1

[0174] 1. Wastewater pretreatment

[0175] The tannery comprehensive wastewater from a sewage plant in a tannery area in Hebei Province was introduced into the regulating tank, and the acidic regulator sulfuric acid was added at the same time, and stirred evenly, so that the pH of the wastewater in the regulating pond was 7; and the alkali regulating agent (bicarbonate Sodium), the alkalinity is supplemented to 1000mg / L, and the mixer stirs evenly;

[0176] 2. Anaerobic treatment

[0177] By connecting the pipeline and the sewage pump installed on the pipeline, the pretreated and mixed wastewater in the regulating tank is introduced into the anaerobic tank for anaerobic treatment, and the hydraulic retention time in the anaerobic tank is controlled to 10h, so that the concentration of volatile fatty acids in the effluent of the anaerobic tank is ≤ 800mg / L;

[0178] 3. Pre-aeration treatment

[0179] Pass the effluent after anaerobic treatment into the pre-aeration tank thro...

Embodiment 2

[0200] 1. Wastewater pretreatment

[0201] The tannery comprehensive wastewater from a sewage plant in a tannery area in Xinji City, Hebei Province was introduced into the regulating tank, and the acidic regulator hydrochloric acid was added at the same time, and stirred evenly, so that the pH of the wastewater in the regulating pond was 8; and the alkali regulating agent ( Sodium bicarbonate), the stirrer stirs evenly, and the alkalinity of regulating waste water is 2000mg / L;

[0202] 2. Anaerobic treatment

[0203] By connecting the pipeline and the sewage pump installed on the pipeline, the pretreated and mixed wastewater in the adjustment tank is introduced into the anaerobic tank for anaerobic treatment, and the hydraulic retention time in the anaerobic tank is controlled to 16h, so that the concentration of volatile fatty acids in the effluent of the anaerobic tank is ≤ 900mg / L;

[0204] 3. Pre-aeration treatment

[0205] Pass the effluent after anaerobic treatment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com