Preparation method of glassy carbon material based on polymer prepolymer precursor

A technology of polymer prepolymer and glass carbon, which is applied in the field of glass carbon material preparation based on polymer prepolymer precursor, can solve the problems of long curing period and high product porosity, and shorten curing cycle and process conditions. The effect of optimizing and improving material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The phenolic resin was dissolved in ethanol at a mass ratio of 30wt%.

[0034] The prepared polymer precursor solution in the mold is placed in a vacuum ultrasonic degassing device, and a vacuum pump is used to evacuate the ultrasonic degassing device to pre-remove the gas in the environment; the polymer precursor solution is heated in a water bath, to 5 o The heating rate of C / h is raised to 80 o C, insulation.

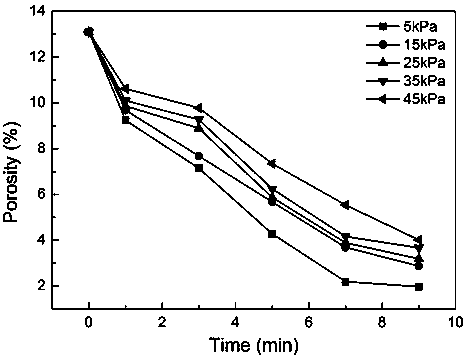

[0035] Ultrasonic degassing is carried out to the polymer precursor solution that is in the heat preservation state in the water bath, specifically: at 80 oC. Keep the vacuum ultrasonic device in a vacuum state with a vacuum degree of 5 kPa -45kPa. At the same time, turn on the ultrasonic degassing function of the device, the ultrasonic frequency is 20kHz, the ultrasonic power is 240W, and the vacuum ultrasonic time is 1-9min.

[0036] The polymer precursor solution after vacuum ultrasonic degassing was degassed with 5 o C / h heating rate from 80 o C warm...

Embodiment 2

[0041] The phenolic resin was dissolved in ethanol at a mass ratio of 40wt%.

[0042] The prepared polymer precursor solution in the mold was placed in a vacuum ultrasonic degassing device, and heated in a water bath in a vacuum environment to 5 o The heating rate of C / h is raised to 70 o C, insulation.

[0043] Ultrasonic degassing was performed on the polymer precursor solution kept warm in a water bath. Specifically: at 70 o C. Keep the vacuum ultrasonic device in a vacuum state with a vacuum degree of 5kPa; at the same time, turn on the ultrasonic degassing function of the device, the ultrasonic frequency is 20kHz, and the ultrasonic power is 240W. The vacuum ultrasonic time is 7min.

[0044] The polymer precursor solution after ultrasonic degassing was degassed at 5 o C / h heating rate from 70 o C warming up to 100 o C, keep warm for 2h; take 5 o The heating rate of C / h is raised to 120 o C, keep warm for 2h; o The heating rate of C / h is raised to 150 o C, keep ...

Embodiment 3

[0049] The phenolic resin was dissolved in ethanol at a mass ratio of 50wt%.

[0050] The prepared polymer precursor solution in the mold was placed in a vacuum ultrasonic degassing device, and heated in a water bath in a vacuum environment to 5 o The heating rate of C / h is raised to 90 o C, insulation.

[0051] Ultrasonic degassing was performed on the polymer precursor solution kept warm in a water bath. Specifically: at 90 o C. Keep the vacuum ultrasonic device in a vacuum state with a vacuum degree of 5kPa. At the same time, turn on the ultrasonic degassing function of the device, the ultrasonic frequency is 20kHz, and the ultrasonic power is 240W. The vacuum ultrasonic time is 7min.

[0052] The polymer precursor solution after vacuum ultrasonic degassing was degassed with 5 o C / h heating rate from 90 o C warming up to 100 o C, keep warm for 2h; take 5 o The heating rate of C / h is raised to 120 o C, keep warm for 2h; o The heating rate of C / h is raised to 150 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com